Interview: Eric Dominguez, Caesars Entertainment

TriplePundit attended Sustainable Brands 2014 in San Diego this month. These videos are part of our coverage. Find the rest here.

I once sensed irony in pairing the concept of sustainability with a Las Vegas based entertainment empire. But Caesars Entertainment has long been recognized as a leading sustainability reporter as well as a company with a progressive vision. There's more going on as well. In this interview, Eric Dominguez talks about the big picture at Caesars - energy, water and waste as well as engaging their employees to care and take sustainability seriously.

Heinz and Ford to Team Up on Rolling Green Tomatoes

You could say that, at least until now, cars and tomatoes have basically nothing in common. Tomatoes go from green to red as they ripen, and cars, well, they seem to be getting greener. As part of this trend, Ford is one of several companies that have been pursuing a viable bio-based plastic that could substitute for the petroleum-based plastics that dominate the industry today. Indeed, as cars continue to reduce vehicle weight in order to improve fuel economy, the use of plastics is becoming ever more common.

Ford formed a collaboration two years ago with Heinz, Nike, Coca-Cola, Procter and Gamble and others, along with the World Wildlife Fund, in the Bioplastic Feedstock Alliance. Their stated goal was to develop a 100 percent plant-based PET, a common type of plastic used in soft drink and water bottles.

The intent, from Ford’s perspective, has been “is to develop a strong, lightweight material that meets our vehicle requirements, while at the same time reducing our overall environmental impact.” So says Ellen Lee, a Ford plastics research technical specialist.

Now they have apparently hit pay dirt. In what appears to be a marriage made in heaven, Heinz was looking for an innovative way to recycle and repurpose peels, stems and seeds from the more than 2 million tons of tomatoes the company uses annually to produce its best-selling ketchup.

Says Vidhu Nagpal, associate director of packaging R&D for Heinz: “We are delighted that the technology has been validated. Although we are in the very early stages of research, and many questions remain, we are excited about the possibilities this could produce for both Heinz and Ford, and the advancement of sustainable 100 percent plant-based plastics.”

Plant-based plastics still have many of the same environmental issue as oil-based plastics, as both Pepsi and Coca-Cola learned when they announced the use of plant-based PET in their bottles. That is to say, they are not biodegradable, they cause litter, and they can leach chemicals into the soil and water. All of these impacts can be minimized in a closed-loop recycling environment, though some bottles always escape. Still, the substitution of plant-based feedstock is definitely a significant improvement, since it has a lower carbon footprint and reduces the demand for fossil fuels. According to the Energy Information Administration, 190 million barrels of oil were used in 2010 to make feedstocks for plastic. That represents close to 3 percent of the country’s oil consumption.

The announcement with Heinz is just one more step in Ford’s journey to incorporate more sustainably produced materials in their vehicles. Their bio-based portfolio now includes eight materials in production, including: coconut-based composite materials, recycled cotton material for carpeting and seat fabrics, and soy foam seat cushions and head restraints. Other efforts to find lightweight, natural materials have included investigations into the use of feathers in a composite structural material. The company also includes a considerable amount of recycled materials in their products.

We’ve long known that tomatoes can be good for you, but now it appears that they could be good for the environment as well.

Image credit: Andrew Seaman: Flickr Creative Commons

RP Siegel, PE, is an author, inventor and consultant. He has written for numerous publications ranging from Huffington Post to Mechanical Engineering. He and Roger Saillant co-wrote the eco-thriller Vapor Trails. RP sees it as his mission to help articulate and clarify the problems and challenges confronting our planet at this time, as well as the steadily emerging list of proposed solutions. His uniquely combined engineering and humanities background help to bring both global perspective and analytical detail to bear on the questions at hand.

Follow RP Siegel on Twitter.

Do Perovskites Hold the Keys to Ubiquitous Solar Energy?

What are perovskites? Perovskite is a relatively inexpensive mineral composed of calcium titanate (titanate is a salt composed of titanium and oxygen). It is attracting attention in the renewable energy space for its semiconductor properties.

The Department of Energy announced $10 million in new research and development (R&D) funding for six research teams during the SunShot Grand Challenge Summit 2014 two weeks ago. The teams will use the funds to develop cheap, efficient thermochemical energy storage (TCES) solutions for utility-scale concentrating solar power (CSP) systems. For at least two of the six, perovskite minerals are to serve as the energy storage medium.

Finding a cheap, efficient means of storing energy produced by CSP plants would be a major milestone for the fast-growing renewable energy sector, and that's probably an understatement. Perovskites may be more than the key to cheap energy storage for CSP, however.

