What Do People Want From the ISO 14001:2015 Standard?

By Robert Fenn

First published in 1996, the ISO 14001 standard has grown to become the best known framework for environmental management. Developed by global consensus, it provides a best practice benchmark for organizations of any size, in any sector. Used in supply chains throughout the world, the International Organization of Standardization (ISO) review their standards on an ongoing basis to ensure they are still relevant and effective in a rapidly evolving world.

In 2013, ISO conducted the ‘ISO 14001 Continual Improvement Survey,' the results of which helped form the basis of a draft of the new, updated standard. Garnering feedback from thousands across 110 countries, ISO’s desired outcomes were to find out what value users got from the standard, together with the areas that ISO 14001 needed to strengthen in order to meet future challenges. Below, we look at the expected changes which will finally result in ISO 14001:2015.

What are the expected changes?

The certain change of ISO 14001 is that it will be aligned with other management systems, and will use the Annex SL structure. The emerging changes that we’ve seen in the Committee Draft (CD) include:

Strategic environmental management

There is an increased prominence of environmental management within the organization’s strategic planning processes. A new requirement to understand the organization’s context has been incorporated to identify and leverage environmentally-related organizational risks, including opportunities, for the benefit of both the organization and the environment.

Particular focus is on issues or changing circumstances related to the needs and expectations of interested parties (including regulatory requirements) and local, regional or global environmental conditions that can affect, or be affected by, the organisation. Once identified as critical, actions to mitigate adverse risk or exploit beneficial opportunities are integrated in the operational planning of the environmental management system.

Leadership

In order to ensure the success of the system, there is a renewed emphasis on leadership in the new standard, in-line with ISO 9001:2015. A new clause has been added that assigns specific responsibilities for those in leadership roles to promote environmental management within the organization.

Protecting the environment

The expectation on organizations has been expanded to commit to proactive initiatives to protect the environment consistent with the context of the organization.

The revised text does not define ‘protect the environment’ but it notes that it can include sustainable resource use, climate change mitigation and adaptation, protection of biodiversity and ecosystems, etc.

Environmental performance

There is a shift in emphasis with regard to continual improvement from improving the management system to improving environmental performance. Consistent with the organization’s policy commitments, the organization would, as applicable, reduce emissions, effluents and waste to levels set by the organization.

Lifecycle thinking

In addition to the current requirement to manage environmental aspects associated with procured goods and service, organizations will need to extend their control and influence to the environmental impacts associated with product use and end-of-life treatment or disposal. This does not imply a requirement to do a life cycle assessment.

Communication

The development of a communications strategy with equal emphasis on external and internal communications has been added. This includes requirements on the quality of information communicated and mechanisms to make suggestions on improving the environmental management system by persons working for or on behalf of the organization. The decision to communicate externally is retained by the organization but the decision needs to take into account information reporting required by regulatory agencies and the expectations of other interested parties.

Documentation

Reflecting the evolution of computer and cloud based systems for running management systems, the revision incorporates the term ‘documented information’, instead of ‘documents’ and ‘records.' To align with ISO 9001, the organization will retain the flexibility to determine when ‘procedures’ are needed to ensure effective process control.

What are the timescales for the revised standard?

The Technical Committee responsible is called TC 207/SC1. In a recent meeting in Italy, there were concerns that the Committee Draft of the new standard was too bureaucratic and has vastly increased the need for documentation, which will be a challenge particularly to smaller businesses.

The next step is the development of the Draft International Standard (DIS), which will be open for public comment for a period of 5 months. Currently, this is expected to be available in mid-2014.

Once the balloting period is over, comments will then be grouped and adjustments made for the Final Draft International Standard (FDIS), which tends to be little different from official, final revision. Assuming things stay on track, the standard should be available in mid-2015. Certainly, with ISO 14001 certification being linked to demonstrating competitive edge recently, the popularity of the standard looks to continue unabated.

Is ISO 14001 missing something? Should it be changing at all? Join the conversation in the comments below, or via Twitter @TriplePundit.

Business needs to consider plastic footprint as much as carbon

Companies could become more sustainable by improving the way they measure, manage and report the amount of plastic they use in their business operations and supply chains, according to ground-breaking new research by the Plastic Disclosure Project, the UN Environment Programme and natural capital analysts Trucost.

The report, entitled Valuing plastic: the business case for measuring, managing and disclosing plastic use in the consumer goods industry, was published at the UN Environment Assembly in Nairobi, Kenya.

The research is the first-ever assessment of the environmental costs of plastic in business. It calculates the amount of plastic used by stock exchange listed companies in sixteen consumer goods sectors and assesses levels of corporate disclosure on plastic. Its aim is to help companies understand the risks and opportunities of plastic and build a business case for improving its management.

Trucost calculates the total natural capital cost of plastic in the consumer goods industry to be more than US$75 billion per year. The cost comes from a range of environmental impacts including the harm done by plastic litter to wildlife in the ocean and the loss of valuable resources when plastic waste is sent to landfill rather than being recycled.

Plastic use in the food sector has the largest impact in absolute terms, responsible for almost a quarter of the total natural capital cost. The toy sector has the largest natural capital intensity, as the natural capital cost of its plastic use is equivalent to 3.9% of its annual revenue.

The most significant downstream impact of plastic use by the consumer goods sector is marine pollution, which has a natural capital cost of at least $13bn. This is likely to be an underestimate due to the need for further scientific research, for example, on the impact of small particles of plastic known as microplastic. The most significant upstream impact is greenhouse gas emissions released from producing plastic feedstock, which is responsible for almost a third of the total natural capital cost.

The impacts of plastic vary around the world. Companies face higher natural capital costs if they purchase or dispose of plastic in Asia compared to North America, Europe or Oceania due to the higher pollution intensity of manufacturing in Asia and its lack of adequate waste management facilities.

At present, levels of disclosure are poor with only half of the 100 consumer goods companies assessed reporting at least one item of data on plastic use. Disclosure rates vary widely, with no companies in the athletic goods and footwear sectors reporting any usable data compared to almost 90% of firms in the durable household goods sector.

Andrew Russell, director of the Plastic Disclosure Project, commented: “The research unveils the need for companies to consider their plastic footprint just as they do for carbon, water and forestry. By measuring, managing and reporting plastic use and disposal through the PDP, companies can mitigate the risks, maximize the opportunities, and become more successful and sustainable businesses.”

Picture credit: © Jiri Vaclavek | Dreamstime.com

3p Weekend: 7 Companies That Make Employee Volunteering a Priority

With a busy week behind you and the weekend within reach, there’s no shame in taking things a bit easy on Friday afternoon. With this in mind, every Friday TriplePundit will give you a fun, easy read on a topic you care about. So, take a break from those endless email threads, and spend five minutes catching up on the latest trends in sustainability and business.

It's easy to start losing your faith in humanity once Friday rolls around. To give you a bit of a mental boost this afternoon, we rounded up seven industry-leading companies that make employee volunteering a priority while still turning a profit.