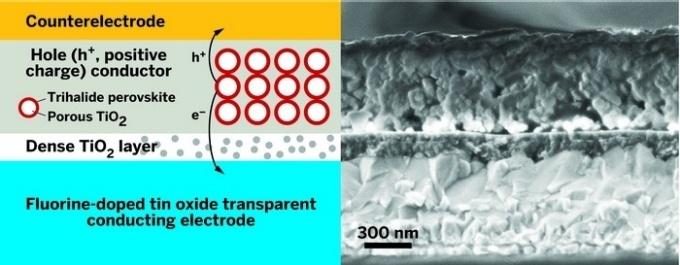

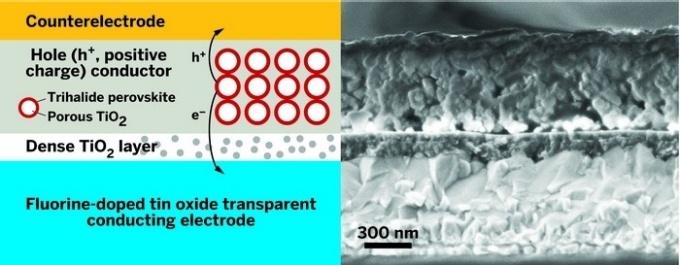

A class of lamellar organic-inorganic minerals found in igneous and metamorphic rocks, perovskites have generated intense interest among photovoltaic (PV) energy researchers as well.

A semiconductor, perovskite PV cells can essentially be “painted” on to almost any type of surface – flexible or rigid. Solar PV researchers having been making significant strides in boosting the energy conversion efficiency and lowering the cost of producing perovskite PV cells, leading one prominent researcher to assert that they “are poised to 'break the prevailing paradigm.'”

Perovskites and CSP energy storage

A total $4.45 million of the $10 million in CSP ELEMENTS program R&D funding announced by DOE during this year's SunShot Grand Challenge Summit is being allocated specifically to investigate the use of perovskites in CSP-thermochemical energy storage solutions.

Awarded $1 million, the Colorado School of Mines (CSM) will lead an R&D team that also includes Abengoa and the National Renewable Energy Laboratory (NREL). Joined by colleagues Robert Braun and Robert Kee, Prof. Greg Jackson, the head of CSM's mechanical engineering department, will lead a two-year R&D effort “to work on materials development and system design of the novel energy storage concept,” CSM explains in a news release.

Focusing more on commercial aspects, Abengoa's Christina Lopez is responsible for systems integration and techo-economic analysis. NREL's Zhiwn Ma will lead other research partners in an effort “to adapt NREL's near blackbody solar energy design to operate as a reactor for capturing the sun's energy as storable thermochemical energy in perovskite particles.”

Awarded R&D funding of $3.45 million, Sandia National Laboratories' Drs. James Miller, Andrea Ambrosini and Clifford Ho will lead research into a CSP-TCES solution in which the heat of concentrated sunlight is to be captured and stored by “a falling curtain” of perovskite particles. Researchers from Arizona State University, the Georgia Institute of Technology, and Saudi Arabia's King Saud University round out the R&D team.

Through the ELEMENTS program, DOE is looking to leverage public and private sector resources to develop CSP-TCES systems that can provide energy storage at a cost of $15 per kilowatt-hour-thermal (kWht) or less and can operate at temperatures greater than or equal to 650ºC (1170ºF).

Perovskites and solar PV

Besides CSP-TCES, solar PV researchers increasingly see perovskite PV cells as offering an ideal combination of price and performance. Energy conversion efficiency has jumped from a few to 16 percent, with 25 percent conversion efficiency considered easily within reach.

Furthermore, though not yet produced at commercial scale, all signs indicate that the cost of producing perovskite PV cells in bulk will be much lower than for c-Si PV cells, the cheapest and most efficient available on the global market today. Costs are coming down as researchers focus on using less expensive materials and improving production processes.

As Chemical & Engineering News (C&EN) reporter Mitch Jacoby quoted University of Notre Dame chemistry professor Prashant V. Kamat in a February 2014 article:

“The simplicity of making solar-cell components via liquid-phase chemical reactions and depositing the materials by methods such as spraying and spin coating may make it possible for solar-cell manufacturers to eventually replace clean rooms and sophisticated manufacturing equipment with simple benchtop processes.”

In that same article, C&EN reported on University of Oxford physicist Henry J. Snaith, who is looking to commercialize perovskite PV cell technology. Also the leader of the Oxford Photovoltaic & Optoelectronic Device Group, Snaif has launched Oxford Photovoltaics, which is focusing on developing building-integrated applications of perovskite PV cells.

Tempering all the enthusiasm a bit, Snaith told C&EN that “it’s tough to predict where this technology will end up.” Yet based on perovskites' inherent properties and the pace of recent R&D advances he added, “So long as we can improve the stability of this technology, I would say we are witnessing the emergence of a contender for ultimately low-cost solar power.”

*Image credits: 1) Wikimedia Commons; 2) Sandia National Laboratories ; 3) Journal of Physical Chemistry Letters

How to Fight Greenwashing: The Value of Third-Party Certification in Green Building

By Elise Hunter

I recently came across a line of roofing tiles advertised as “lower carbon footprint.” This nebulous claim begged a string of questions. Lower than what? How much lower? What scopes of emissions are included in the carbon footprint? Was it verified by a third party? Of course, none of this information was provided, because the statement was a classic example of greenwashing: a claim so vague that it cannot be proven or disproven.

Greenwashing is rampant. Overzealous marketers know that sustainability is gaining importance in the minds of consumers and corporate buyers, and they sometimes make claims that are vague, misleading, unquantifiable, or even completely immaterial to the product or industry. Bogus or unsubstantiated statements like “all-natural,” “eco-friendly,” and even “sustainable” are all too easy to find on everyday products, from cleaners to shampoos to paints.

The green building industry is a hotbed for greenwashing, reflecting the fact that green building is defined by a dizzying array of attributes. These attributes range from the material ingredients and relative toxicity of products, to the environmental impact of material extraction, to the actual performance of the building itself in its energy, water and resource usage.

To tamp down this greenwashing and spur environmental innovation, overarching green building standards such as LEED, Green Globes, and GreenPoint Rated have gained wide prominence. Their aim is to assess the “greenness” of buildings based on a comprehensive set of factors, as determined by third-party auditors. Underlying this building-level recognition are product- or material-specific certifications. Certified products or materials often bear a seal, or “ecolabel.” Architects, developers, designers, and manufacturers can look to these certification programs and ecolabels in order to meet criteria for green building standards.

One example is the internationally recognized Forest Stewardship Council (FSC), which maintains a standard and certification program for “responsibly-managed” forests, and their corresponding timber and wood products, for buyers who don’t want to support deforestation. The LEED standard gives credit for the use of FSC certified wood in framing, flooring and interior finishes. The FSC standard is periodically reviewed by its knowledgeable member base to stay current with emerging forestry practices, new environmental issues and societal expectations.

In order to earn FSC certification, a forest management or wood products manufacturing company must be assessed by a third-party certification body (CB). My company, SCS Global Services, has been an active CB for FSC since FSC’s founding in 1993. The FSC standard is one of the most rigorous standards in the marketplace today; many others are less stringent. Despite the wide range in the quality and rigor of certification programs and ecolabels out there, at first glance it is often difficult to decipher the difference.

In order to be truly credible, green claims should be specific, measurable, relevant to the product, and confirmed by a third party CB. These principles are affirmed by the Federal Trade Commission’s 2012 Green Guides, which provides guidance for green marketing. The Guides now include a section on certifications and seals of approval, which encourages specificity of claims, and disclosure of the CB’s relationship to the company. While the Green Guides drive more credibility in claims, there are still gaping holes, such as a lack of guidance on use of the word “sustainable.” The FTC periodically imposes fines on some of the most flagrant greenwashers, but there is still much work to be done.

The verification of claims by a third-party CB can discourage exaggeration, white lies and other greenwashing pitfalls that occur when a company certifies its own products. CBs also tend to bring deep expertise on the standards to which they certify, while the product manufacturers may only have surface-level knowledge of the standards. To ensure their impartiality and confirm their competence and knowledge, the CBs themselves are regularly audited under an “accreditation” procedure governed by the owner of the standard. For example, SCS is annually audited by Accreditation Services International (ASI), the body that evaluates and determines a CB’s competence, or accreditation, to a host of standards such as FSC.

In an ideal situation, a green building would be chock-full of green elements and products, all of which have been verified by a third-party CB for specific and relevant claims, and the building itself would also be assessed by a third-party expert. In this sense, green building standards are “meta” standards. However, the world of sustainability claims, in the building industry and beyond, is still confusing and daunting. Resources such as The Ecolabel Index, The International Trade Centre Standards Map and SCS’ Green Products Guide are a good start. And of course, approaching any sustainability claim with a little research, common sense, and a healthy dose of skepticism can’t hurt.

Elise Hunter is a Marketing & PR Specialist in the Natural Resources Division of SCS Global Services.

Social Media for Social Entrepreneurs

By Shannon Houde

Social media can be a social entrepreneur's best friend -- a fascinating, engaging best friend, but a demanding one too. How can a busy person make the most of it without becoming its slave? In my work as a sustainability career coach, I've learned that social media is the most powerful tool at my disposal to market my services and leverage my brand. It's definitely not optional. And while it's easy to use, using it well is not so easy.

Here's a little about my experience using LinkedIn, Twitter, Facebook and blogs to build a sustainability business. I'm no expert, but by sharing what works for me, maybe I can help you gain insight on what might work for you.

My social media story

A year after launching my business, Andy Cartland, Acre Resources' managing director, told me I'd better get on Twitter. My response? I was way too busy to be bothered with a little blue bird. I had a website, what more did I need? The answer was: Quite a lot. The website alone was not enough to maximize my online profile or gain the traffic through search engine optimization (SEO) that I needed. And so -- with some trepidation -- I joined the social media world, and slowly but surely and started to see results.