1. Timberland

Timberland is well known as a leader in the social good space, and the company recently surpassed 1 million employee volunteer hours served. This milestone has been in the making since the brand launched its Path of Service program in 1992.As part of this program, each Timberland employee is given up to 40 paid hours per year to dedicate to service. Timberland volunteers have initiated nearly 4,000 service projects in 32 countries since 2010, when project-specific metrics started being tracked, according to the company.

2. Patagonia

Not to be outdone by its fellow outdoor brand, Patagonia has become a frontrunner in employee giving in its own right. From an environmental internship program, to an annual 'bike-to-work week' and Salmon Run, the company offers an industry-leading assortment of ways for employees to get involved.

3. Boeing

Boeing offers one of the most comprehensive employee giving programs out there. Employees receive $250 grants for every 25 hours volunteered and $100 grants per fundraising walk, run or bike ride. All totaled, each employee can receive up to $6,000 in matching funds annually to donate to their charities of choice, as Triple Pundit reported in a 2012 series.4. Microsoft

Microsoft’s annual Employee Giving Campaign takes place in the U.S. throughout the year. A special push every October brings more than 300 activities to the company's corporate campus, including a 5K Run, an online auction and other special events.Microsoft also matches employee nonprofit donations and volunteering year round up to $15,000 per employee. Today, more than 39,000 employees participate in the campaign, which is approximately 65 percent of Microsoft’s total U.S. workforce, and employees have donated more than $1 billion, inclusive of the company's $1-to-$1 match, since the program began in 1983.

5. SAP

SAP partners with several different NGOs to spur employee volunteering in the United States. The company's signature volunteering initiative is its annual Month of Service held in October, where more than 150 projects are executed across the country.Thousands of SAP employees in the U.S. participate in the Month of Service, along with several partners and customers in some cities, according to the company. The company also matches up to $2,500 in charitable donations per employe, per year and offers hardware and software donations through a nonprofit partnership with Techsoup.

6. PwC

In a recent interview at the 2014 Sustainable Brands conference in San Diego, Clinton Moloney and Amy Longsworth of PwC said volunteering programs are at the heart of the consultancy's strategy for employee engagement and retention.In its most recent move to bolster employee engagement while doing social good, PwC made a $160 million commitment over five years to drive up volunteerism in the company. The program, called Earn Your Future, allows PwC employees to increase financial literacy in children and teens by creating lesson plans for students of all ages.

“What we’ve seen is the leaders of our 20-something offices compete on how many hours they can get volunteered to deliver the Earn Your Future program, so it’s actually a core success metric for our most senior partners,” Moloney told Triple Pundit.

7. Panera Bread

Social good is at the heart of Panera Bread's business model. Since launching its first pay-what-you-can Panera Cares Cafe back in 2010, the company has served up millions of meals to those in need.To get employees involved, the recently company rallied associates, managers and MyPanera members across the country at 12 different food banks to volunteer their time together for National Volunteer Month in April.

Based in Philadelphia, Mary Mazzoni is a senior editor at TriplePundit. She is also a freelance journalist who frequently writes about sustainability, corporate social responsibility and clean tech. Her work has appeared in the Philadelphia Daily News, the Huffington Post, Sustainable Brands, Earth911 and the Daily Meal. You can follow her on Twitter @mary_mazzoni.

Why Tim Cook's Leadership Won't Lead Apple to the Next Phase of CSR

Three years after taking over the leadership of Apple, Tim Cook is still struggling to make his own mark in the company. A profile article in the New York Times published last week described the challenges Cook faces while trying to lead a company, living in the shadow of Steve Jobs and “making Apple his own.”

According to the article, there are still many people -- including some of Apple’s shareholders -- wondering if Cook can fill Jobs’ shoes and maintain the company’s position as an innovation powerhouse and the most valuable company in the world.

One issue where Jobs’ shoes aren’t too big to fill is corporate social responsibility (CSR): In his day, Apple was famous for its reactive CSR strategy, low level of transparency, little commitment to stakeholder engagement and a generally dated approach to what responsibility in business means.

Cook -- who had to address some of the issues that were the result of Jobs’ approach, such as the working conditions at Foxconn -- seems to be more open-minded about CSR, promoting an agenda focusing on climate change, human rights and philanthropy.

The interesting question is whether this is enough to build Cook’s own legacy and make Apple not just his own, but also more sustainable? I believe the answer is no. And the reason is not what is in his agenda, but what is missing from it.

Right now, Cook’s approach puts him somewhere between what Prof. Michael Porter describes as the first and the second phases in the evolution of the role of business in society. Examples include philanthropy (Cook established a program to match employee charitable contributions) and good citizenship/sustainability (supporting proposed federal legislation protecting LGBT workers, using 100 percent renewable energy sources in Apple’s data centers, publishing an annual list of Apple’s major suppliers, and so on).

These are all important steps, and we definitely need more CEOs that are not afraid to tell shareholders to sell their stocks if they don’t like policies on issues like climate change. At the same time it’s too little given our sustainability challenges in general and Apple’s challenges in particular. At best it will put Apple and Cook in the middle of the pack, with little chance to become the new Paul Polman or help him build his own ethos.

So, what can Cook do? Here’s one idea he might want to consider: Forget about philanthropy and good citizenship/sustainability and start thinking about designing the new phase in corporate responsibility: The responsible economy.

It all starts with the fact that interestingly the biggest challenge Cook is facing now is also is the biggest opportunity has to make his mark. What we’re talking about? In one word: growth.

As the New York Times article describes many Apple investors “worry that it can’t continue to match the growth that brought it from $65 billion in sales in the 2010 fiscal year to $171 billion in 2013. In fiscal 2013, sales grew a mere 9 percent, far below an average just shy of 40 percent a year from 2004 to 2013.”

The problem Toni Sacconaghi, a financial analyst at Bernstein Research, explains is that Apple won’t be able to show this sort of phenomenal growth “unless it comes up with a gigantic hit on the order of the iPhone.”

Apple’s challenge in a way reflects some of the ills of our economic system, where companies are expected to show continuous growth and can’t really get off the growth treadmill or reduce their growth rate without being punished by the markets. The result many times is short-termism, or in other words making decisions that favor the next quarter over the next decade just to make investors happy.

So what can Cook do about it? He can try looking for the next hits, hoping that somehow he can win the law of large numbers time and again, or at least until his term is over and it becomes someone else’s problem. Yet, his chances are rather slim – as Sacconaghi explains in the article even if Apple sells 10 million units of iWatch in the first year, “it would add a mere 50 cents to its earnings per share, barely a single percentage point.”

The other option he has is to revolt against the system, and say NO to unreasonable growth expectations. Instead he can offer shareholders and stakeholders his own version of what Patagonia calls “The Responsible Economy,” i.e. “an economy that does not rely on insatiable consumerism as its engine, an economy that stops harmful practices and replaces them with either new, more efficient practices or older practices that worked just fine.”