That was three years ago. Since then, it has become invaluable to my business for three key reasons:

- It helps me stay informed of what's new and hot in my sector to play on what others are interested in to stay ahead of the curve

- It helps me build my own brand credibility through my thought leadership, to get my voice out there

- It helps me connect with others to nourish my networks. Word of mouth is everything!

The benefits of reaching out to the world in this way did turn into growth in my client numbers, and I found myself spending more and more time writing blogs, sending tweets and posting LinkedIn updates. It was starting to take me away from the client coaching work I loved. So in 2012, I hired someone to help me manage the flow, and in 2013 took on an additional staff member to implement a more rigorous social media strategy.

We now produce four original content blogs per month that we promote through the major social networks. I've posted over 1400 tweets and gained 920 followers (which is a pretty good ratio!), and over the past 20 months I've had 30,000 page views on Facebook from 7,000 unique users. I write columns for Greenbiz, CSRwire, 2Degrees and, of course, Triple Pundit. These days, a social media strategy is your marketing strategy.

What I've learned

- Language is important. Use the words that will draw people to your services. My clients don't know they're looking for looking for a career coach, they are looking for jobs. So instead of blogging about coaching, I regularly post 'Hot Jobs', which comprise 25 percent of my site's traffic. I continue to watch the analytics of my site and blogs to see what key words are getting the most hits which helps me keep up to date in relevant content – the latest was “innovation."

- Monitor your traffic. The goal of social media marketing for me is to get people to come to my website and sign up for coaching. We track my site's traffic sources to figure out how to best target potential clients. Monitoring is crucial to a successful social media strategy so that you know what's working and what isn't. While it's not easy to track the number of directly converted clients, we can see trends, growth, hits and website referrals. There are great tools on the web to help you do this easily like Sprout Social.

- Manage your schedule. Managing your week in social media will make a big difference to your impact and your sanity. From developing a content calendar to coming up with blog ideas, writing, editing, posting and promoting, there's an awful lot to do. Be realistic about what you're good at and enjoy, and outsource the rest. Be organized though and have a system or catalog for filing great articles you have read or want to blog about in the future. I use Delicious.com that allows you to tag articles with key words and categories.

- Make use of online managers. There are many services out there -- paid for and free -- that will allow you to manage your various social media accounts from one window. I use Sprout Social to consolidate and schedule my content, Hootsuite to post, and LinkedIn tags to do group postings on content.

In summary, social media does work, but it's hard work too. You need commitment and patience. It can take 12 months to feel like you're getting traction, it requires planning and a strategy, it often means getting some outside help, and it definitely needs a strong monitoring regime to help you learn from what's working and what's not.

Do you agree with my social media strategy tips? What works for you? Let me know in the comments section below or contact me if you want more help building your social enterprise’s brand as a social entrepreneur. You can also follow us on Facebook, Twitter and LinkedIn to receive our latest updates.

Shannon Houde is founder of Walk of Life Consulting, the first international career coaching business focused solely on the environmental, sustainability and corporate responsibility fields.

Image credit: Jason Howie, Flickr

A 'How-to' Guide for Successful Supply Chain Collaboration

By Elisabeth Comere

Corporate sustainability strategies are evolving and it is no longer enough to get our own house in order. We must look beyond the boundaries of our own operations and consider the social and environmental impacts of the entire value chain from material sourcing through to recycling. This is not a call for altruism, but rather a prerequisite for long term business continuity and a greater competitive advantage.

Over the next 20 years, the global middle class will increase to an estimated three billion putting more pressure on an already fragile and resource constrained environment. It is crucial for companies to shift their mindset from individualistic “wins” to holistic “triumphs” hence, invest into resource efficient value chains with bigger ambitions and better returns. The theoretical approach I speak of is collaboration, a method used to consider opportunities, assess risks, set targets for sourcing, reducing our carbon emissions and material recovery to build a secure and resilient supply chain while creating long-term value for our customers.

To remain competitive and bring long term value to customers, we need to develop new and innovative products while delivering cost and operational efficiencies. We need to support customers to avoid regulatory risks (i.e. packaging bans) and raise public awareness around renewability and recycling in order to increase packaging recovery rates – which will ultimately help further their brand equity. I believe these are needs that not only face Tetra Pak, but many other companies as well. Nevertheless, they are big tasks; none of which can be tackled alone. However if we function in symbiosis with our suppliers, customers, business partners and other stakeholders, we can develop a sustainable supply chain and accomplish our goals.