I know it might sound a bit crazy – after all, Apple is not Patagonia, so the sort of discussions and questions about consumerism, responsibility in business and sustainability that might be a perfect fit for Patagonia just doesn’t work for Apple. But at the same time isn’t it crazier to believe that a company with $171 billion in sales will continue growing in double-digit figures forever and ever?

Well, I believe the opposite is true. Apple is actually very close to a point where these questions will become essential to its future. It will have to decide very soon if it continues to focus on growth and planned obsolescence or start thinking in terms of long-term economic stability, responsible design and sustainability.

Now, this doesn’t mean that Apple will stop being innovative or developing new ideas – it will just need to think differently about innovation. It will require leadership, determination and creativity and it won’t be easy, but it can also be a very rewarding process, eventually ensuring that Cook’s legacy will be beyond the next iGadget. So now it’s up to you, Tim!

Image credit: Mike Deerkoski, Flickr Creative Commons

Raz Godelnik is an Assistant Professor of Strategic Design and Management at Parsons The New School of Design. You can follow Raz on Twitter.

4 Lessons the Apparel Industry Can Learn from Carpet-Makers

The 2014 Sustainable Brands conference in San Diego prompted discussions about a host of sustainability issues, from climate resilience to consumer engagement. But in a nation where waste recovery rates have hovered below 35 percent for the past decade, it was tough not to talk about recycling as well.

In a panel discussion hosted by the Cradle to Cradle Products Innovation Institute, leaders in the textile recycling space spoke about lessons learned that can be applied to the apparel industry, which is a key area of focus for the institute. One of the more surprising additions to the panel, entitled “Optimizing Building Blocks: Cradle to Cradle Materials for Textiles," was Paul Murray, vice president of sustainability and environmental affairs at Shaw Industries, the world’s largest carpet manufacturer.

Believe it or not, there's actually a great deal the apparel industry can learn from carpet-makers about closed loop recycling. Shaw, for example, has been producing Cradle to Cradle certified products for more than a decade, and they now make up 64 percent of the company’s sales. I sat down with Murray after the panel to find out more about how the carpet industry's success with closed loop recycling can be applied to your favorite fashions and lessons that translate across the textile industry.

1. Design with the end use in mind

The most obvious aspects of closed loop recycling happen in the collection and re-processing phases, but Murray noted that the process starts much earlier -- in the design phase. When recovering textiles for recycling, it's vitally important that the material components are nontoxic, safe for recycling workers and safe for the end consumer.

"It was early that we looked at [closed loop] as a system to prevent bad chemistry," Shaw said, noting that the materials assessment for Cradle to Cradle certification is much tougher than EPA standards. "Federal law makes us disclose everything up to 1 percent; Cradle to Cradle makes you look at that chemistry down to 100 parts per million, or one thousandth of a percent. So, it's 1,000 times stronger than the EPA would require of an apparel industry, but it makes things a lot safer for the general public."

Materials assessments look at everything from dyes and glues to the fabric itself. Beyond ensuring products are nontoxic, nuts-and-bolts design decisions, such as the construction of the product, also play a key role in making sure the product can be re-purposed at end-of-life.

"We want to make sure that those materials have a second life," Murray said of Shaw's carpeting. "So, we actually try to then manufacture the products so that they can come apart in one shape or form or another.

"The apparel industry has several issues that we have to deal with in a different way. One is how do you take a piece of, let's say, jeans and get the rivets and the zipper out so that the fabric could actually be used."

2. Take a branding approach to closed loop

Achieving Cradle to Cradle certification for a product is no easy feat, but that's only the beginning, Murray explained. To make a closed loop product successful, he said, companies need to make their customers aware of its value. To achieve this, he suggested a branding approach with which most companies are already familiar.

"Cradle to cradle is a concept, a process and a label," Murray said. "If nobody knows about that label, then you don't have brand recognition. People won't look for [the Cradle to Cradle certified label] on a piece of carpet if they don't know about it. So that's what I would call 'brand recognition' for the certification itself.

"As the apparel industry looks to cradle to cradle as a solution, they need to be thinking about what they [can] do to help that brand recognition," he continued. "How do we get to that partnership of building the Cradle to Cradle brand? I think it's important for all cradle to cradle companies to work together for that branding."

A select few apparel companies, such as Puma, have already started to build branding around their Cradle to Cradle certified products, while others, like Levi Strauss & Co., focus on branding around recycling through their own processes. But most would agree there's still much more to be done in this area.

3. Never stop looking for new technologies

When we spoke with global, end‐to‐end textile solutions provider I:CO last month, Jennifer Gilbert, the company's chief marketing officer, likened fabric recycling to paper in the sense that fibers shorten and degrade when they are recycled. Although the company has managed to devise end uses for several textile categories, Gilbert noted that the degradation of fabric fibers poses significant challenges, and she's right -- at least for now.

With most processes used today, recycled textiles must be combined with virgin feedstocks to compensate for fiber shortening, but cutting-edge techniques are under development across the country, Murray noted. Shaw, for example, uses a high-tech depolymerization process to turn grimy used carpeting into a brand new product. Since fibers are broken down at the polymer level, the result is essentially new fiber that is just as strong -- if not stronger -- than the original tossed carpeting.

"I think the technology will really change over time," Murray predicted, pointing to a fledgling effort in Seattle that devised a process to grind cotton so fine it can be extruded as new fiber -- much like the process used to make rayon back in the 1980s.

"There's going to be a lot of different developments in all sectors, whether it be carpet or apparel," he continued. "Even the carpet industry today: When you look at a piece of carpet it's glued together. The methodology to take that apart, we continually work on. So, that's an example of an industry where we have to work collaboratively to come up with methods to take things back."

Staying open to new technologies and supporting them financially when possible is key to moving the closed loop process forward, Murray said. Shaw, for example, partners with roughly 50 entrepreneurial recyclers across the country to recover its carpeting, while I:CO works with literally hundreds of partners from around the world to develop new recovery processes.

4. Be patient with infrastructure

"Everybody that talks about cradle to cradle makes this point: It really has to start somewhere," Murray said.

It's true that the infrastructure for textile recovery is growing, and companies like I:CO are a big part of that, but it can be easy for brands to become frustrated with the lack of take-back options or end uses for their products. This frustration, however, is no reason for companies not to pursue closed loop options and think about them in design.

"You really don't start with the infrastructure to take things back," Murray said. "You start with making sure that what you're producing is as safe and environmentally friendly as possible ... That's really where the apparel industry has to get strong."

As methods evolve for producing products that are safer to recycle and reuse, as well as for the re-processing itself, the infrastructure will slowly start to catch up -- especially if consumers are engaged and asking for closed loop products, Murray said.

To engage its own consumers, Shaw recently sent out the below video to its online mailing list, which details how Shaw uses closed loop processes and efficiently sums up the five basic tenants of Closed Loop certification.

Image credit: Flickr/bluehillranch

How Food Waste Recovery Fills Pockets Instead of Landfills

Human beings are very clever -- clever enough to remake much of the world in the image of what lies in our collective imagination. We are also clever enough to forget, perhaps for generations, that we are still a part of nature. But part of our cleverness also involves learning from our mistakes.

People are beginning to wake up to the fact that even our wildest excursions of creativity and talent must be grounded in and informed by the lessons of nature. Nature, being the ultimate master of the subject, can teach us how to survive. Nature wastes nothing. The very idea of waste does not exist in nature. Leaves fall from trees and decompose, turning back into food for the trees and the millions of organisms employed in that industry.

People recycle, too. Aluminum cans become car frames or more cans. Yesterday’s front page becomes tomorrow’s sports section. We are saving lots of energy and resources in the process and feeding those employed in that industry. But food waste, despite the tremendous biochemical value contained within it, has been slow to follow. Food is wet and sloppy. It smells bad, and it rots -- providing a potential haven for microbial bad guys. It must be picked up and disposed of promptly, and unlike aluminum or paper, it contains a lot of water, which makes it heavy.

So, other than the few of us who compost, most of the food waste goes into the landfill. According to the EPA, close to 50 percent of what goes into landfills is organic material. Some of that is recovered as landfill gas, but we could do much better, especially considering that a great deal of that methane, a dangerously potent greenhouse gas, escapes into the atmosphere. But, beyond avoiding methane release, there is tremendous value that can be recouped from this material.

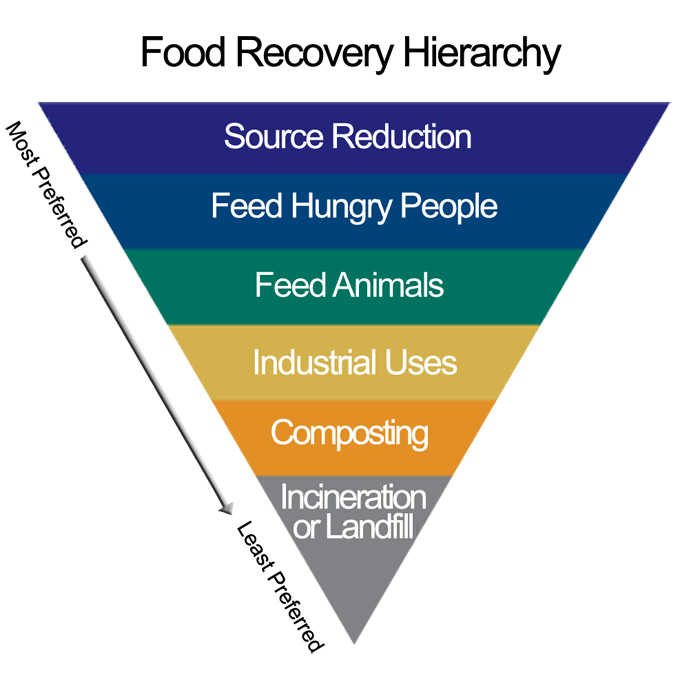

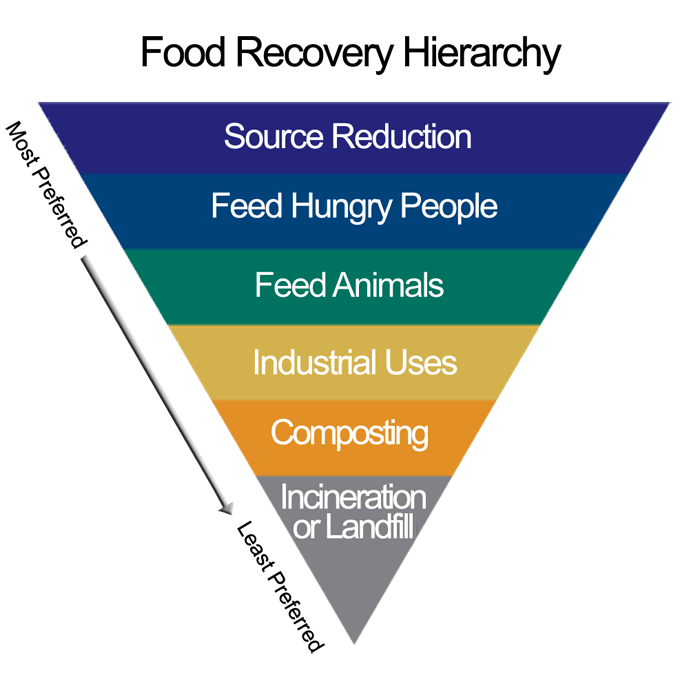

The EPA has developed a food recovery hierarchy that provides guidelines for extracting the maximum value from food waste. The suggested hierarchy, going from most preferred to least preferred is:

- Source reduction (don’t create the waste in the first place)

- Feed hungry people (donate excess usable food to the hungry and homeless)

- Feed animals

- Industrial uses

- Produce compost

- Incinerate or landfill

As you can see, the hierarchy is arranged in order of the amount of value that can be extracted. Another great source of information on this subject is the Food Waste Reduction Alliance who just published a toolkit for those ready to start their own food recovery operation.

A number of companies are currently in the business of food recovery:

- Turning Earth takes in food and yard waste and then processes it in an anaerobic digester, producing biogas. Solid material is converted into compost. Waste heat from both the anaerobic digester and the composting operation is used to keep greenhouses warm during the winter, providing year-round food production, which in turn produces more waste that can be fed back into the system.

- Missouri Organic has a program they call Food Residual Environmental Diversion (FRED) that turns food waste into compost, keeping it out of landfills. Last year, they successfully diverted 32 million pounds of organic material.

- Quest Recycling starts from the waste management portion of the cycle. They provide a variety of waste recovery services including working with restaurants and hotels to recover value from food waste. In 2012, they recovered over 850 million pounds of food waste, which was converted into bio-diesel, animal feed, and other alternative fuels.

Considering the value creation potential here, it’s clear that the surface is only just being scratched. Consider Fiberight of Catonsville, Md. They are a waste disposal/energy company that uses compressed natural gas generated from the collected municipal solid waste to power their trash haulers. They also convert fibrous materials such as cardboard and packaging material and convert them into cellulosic ethanol. At the end of their process, 80 to 85 percent of everything they collect is put to use, thereby avoiding the landfill. The company is currently expanding into two large scale facilities in Iowa.

As good as that is, technology demonstrated by Epiphergy, in Rochester, N.Y., can utilize better than 99 percent of all the food waste they collect. A single process takes in all the waste and in five days, after a certain amount of pumping, mixing and incubating with a proprietary mixture of what founder Graham Fennie calls “herbs and spices,” converts it into a liquid from which both ethanol and a highly nutritious animal feed can be produced. The residual solid material is converted into organic compost. Fennie, who has several patents pending on the process, calls it “upcycling waste.” He is currently looking for partners to help scale up the process.

If you think about it, these guys are acting as manufacturers, with the notable difference that instead of buying their raw materials, or growing them, or extracting them from the Earth, they are being paid to take them by people who want to get rid of them.

These are potentially disruptive changes, and they will take time for our society to get its collective head around. But as we continue the journey towards a sustainable economy, we find that there is really no facet of our world that cannot benefit by following the lessons being taught every day by nature.