Establishing effective and sustainable collective actions is easier said than done. Competitive interests, dissimilar organizational cultures, and conflicting objectives are just a few factors that can undermine success. With careful planning, these pitfalls can be avoided. We have learned much about collaboration in the pursuit of our sustainability goals and consider these five factors a key to success:

The “how-to” guide for collaboration

- Commitment from the Top: Getting support from executive management is crucial to moving things forward. Without the CEO on board, resources may not be sustained to carry the initiative through to completion.

- Multi-party effort implies bringing the right partners to the table: The right partners whether they come from public or private sectors, will share a common sense of risk, responsibility, benefit among interested parties, have “skin in the game” via a financial commitment, and have corporate targets or commitments that compel them to act. We have found that it is not always clear who the right partners are from the outset but coming up with the “Ask” first, helps us pinpoint the influencers we need involved.

- Broad representation and buy-in, internally and externally: To bring partners on board, the “Ask” must be supported by a strong business case that generates shared benefits and appeals to core interests. This is imperative to build buy-in with both external partners as well as internal decision-makers. The challenge in a multi-stakeholder process is to appeal to a range of perspectives. Success of collective models will depend on a two-way (or multi-way) dialogue which leads to stronger outcomes than those achieved through unilateral action.

- Clearly articulate objectives and terms of reference: Come to an agreement at the beginning of the collaborative process to avoid future conflict.

- Sustainable funding: Allocate project costs fairly among parties and provide sufficient funding to support the initiative over time.

In other words, collective action is about coordinated engagement among interested parties within an agreed-upon process in support of common objectives.

Procter & Gamble case study

Procter & Gamble leveraged collaborative efforts to create and promote an energy efficient detergent for cold water laundry. The company worked with its suppliers to develop a low-temperature, concentrated washing detergent and brought washing machine manufacturers into the fold to provide consumers with widespread access to low-temperature settings. Government and NGO partnerships were leveraged in the rollout of an awareness campaign to encourage consumer uptake. As a result of this value chain collaboration, there has been a significant reduction in energy use and greenhouse gas emissions and a transformation of consumer behaviour and expectations.Carton Council case study

The Carton Council was first established with commitment from carton packaging manufacturers who had a common goal to expand carton recycling throughout the U.S. Recognizing it couldn’t do it alone, the Council actively engaged in cross-sector public-private collaborations to establish infrastructure for collection, appropriate sorting technology, consumer awareness campaigns, and a sustainable business model for the collection and recycling of carton packages. This is a strategy that breaks the bounds of traditional partnerships and is having a dramatic impact on expanding carton recycling access in the US.

Tetra Pak case study

Tetra Pak’s renewability strategy follows a similar trajectory in which we define a gold standard for sourcing raw materials. We engage with our suppliers, NGOs as well as industry partners to build a sustainable supply of input materials that we rely on for packaging material production in all markets where we operate. By developing a chain of custody for our paperboard fiber, we can trace where it is coming from and how they are managed which will allow us to safeguard against social and/or environmental disruptions.

Industry partners have also been critical for us to deliver on our green innovation ambitions. Tetra Pak partnered with Braskem, one of the world’s leading biopolymers producers, to develop polyethylene from sugar cane derivatives. A cap composed of the bio-based plastic was first launched in partnership with Nestlé Brazil in 2011 and we are now using the material to replace fossil-fuel derived plastic within our packages’ material. In February, Tetra Pak piloted the use of bio-based LDPE in Coca-Cola Brazil’s Del Valle juice beverage packaging and there are already plans to extend this successful pilot to other customers. This is a great example of collaboration that is helping us get closer to our ambitious renewability and climate goals.

Seizing opportunities in a resource constrained world

According to the World Business Council for Sustainable Development, we will need to increase resource efficiency tenfold to keep pace with a burgeoning population. Seizing opportunities in a new era of collaboration to produce the leanest, most resource-efficient value chains is not a choice, it’s a competitive imperative. A value chain mindset recognizes that a company is no stronger than its weakest link and it can only go so far working alone. Strengthening the chain by working together can hedge against resource scarcity, regulatory risk and consumer backlash and lead to innovative product lines, new markets and enhanced brand value. What better reason do you need to look beyond the fence?

Image credit: Flickr/gi

Elisabeth Comere is the Director of Environment and Government Affairs for Tetra Pak in North America, the world leader in packaging and food processing solutions. She joined the company in 2006 as Environment Manager for Europe where she helped define and drive Tetra Pak’s environmental strategy. She joined the North American operations in 2010, focusing on advancing Tetra Pak’s commitment to sustainability in the U.S. and Canada, and she is active in various industry and customer packaging and sustainability initiatives. Elisabeth previously served as a political adviser to a member of the European Parliament in Brussels, Belgium, and headed the environment department of the Food & Drink Industry group in Europe.

Europeans wasting €2.4bn on annual energy bills

European households are losing €2.4bn, wasting 12 TWh of energy annually, and emitting an extra 3.3m tonnes of CO2 – more than enough to power every home in five European countries.