Image credit: Epiphergy animal feed from food waste by RP Siegel; Graph courtesy of EPA

RP Siegel, PE, is an author, inventor and consultant. He has written for numerous publications ranging from Huffington Post to Mechanical Engineering. He and Roger Saillant co-wrote the eco-thriller Vapor Trails. RP sees it as his mission to help articulate and clarify the problems and challenges confronting our planet at this time, as well as the steadily emerging list of proposed solutions. His uniquely combined engineering and humanities background help to bring both global perspective and analytical detail to bear on the questions at hand. Follow RP Siegel on Twitter.

EVs and the Emerging Solar-Powered Energy Ecosystem

Editor's note: This is the second post in a two-part series on building a national fleet of electric vehicle charging stations. In case you missed it, you can read the first post here.

With SolarCity and Tesla, Elon Musk and team have crafted a template for a triple bottom line business that melds the production of solar electricity and its use in transportation, residential, commercial and industrial settings. Tesla's Supercharger fleet of electric vehicle charging stations is a key facet of this vertically integrated, solar-powered energy “ecosystem.”

As 3p reported in part one of this series, Tesla isn't the only one looking to build out a nationwide fleet of EV charging stations. Miami's Car Charging Group, Inc. is working to assimilate and revive the EV charging station assets it acquired during a recent string of acquisitions. Furthermore, a recent executive hire points out the longer term direction the company may be heading, one that could capitalize on the same sort of business symbiosis inherent in the Solar City-Tesla combination.

A nationwide EV charging network: A historical parallel

Mutual interest brought oil company majors, U.S. auto manufacturers and the federal government together to produce the fuels and build the roads, highways and vehicles that have come to define American life in the post-World War II era. Oil companies produced the gasoline and diesel cars and trucks needed, and they seized the opportunity to integrate vertically and control the supply of petroleum fuels from wellhead to vehicle owner.

The largest, most successful commercial enterprises of the era, the oil industry's “Seven Sisters,” bankrolled and built out a nationwide network of gasoline and diesel filling stations over the first half of the 20th century. To date, no large industry backer – electric utility or otherwise – has fully committed to doing so for EVs. That has left the field largely open to ambitious entrepreneurs and start-ups.

That said, there has been some interest among EV manufacturers -- which at this point includes nearly all the world's multinational auto manufacturers -- and it's growing. In May 2013, Nissan, the manufacturer of the Leaf EV, partnered with Car Charging Group to build out 48 fast-charge DC EV stations in California and “strategic places on the East Coast.”

Just this past week, news broke that Tesla, Nissan and BMW are talking about collaborating to develop standards for EV car charging and technology.

The reincarnation of EVs

In 1908, at the dawn of the petroleum era, some 28 percent of automobiles in the U.S. were powered by electricity. This initial generation of EVs was almost completely eradicated with the advent of abundant supplies of crude oil and refined petroleum products, the advent – with Mr. Ford – of scientific research-driven mass production methods and technology, and the business tactics of the Standard Oil companies.

Today, EVs represent less than 1 percent of U.S. auto sales. The beginnings of a resurgence is apparent, however. Extensive networks of charging stations will have to be built if EVs and the vision of a clean, renewable and distributed energy infrastructure is to truly take root and clean, renewable electricity become the predominant form of energy for transportation, as well as residential, commercial and industrial use.

The challenges faced by budding EV infrastructure players such as CarCharging Group and Tesla are similar to those faced by the oil majors a century ago when they undertook the challenge of building out gasoline and diesel filling stations, as well as those faced today by wind and solar power developers.

Innovative, opportunistic businesses gravitated toward and built out from local and state markets where government and public support were highest. At first, markets were small and fragmented. Businesses failed, some amid public scandal. Nonetheless, a nationwide network eventually emerged.

Faced with similar challenges, CarCharging is at present focused on integrating and reviving the EV charging station assets and business of the four acquisitions it made over the course of 2013.

Management also seems to be casting an eye further out on into the future. The recent hire of David Cohen as Chief Strategy Officer may point the strategic direction CarCharging sees itself heading.

Of EVs and solar microgrids

In a recent presentation given at a solar/distributed energy technology conference in New York City, Cohen reviewed the progress being made around the U.S. with regard to development and management of solar microgrids. He also went into some detail regarding the technical aspects of these local scale, solar-powered microgrids, and how EV charging fleets fit into an overall clean energy ecosystem.

Drawing load when charging, a large population of EVs poses problems for electricity grids and their operators. R&D to reverse the flow of electricity and make it bi-directional – electric vehicles supplying, as well as drawing, energy from the grid – is underway. Dubbed "EV2Grid," the concept has yet to be proven at commercial scale.

Cohen's expertise lies in developing software and systems that can balance electricity supply and demand in an intelligent way, integrating solar PV and hybrid generation assets with energy storage solutions and EV charging stations, as well as smart grid demand response (DR) and automated metering infrastructure (AMI). The result is a localized and distributed, yet vertically integrated, clean energy ecosystem.

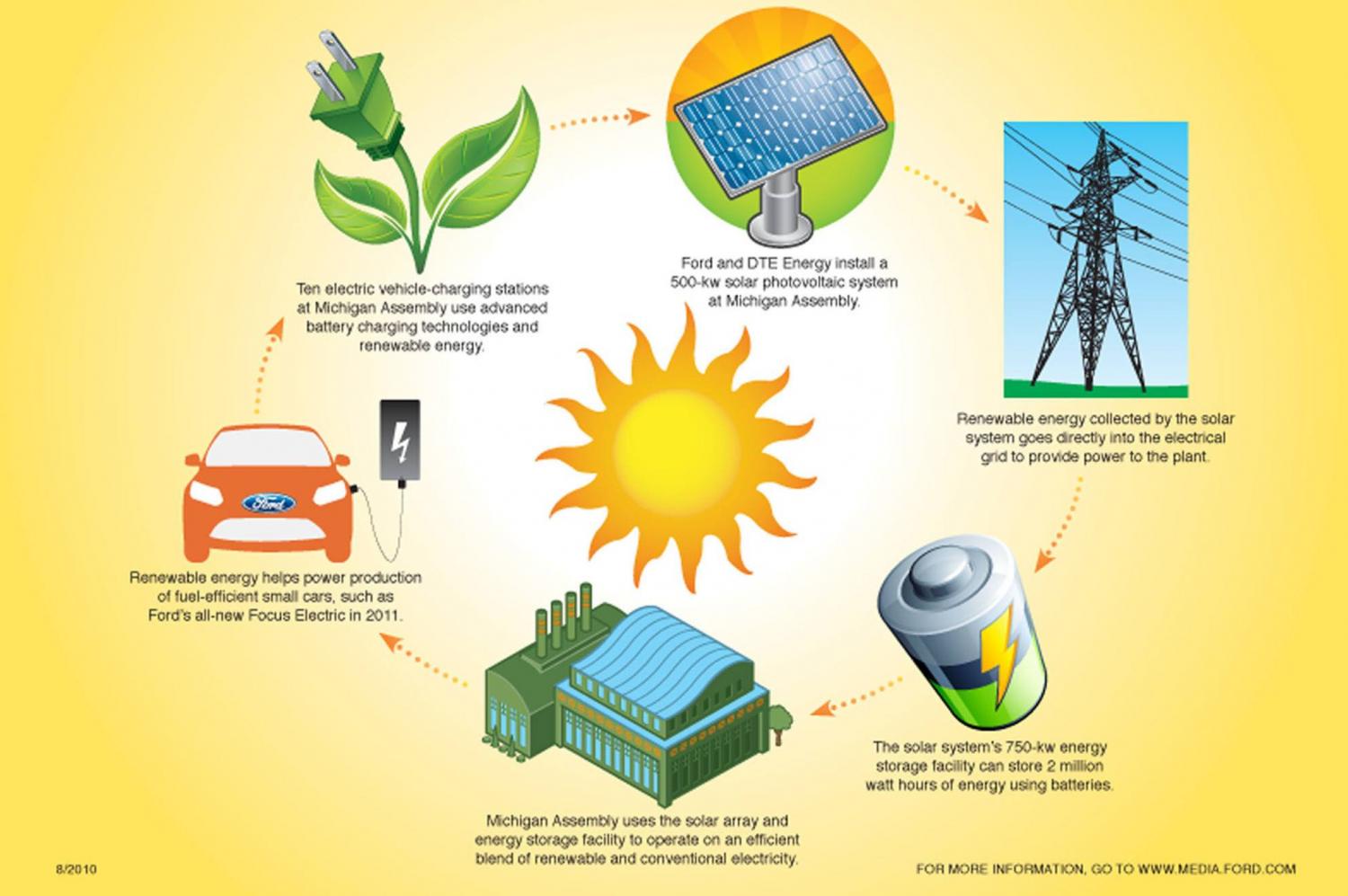

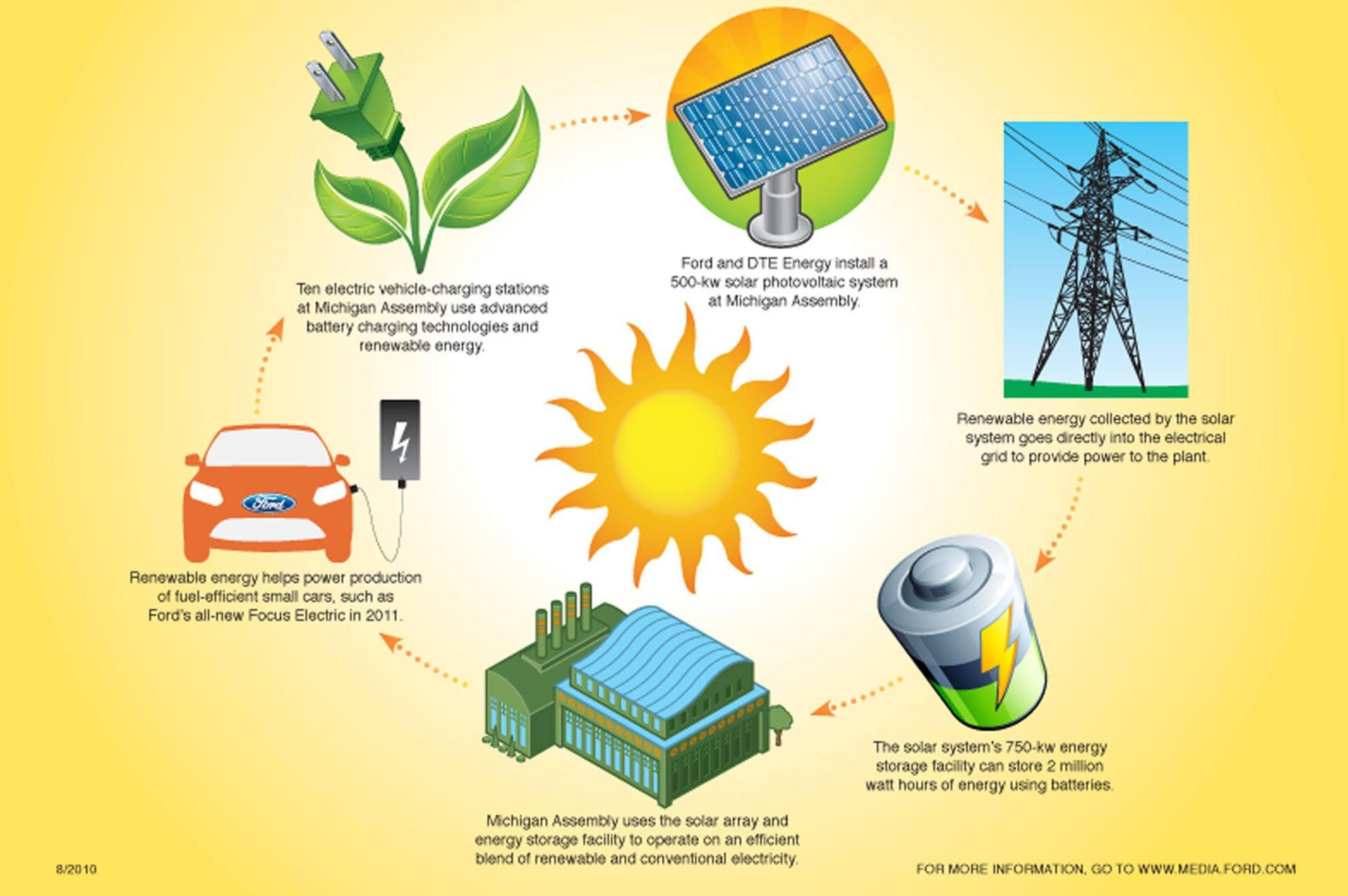

Ford has incorporated solar PV arrays and EV charging stations into a microgrids that supplies electricity to one of its auto manufacturing facilities in much smarter, cleaner, more efficient fashion. What may be the biggest solar-hybrid energy microgrid in the U.S. has been up and running at the University of California San Diego for two years.

Cohen and other microgrid experts' vision of distributed solar and hybrid energy microgrids parallels the path the oil majors took in diversifying and integrating supplemental technology, products, services and business lines. Theirs differs in a big, fundamental way, however: Rather than extracting oil, coal and natural gas from deep beneath the earth's surface, they envision electricity produced from renewable energy sources as the fuel for both power generation and transportation.

Making such a vision reality would enable the U.S., and possibly many other countries, realize huge reductions in greenhouse gas emissions in a short period of time. That, in turn, would significantly reduce the economic, social and ecosystems threats and costs posed by ongoing increases in fossil fuel production and use.

To top things off, building out, operating and maintaining solar and hybrid renewable energy microgrids -- along with EVs, EV charging stations and energy storage systems -- could power the U.S. economy well into, if not throughout, the 21st century.