Revealed in a global study by Opower, a provider of cloud-based software to the utility industry, the findings report that Germany has the most to gain by adopting behavioural energy efficiency programmes due to its large population and high energy costs. UK, France, Italy and Spain are the next countries ranked by greatest potential.

The study, “Unlocking the Potential of Behavioural Energy Efficiency in Europe” reported that Germany has the potential to save up to 2.2 TWh annually. This is enough to power all the homes in Hamburg for a year and represents €521m savings in utility bills and through simple behavioural change, the UK could save up to 2.1 TWh of electricity and gas annually, impacting nearly 22m households.

Commenting on the findings, John Webster, vp marketing and strategy, Opower EMEA said: “Behavioural energy efficiency remains largely untapped by much of Europe – clearly there is a real opportunity here for many countries to cost-effectively cut their greenhouse gas emissions and increase consumer affordability.

“Take Germany as a prime example. Here is a market that has long invested in green technologies to reduce carbon usage on the supply side. Yet our study clearly reveals the size of their energy efficiency prize and the importance of demand side management, with consumer savings instead of consumer costs. Germany has the most potential to save energy simply by focusing on the role that individual consumers and businesses can play through informed behavioural change.”

According to Opower, behavioural energy efficiency measures could help countries turn around the shortfall to the European Union’s Energy Efficiency Directive, which has set the goal of a 20% reduction in energy use by 2020.

Picture credit: © Borislav Bajkic | Dreamstime.com

Fashion Futures: Resource Constraints and Sustainable Design

The fashion business is close to being a $2 trillion industry globally, and with a growing population predicted to reach 9 billion people by 2050, demand for apparel is going to only grow as we head into the future.

The strain on resources to meet burgeoning demand has smart businesses in the industry taking a long-term view as to how the fashion landscape will be forced to change, since those constraints are almost certainly going to disrupt the business-as-usual model we have today, which is often of an industry built around a cheap and disposable product.

So how will peering into the future drive the industry to adapt to growing resource constraints, and how will this impact the design process to make the fashion industry more sustainable? Furthermore, how will the next generation of fashion designers respond, and drive the industry to meet the challenge?

In order to prepare for the future, you have to have some sense of what to expect even if it's not possible to predict precisely how it will unfold. Initiatives like Fashion Futures, a joint project undertaken in recent years by Forum for the Future and Levi Strauss & Co., looked ahead to 2025 and envisioned four different plausible scenarios for the industry.

Scenario planning is a useful tool companies can use to help "future-proof" their business by allowing them to be in a position to plan and adapt to a number of different possibilities. In the case of Fashion Futures, scenarios range, for example, from an industry organized around local communities and short supply chains, on the one hand, to one organized around a highly collaborative global industry with established standards, on the other.

But in each scenario, the project revealed five key lessons, all of which are organized around change for the industry. A successful company will need to:

- Prepare now for a radically different and uncertain future

- Seize the opportunity to be a trailblazer

- Put change into practice

- Look out for unexpected competition

- Develop skills for a new world.

Most importantly, the project determined that, "The scenarios demonstrate the urgent commercial imperative for the industry and the businesses within it, to rise to the challenge of the future and become more sustainable." So no matter what, the fashion industry is in the throes of a paradigm shift.

We interviewed Desirae Early, Levi Strauss & Co. manager of Sustainability Strategy and Innovation, to discuss resource constraints facing the fashion industry, and to learn how design and innovation can address the most pressing problems.

Fashion and resource constraints

In the Sustainably Attired series on Triple Pundit, we have already described the importance of cotton to the fashion industry and how it places great demands on the environment, in terms of water use. LS&Co.'s Early noted that in some places in the world, water is already a critical constraint, and that cotton crop yields fluctuate dramatically with changes in weather patterns -- having a material effect on raw material prices.

Other key constraints Early identified are fossil fuel-based energy sources. The effects here, she explains, are the negative impacts of unchecked CO2 emissions which will trigger large-scale economic, social and environmental consequences for their business and the communities in which they operate. But those environmental factors aside, oil scarcity and higher prices will directly impact raw material creation, since polyester -- which in combination with cotton, represent the two most important fibers used in the fashion industry -- is an oil derived product.

Another constraint is the opportunity cost of agricultural land. If more land is given over for growing food crops or producing biofuels instead of producing textile fibers, it will place another constraint on the supply chain for the fashion industry.

The impacts of both fossil fuels and water use are largely felt in the raw material supply chain in the creation of fabrics, before a garment or a piece of footwear is created. Research conducted by Nike found that growing cotton, harvesting rubber, raising livestock for leather and extracting oil for polyester -- coupled with materials processing activities such as the dyeing and finishing of fabrics -- accounts for 54 percent of total energy use, 83 percent of water consumption and 56 percent of GHG emissions in producing apparel.