Image credits: 1) Avinash Kaushik from Flickr; 2) & 3) Ford; 4) GTM Research

Ultra-Energy Efficient Homes: Are They Worth the Upfront Cost?

When building a new home, design and material selection greatly impact the operating costs for decades. Investing in triple-pane windows and doors, generous insulation, and air sealing can greatly reduce your heating and cooling costs, while also boosting comfort. Is it financially savvy to construct a super efficient home over a code-built home because of the reduction in operating costs?

The simple answer is yes, but the more detailed answer is that it depends. Some energy efficient upgrades have a lot of bang for your buck, while others don’t. Your local climate is another variable.

Tessa Smith, co-owner of the Artisan Group in Olympia, Washington says the payback period of upgrading a home to an ultra-energy-efficient home over a code-built house can be a mere five years or less in the Pacific Northwest, with the upfront construction costs being four to six percent higher. Super-efficient homes require an investment in different materials and mechanical systems, some increasing and others decreasing the construction costs. Mechanical ventilation, more efficient hot water heating, upgraded windows and doors, and more insulation add to the cost, while money is saved on the heating and cooling system, according to Smith.

Super efficient homes with air sealing require mechanical ventilation to circulate outside air, bringing in a fresh stream of filtered air and preventing mold issues. Such homes typically don’t use combustion fuels, such as natural gas furnaces and propane stoves, because the byproducts contaminate the indoor air quality. Airtight homes with air sealing allow very little air into the home, thus fresh air is brought in with a ventilation system that recycles heat.

All 36 homes at Belfast Cohousing & Ecovillage (BCE) in Midcoast Maine have Zehnder heat recovery ventilation (HRV) systems, that transfer 90 percent of the heat from the exhaust air to the intake air before it exits the home. Stale air is removed from the kitchen and bathrooms and fresh air is supplied to the bedrooms.

“Air sealing a building prevents the air you have paid to condition from leaving the building -- but it also prevents air that may be filled with contaminants from entering uncontrollably,” says Adam Romano, Director of Training Operations at the Association for Energy Affordability. “Combining air sealing with proper ventilation, such as Heat Recovery or Enthalpy Recovery Ventilation systems (HRV/ERV) will provide control over where you extract the contaminants produced in your home, how you treat incoming air to remove external contaminants, and how you optimally distribute this fresh air into living spaces.”

Although a high-efficiency HRV system for a house may cost more than exhaust-only ventilation, it is a necessary fixture in high efficiency homes and reduces the operating costs by allowing a higher level of energy efficiency that would otherwise result in poor indoor air quality and moisture issues without mechanical ventilation. A typical code-built house exchanges air into and out of the home through leaks, exhaust fans and mechanical systems, although this is very inefficient when it is cold outside because the heat isn’t captured before leaving the home. The HRV system helps make it possible to remove a much costlier and less efficient furnace or boiler by very efficiently heating intake air with recycled heat from the exhaust air.

“These houses [at BCE] are so tight that you can control what air comes in through one little pipe,” explains Brian Hughes, a carpenter for GO Logic and member of BCE. “Then you can use a heat exchanger to take almost all the energy out of the exhaust air [before it exits the home].”

Many high efficiency homes have no boiler, furnace, or air conditioners, as simple electric baseboard heaters can sufficiently and economically heat the home. The heat loss of the home is modest, even in a cold climate like Maine. “Because the heat loads of the buildings [at BCE] are so low, it really doesn’t argue for anything but the cheapest heating system you can get, which is electric resistance baseboard heat,” says Alan Gibson, principal of GO Logic, the design-build company that worked with BCE members to design and construct the community. “We saved a lot of money there.”

Gibson estimates that replacing the heating system with electric baseboard heaters saves $15,000 in the 1,500-square-foot homes. Other energy-efficiency components boost the construction costs, including air sealing, a high-efficiency heat recovery ventilation system, improved insulation, and triple-pane windows and doors. The result is a 7 percent increase in construction costs, with a seven and a half year payback period from the energy savings.

These energy efficiency upgrades result in a 90 percent reduction in energy for space heating compared to the average house, yielding much lower heating bills. Gibson estimates a 1,500-square-foot BCE home uses $300 to heat using electric baseboard heat, while a standard Maine home costs over $2,500 to heat with an estimated 680 gallons of oil. In addition, the homes stay cool in the summer without needing air conditioning. If these ultra-efficient homes are purchased using a mortgage, it results in lower annual bills (a higher mortgage offset by lower electric bill), thus having an instant payback.

“Increasing building performance has a multitude of benefits,” adds Romano. “The associated fuel savings and lower operating costs, are obvious; others take a little longer to show themselves, but can be more dramatic. What value would you put on decreasing the frequency or intensity of your child's asthma attacks, reducing hospitalizations and missed school days? Direct health benefits flow from increasing your home's energy efficiency, many resulting from improved indoor air quality.”

Image credit: GO Logic (upper photo) and Belfast Cohousing & Ecovillage (lower photo)

Sarah Lozanova is a regular contributor to environmental and energy publications and websites, including Mother Earth Living, Green Building & Design, Triple Pundit, Urban Farm, and Solar Today. Her experience includes work with small-scale solar energy installations and utility-scale wind farms. She earned an MBA in sustainable management from the Presidio Graduate School and she resides in Belfast Cohousing & Ecovillage in Midcoast Maine with her husband and two children.

Ohio Stalls Green Energy Projects

Ohio Gov. John Kasich took what clean energy proponents deemed retrograde executive action last week, putting the brakes on Ohio's clean energy drive.

In 2008, Gov. Kasich signed Ohio's Renewable Portfolio Standard (RPS) into law, requiring utilities by 2025 to obtain 25 percent of their electricity from alternative energy resources, and at least 12.5 percent from renewable energy resources. On Friday June 13, Kasich enacted Ohio Senate Bill 310 (SB 310), which freezes renewable and energy efficiency drive for two years.

Gov. Kasich and the Ohio state legislature followed that up by “abandoning $2.5 billion in wind energy projects,” according to the American Wind Energy Association (AWEA). This past Monday, June 16, Ohio's governor signed House Bill 483 “without vetoing a last-minute insertion that requires wind turbines to be at least 1,300 feet from the nearest property line instead of the nearest house,” AWEA explains in a news release.

Ohio's clean energy double-whammy

Passage of HB 483, the state budget bill, effectively puts a stop to development of some $2.5 billion worth of wind power projects in Ohio, which has more in the way of wind energy manufacturing facilities (over 60) than any other U.S. state. Furthermore, AWEA highlights,

HB 283 was passed without “the regulators at the Ohio Power Siting Board, nor a single wind company operating in Ohio” given the opportunity to comment or provide testimony regarding the issue, which made its way through the state's General Assembly in just one week.

Meanwhile, passage of SB 310 makes Ohio the first state to renege on its RPS. As a result, Ohio's renewable energy mandate will remain at 2.5 percent and its energy efficiency standard at 4.2 percent compared to 2009 levels for the next two years.