This means that as raw material inputs rise to meet growing demand, it will no longer be economically viable to sell cheap clothing. LS&Co.'s Early told us that water and energy prices are increasing in many parts of the world where production occurs, necessitating that only, "by decreasing the water inputs and transitioning to materials that use less water and energy in production, we can make clothing with a lower environmental impact at a better long term price."

Addressing these considerable inputs, and in order to mitigate the impact, Levi's became a "pioneer member" of the Better Cotton Initiative, which is working to reduce inputs of water, as well as pesticides and focuses on making global cotton production better for the people who produce it. As Early told us:

"We must decouple the growth of our business and our water needs if we want to continue leading into the future."

However, even beyond the creation of fabrics, there is still considerable water use in the garment manufacturing process too. Levi's has also addressed efficiency in this realm, by efforts in Levi’s® Water<Less™ program. Here, the company has significantly reduced the amount of water used to make its products, such as removing water from the stone-washing process and moving away from multiple wet-cycle processes. These efforts have saved the company more than 770 million liters of water in the production of over 62 million garments.

Embracing sustainable design

Product design itself is integral to the fashion industry in avoiding the impact of material resource constraints. To help quantify 'sustainability' in product design, the Sustainable Apparel Coalition, whose current membership includes many household brands such as LS&Co., Nike, Patagonia, and Gap among many others, developed the Higg Index. Based on three modules (facility, brand and products), this sustainability self-assessment tool aims to asses current performance and drive behavior for improvement.

The Higg Index includes a beta tool in the product module to help designers understand the impact of products they are designing. Known as the Rapid Design Module (RDM), it aims to educate and provide quick directional guidance to apparel and footwear designers during the product creation process concerning the potential environmental impacts of their design solutions, while incorporating a product lifecycle approach.

"We think that standards, like the Higg Index, are extremely important to changing the apparel industry," Early told us. "We have used it benchmark our own brands and are working with the Sustainable Apparel Coalition to expand usage and coverage with the index."

Early also explained that in the design process, there is plenty of opportunity to make clothing longer lasting and more easily recyclable. For example, LS&Co.'s Dockers® Wellthread™ collection – a small collection launched in 2013 – uses an innovative new long-staple yarn designed to hold up through the recycling process without sacrificing the strength of the cloth. Additionally, the company's Waste<Less collection incorporates recycled water bottles, while they have a small range of jackets made from re-purposed military parachutes.

Other companies like Nike, are also designing products with recycled materials. Brazil's world cup soccer team will be wearing shirts made from recycled polyester fibers for example, while outdoor clothing specialist Patagonia has a range of fleece's that are made from 80 percent recycled material.

Better use of raw materials and water, increased use of recycled fibers, and designing clothes that are easy to recycle at end-of-life, are all elements of smart design that the fashion industry is increasingly paying attention to; and the importance of training the next generation of designers to incorporate these elements of sustainability into clothing design is paramount, Early says.

So, as well as developing innovative materials and processes, LS&Co. is leading an effort in the education process too. Two years ago, the company began a relationship with the Rhode Island School of Design with the goal to incorporate more sustainable practices in fashion design.

"This past winter, our relationship expanded to create a Designer in Residence program at RISD, so that members of Levi Strauss could work with up-and-coming talent on new, innovative ways to approach design processes and creation methods, while keeping sustainability a priority," Early says. "We believe that by working with designers early on to learn about and promote environmentally friendly practices, they will then incorporate those lessons further into their careers."

Image credit: Pexels

Oceana: Traceability Is Key to Fighting Seafood Fraud

By Beth Lowell

Seafood is one of the most popular food choices for Americans, with the United States coming in only behind China as the largest consumer of seafood in the world. What many people don’t know, however, is how complex of a path our seafood travels in the supply chain, with little to no information making it to the final point of sale. This lack of information can cause confusion for consumers, and also increases opportunities for illegal activities like seafood fraud, where seafood is misrepresented in any number of ways, including swapping out one fish for a completely different species. The key to stopping this bait and switch is traceability, or tracking seafood from the fishing boat to your dinner plate.

Traceability is an important issue for all food, but seafood is of particular concern, as the recordkeeping and tracking systems in the seafood supply chain have historically lagged behind other food industries like produce and beef. Seafood fraud can happen for a variety of reasons, but most often for financial gain, as it’s been found that commonly swapped species like grouper and wild salmon can cost up to twice as much as their cheaper counterparts. This fraud can happen at any step of the supply chain – from the fishermen, to the processor, or even by the restaurant itself. Seafood fraud undermines consumer and industry sustainability practices and can result in a myriad of health problems. It also hurts honest fishermen and businesses that play by the rules and are undercut by illegally caught and fraudulently labeled fish flooding the U.S. market.

Last year, Oceana released one of the largest seafood fraud studies in the world, which found that 33 percent of more than 1,200 fish samples from across the nation were mislabeled according to Food and Drug Administration guidelines. Tuna and red snapper were among the most mislabeled fish species — at 59 and 87 percent, respectively. In fact, out of 120 samples labeled “red snapper,” only seven were actually true red snapper. “White tuna” was another huge culprit; 84 percent of the samples purchased from sushi bars were found to be escolar, an oily fish that can cause serious digestive problems and carries a health warning from the FDA. In some cities, more than 50 percent of the fish tested were mislabeled.

Furthermore, another recent study found that between 20 percent and 32 percent of seafood imported into the U.S. was likely due to illegal, unreported and unregulated (IUU) fishing. These pirate fishermen often use illegal gear, fish in prohibited areas or catch endangered and threatened species. Illegal fishing is a major threat to the worldwide fishing industry, undermining decades of conservation measures and provoking billions of dollars in economic losses.

A clear solution to these problems exists. Traceability, tracking seafood from boat to plate, would help ensure the fish a diner orders is in fact what the menu says. The federal agencies that work on food, fish and illegal wildlife trade need to come together to devise specific requirements for all seafood sold in the U.S. Much of the information required to implement a seafood traceability scheme is already reported when a fisherman brings their catch to port; the key is having this information follow the fish to the end consumer and creating clear rules at the U.S. border. Requiring the basic who, what, where, when and how of a product being sold, through proper documentation and processes, is a key step to ensure consumer confidence and create clear rules for entry of legal products.

Now more than ever, government officials need to take notice and work to prevent seafood fraud. In June, ocean leaders from around the globe will convene in Washington, D.C. at the Our Ocean conference hosted by Secretary of State John Kerry. This conference will provide a key opportunity for the U.S. to promote ideas that will have huge impacts on global ocean conservation, including seafood traceability. The government should do everything in its power to fight seafood fraud and illegal fishing and ensure that the seafood sold in the U.S. is safe, legally caught and honestly labeled.

Image courtesy of Oceana

Beth Lowell is the seafood fraud campaign director at Oceana, the largest international organization focused solely on protecting the world’s oceans.

Horrors! Seattle is Moving to a $15/hour Minimum Wage

Seattle’s move to phase-in an increase in the minimum wage to $15 per hour (from the current $9.32) is described variously as: audacious; a “step too far;” a misguided experiment; a worthy experiment; built on dubious economics; and a move that will “destroy the economy.”

It can’t be all of that, can it? The volume of the punditry and spinning on this one is shrill, and the scope of the alarmed, breathless opinion and analysis by the “very serious people” about Seattle’s bold move obscures the bottom line: A region is trying to do the right thing for its workers in these parlous economic times. (Conflict of interest alert: The author lives in — and loves — Seattle.)

Will it be the end of the world as we know it? Here’s what happened. On June 2 the Seattle City Council unanimously approved the adoption of a $15 per hour minimum wage, making Seattle the first major city in America to take this type of action to address income inequality. Beginning April 1, 2015, the legislation will phase-in a $15 per hour minimum wage annually over three to seven years, depending on employer size.

"Today we answer President [Barack] Obama's call and the moral call to address the plight of low wage workers," said Councilmember Sally J. Clark, chair of the city council's Select Committee on the Minimum Wage and Income Inequality. "Seattle's new law puts low wage workers on a path to $15 and does it in a way that respects Seattle's love for local businesses and world-leading innovation."

Twenty-four percent of Seattle workers earn hourly wages of $15 per hour or less, and about 13.6 percent of the Seattle community of 652,000 lives below the federal poverty level, according to a University of Washington study. Washington state's minimum wage is currently $9.32 per hour, but effective April 1, 2015, the minimum wage in Seattle will be $10.00 or $11.00 per hour depending on employer size.

"With inaction at the state and national levels, it's time for cities to demonstrate bold and necessary leadership to address income inequality," said Council President Tim Burgess. "Seattle has found a workable and careful compromise that recognizes both the harm caused by stagnant wages and the harm to local businesses should we move forward too quickly."

And that’s the thing — the increase might take as many as seven years to fully kick-in. From that perspective it’s pretty modest. Coastal cities might be underwater by 2022, and we might all be wearing air filtration devices and wet-suits by then as well.

"This is a victory for our movement - it shows the power of working people when we organize and fight for our rights," said Councilmember Kshama Sawant, an economics professor and socialist who was elected to the city council largely on a platform urging a minimum wage increase. "It will inspire millions of people all over the nation to build on this historic step forward. Fifteen in Seattle is just the beginning."

Maybe there is a degree of jealousy and guilt at work: Somewhere deep down in all the hue and cry, weeping, wailing and gnashing of teeth, maybe other cities and their voters are glad that a major city is progressive enough to lead the way. Maybe, as reported by ThinkProgress, they are watching closely — someone had to take that first step.

Image credit: Seattle skyline at night by Kevin Cappis via Flickr