Strong opposition to SB 310 was voiced from a variety of interest groups -- large manufacturers as well scientists and those doing business in Ohio's growing renewable energy and energy efficiency sectors, according to a report from Columbus Business First.

“Proponents say the market has changed since the bill was signe and that they aren't killing renewable standards, but simply want to study them,” Columbus Business First reporter Tom Knox writes.

Rather odd timing

The freeze comes at an inopportune time. Critics point out that it will make it all the more difficult for Ohio to meet the Obama administration EPA's proposed Clean Power Plan, which was published in the Federal Register on Wednesday.

Passage of HB 483, the state's budget bill, compounds the losses expected as a result of freezing Ohio's RPS. With its passage, Ohio is abandoning “$2.5 billion in current wind energy projects, which now face cancellation along with jobs, leases, payments to local governments, and orders for factories, over a needlessly restrictive setback requirement that Kasich signed into law,” the AWEA says. Elaborated AWEA CEO Tom Kiernan:

“Gov. Kasich has walked away from his commitment to renewable energy. He and the legislature are creating an unfriendly business environment in Ohio."Legislators rammed through restrictive rules without due process, and millions of dollars already invested based on the previous set of rules may now be lost without any public debate. This will force clean energy developers and manufacturers to move to neighboring states with similar resources and friendlier business climates.”

Furthermore, AWEA points out that Ohio's previous wind turbine siting requirements were among the most restrictive in the nation. The change from 1,300 feet from the nearest house to the nearest property line was “added to the state budget bill only after all public debate had already ended,” AWEA notes.

“If fully developed, the current projects could have provided approximately $220 million in local tax payments and $180 million worth of leases to landowners over the projects' lifetimes. With stable policies, those numbers could have steadily grown in the coming years,” the AWEA asserts.

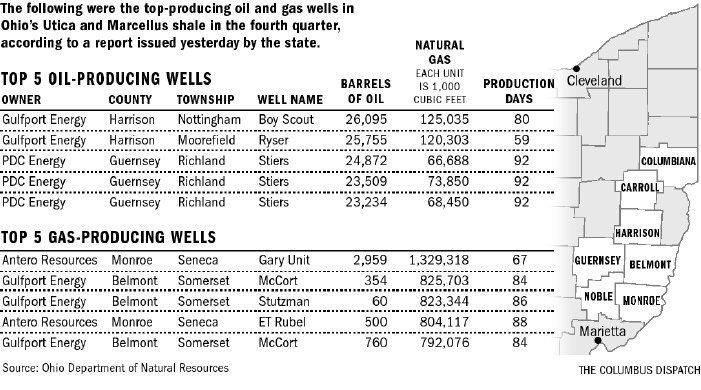

What prompted the abrupt and sudden political reversal of fortune? Difficult to say. Coal has played a big role in Ohio's economy. More recently, hydraulic fracturing ("fracking") of the Utica and Marcellus shale for oil and gas has been expanding rapidly along with a coincident rise in earthquakes and concerns regarding water contamination and use. Renewable energy appears on the outs, but “Drill, baby, drill” is alive and well in Ohio.

Images credit: 1) Cleveland.com; 2) AWEA; 3) Columbus Dispatch

New Solar Tariff on China May Slow Recent U.S. Solar Boom

The U.S. solar energy market has been booming for several years, due to falling solar component prices and stable government incentives. In an effort to boost domestic manufacturing, the Commerce Department recently ruled in favor of the petitioner SolarWorld, the largest U.S. solar producer for 40 years, to impose a solar tariff for Chinese solar products that may boost overall solar installation costs by an estimated 10 percent.

The new solar tariff on China may slow the recent U.S. solar boom. A preliminary duty of 35 percent on imports of Suntech, 19 percent on imports of Trina Solar, and 27 percent for most other Chinese solar producers are effective immediately. The ruling closes what SolarWorld calls a loophole in the solar tariff, where Chinese solar manufacturers used Taiwanese solar cells in Chinese solar panels to circumvent the solar tariff.

"Chinese producers evaded the duties by commissioning manufacturers in other countries to partially or fully produce solar photovoltaic cells for assembly into solar panels back in China" SolarWorld said in a recent press release. "State-controlled Chinese media said at least 70 percent of U.S. imports from China contain Taiwanese cells." SolarWorld’s petition states that Chinese solar manufacturers receive government assistance, including free land and utilities, cash grants, discounted loans and loan guarantees, and heavily discounted polysilicon, solar glass and aluminum.

Proponents of the tariff say that China is dumping solar components in the U.S., thus hurting U.S. manufacturing jobs in the process. The market will naturally favor low-cost manufacturing hubs, where wages and poor working conditions reduce costs. The tariff will level the solar manufacturing playing field.

Opponents fear the tariff will increase the price of solar panels by 20 to 40 percent, harming the solar industry that now employs 150,000 Americans. Brad Meikle believes the U.S. will never be a solar manufacturing hub, but that the economic opportunity lies in the installation, finance and distribution.

The recent solar boom, in fact, has been in large part due to a 70 percent drop in solar module cost. Boosting the module costs, either through a tariff on Chinese panels or encouraging more costly domestic panels is likely to decrease installations.

"The cost of solar energy has finally reached very attracted price levels of less than $3 watt installed,"said Kiril Lozanov, vice president of Capital City Renewables. "Increasing the price of the panels will not benefit the future growth of the industry."

The American Solar Energy Association (SEIA) is even calling for a negotiated settlement and expresses concern about the recent ruling. "Today’s decision by the U.S. Department of Commerce to impose new tariffs on solar modules from China threatens to derail the rapid growth of the U.S. solar industry."

SEIA President Rhone Resch said: "These damaging tariffs will increase costs for U.S. solar consumers and, in turn, slow the adoption of solar within the United States. Ironically, the tariffs may provide little to no direct benefit to the sole petitioner SolarWorld, as we saw in the 2012 investigations. It’s time to end this needless litigation with a negotiated solution that addresses SolarWorld’s trade allegations while ensuring the continued growth of the U.S. solar market."

The short-term impact of the ruling is already being felt. "The tariff has created fluctuation and uncertainty in the prices of solar panels and this is affecting me as a solar installer," says Lozanov. "I’ll give a bid for a solar installation to a client, and week later the panels are not available or the price has already increased."

The situation brings important issues to the surface. What is the role of government to offset market distortion effects? Are Chinese solar subsidies (called dumping by some) having a net positive effect on U.S. solar job creation, despite the potentially negative impact on U.S. manufacturers? In the interest of mitigating climate change, is the solar tariff counterproductive to reducing carbon emissions?

Image credit: WorldSolar

Sarah Lozanova is a regular contributor to environmental and energy publications and websites, including Mother Earth Living, Green Building & Design, Triple Pundit, Urban Farm, and Solar Today. Her experience includes work with small-scale solar energy installations and utility-scale wind farms. She earned an MBA in sustainable management from the Presidio Graduate School and she resides in Belfast Ecovillage in Midcoast Maine with her husband and two children.