Campaign Calls for 100 Companies, 100 Percent Renewable Power

A consortium of leading climate change nonprofits and multinational businesses have joined to launch an initiative that aims to see 100 of the world's largest companies power their businesses solely from renewable energy resources by 2020. Led by the Climate Group, the campaign -- dubbed RE100 -- counts Ikea, Swiss Re, BT, Commerzbank, Formula E, H&M, Mars, Nestlé, Philips, Reed Elsevier and J. Safra among its founding business members. The Carbon Disclosure Project (CDP) and the International Renewable Energy Agency (IRENA) also are working with the Climate Group to see the RE100 through to fruition.

Launched Sept. 22 during Climate Week NYC, the RE100 campaign aims to lead by example. It will serve as a showcase that highlights the economic, social and environmental benefits businesses can realize by going 100 percent renewable -- and just how leading businesses are moving towards the goal of 100 percent renewable power. It will also assist companies looking to make the switch from fossil fuel to renewable energy sources, including “providing guidance as to selecting and implementing the best approach to utilizing renewable power, and information on the financial implications, risks and rewards of different options.”

“We are delighted with the ambition of leading companies to go 100 percent renewable,” Ben Ferrari, director of partnerships for the Climate Group, was quoted in a news release. “We plan to continue to grow this group and expand our outreach in China and India over the coming year. It is an exciting time for renewable power.”

Tackling climate change via clean energy

RE100 member Ikea has already generated 1,425 gigawatt-hours of clean, renewable energy. The company intends to invest some 1.5 billion euros (~$1.95 billion) more in new renewable energy projects to meet the 100 percent renewable power goal by 2020.

“Investing in renewable power makes complete business sense. It aligns with our corporate expectations on financial returns and our values. So far, we have generated 1,425 GWh of power from renewable sources. We plan to invest approximately €1.5 billion in new renewable energy projects to meet 100 percent goal by 2020 goal – and RE100 is a great way to tell our story.”

Jurg Trub, head of environmental and commodity markets at Swiss Re, added that the global insurance/re-insurance company views tackling climate change while meeting the energy needs of a growing and developing world as an urgent matter.

“This can only be done by improving energy efficiency and switching to low-carbon options including renewable energy sources. Therefore by showing leadership in investing in renewable energy we are supporting this drive towards a low carbon future and we can also take advantage of the growing market that exists with these climate change solutions.”

Mainstreaming carbon accounting and reporting

Carbon accounting, reporting and disclosure are integral -- and prerequisites -- to crafting and carrying out effective greenhouse gas emissions reduction and energy efficiency plans. That's where CDP's particular expertise comes in. “We know that defining and reporting on corporate renewable energy commitments is critical to ensuring the development of authentic renewable energy and avoid double counting,” Pedro Faria, CDP Technical Director, was quoted as saying.

“We are committed to working with the Climate Group and other NGOs working on this same issue to provide clear and consistent guidance for companies. This will ensure credible and transparent reporting of company commitments.”

Images courtesy of the Climate Group

Greenpeace India: Tea Leaves Show DDT Pesticide Residue

Tea is a $2 billion industry in India, which is the fourth-largest producer in the world of the sought-after beverage. The rich, fragrant chai is also unquestionably a domestic market-driver, since more than 80 percent of the product grown in India is sold at home. So when Greenpeace recently released a report stating that tested samples of India’s most prolific brands had traces of pesticides – including the banned substance DDT – well, you can imagine it wasn’t an easy swallow.

The India Tea Board immediately released a statement that all samples met India’s stipulated limits of pesticides and were within safety parameters. With equally rapid speed, Crop Care Federation, which represents the country's agricultural-chemical industry, demanded a retraction -- asserting that Greenpeace had made up the numbers. Within days, Crop Care launched a suit against Greenpeace, stating that the environmental organization had refused to share data with outside sources.

“Greenpeace’s effort to keep essential data away from Indian experts is a clear indication that the report is not just unscientific and fabricated but also done with malicious intent to harm Indian economy at the behest of its foreign donors,” said Crop Care Chair Rajjul Shroff.

This statement piqued our interest. Why would Greenpeace do the extensive research it boasted, and yet refuse to share data with outside sources?

The fact is, it did share the data, said Neha Saigal, senior campaigner for Greenpeace India’s sustainability campaign.

“Currently we are in conversations with all tea companies and they have been positively engaging with us.” According to Saigal, in addition to publishing the stats it found, Greenpeace shared the information with each company in an effort to open dialogue about other ways to manage crops and reduce pesticide use in general.

“We have had commitments from Unilever and Girnar who [have] taken the first step in supporting and investing in pilots to create a roadmap to eliminate pesticides.” Saigal said the NGO has also engaged Tata Global Beverages, which hasn’t yet committed to removing all pesticides from its crop management plan. Greenpeace is attempting to reach out to companies on a one-on-one basis, and the approach seems to be working, Saigal said.

With China, Kenya and Sri Lanka gaining prominence in the tea market, tea producers in India have been under pressure to increase production and regain its once-envied No. 1 spot in the global picture. This has increased the focus on pesticides and also prompted a closer look at safe pesticide management by the Tea Board. Meanwhile, Greenpeace has been sounding a cautionary note -- a measure not always appreciated by the agrochem industry.

“Greenpeace India has been campaigning to move the current paradigm of agriculture away from an industrial and chemical intensive model towards ecological farming practices," said Saigal, who noted that tea isn’t the only industry that is under pressure to expand its size of the market. “The main elements to the current agricultural model include chemical fertilisers, [genetically-modified] seeds and chemical pesticides. We currently have campaigns to move government policy away from chemical fertilisers and the environmental release of GMOs.”

She says the NGO’s reticence to share its data with agrochem experts isn’t a reflection of secretive interests, but rather a question of appropriateness when it comes to the data that belongs to tea producers.

"[This] is for the tea companies to decide whether they want to share their data with a third party,” Saigal said. “The Crop Care Federation of India has no relation to the tea companies. Logically there is no reason for CCFI to send legal notices to Greenpeace as we are in dialogue with the stakeholders in the tea Industry and they are willing to work with us." She said she suspects that Crop Care is concerned about its business interests and Greenpeace’s increasing success to guide crop producers – many of which are small farms – toward sustainable management practices that don’t require the use of pesticides.

In August, the Tea Board decided to put a hold on its plans to implement a plant protection code that would spell out the way that pesticides could be used on crops. In a statement explaining why it had put a halt on implementing the code on Sept. 1, the board stated that while larger companies were cognizant of proper pesticide use, many of India’s smaller estates needed more guidance. It did not say whether this was a reflection of the Greenpeace study, in which researchers found DDT in more than half of the samples tested.

Saigal said the point of the study, which is so far the largest of its kind in India, was to encourage better regulation of tea cultivation and pesticide use.

“[The] regulatory system that regulates pesticides in India is in shambles," she said.

The Tea Board’s deferment of the plant protection code is evidence that it may be listening to concerns -- a choice that has received a good response from the public, Greenpeace said. Still, the nonprofit’s challenges aren’t over. A recently leaked Intelligence Bureau document implied that the advocacy organization was “a threat to national security” because it “negatively [impacts] economic development." It was not the only NGO to be named in the report

Saigal called the statement “suspicious,” but said it hasn’t had much impact on the NGO's dialogue with the tea industry. “[Tea] companies as well as the Tea Board continue to engage with us.”

“This study is meant to be a wake up call for the tea industry to move towards holistic ecological approaches. In our report we have found some unapproved pesticides clearly suggesting that the current regulatory system is failing to regulate pesticides. While the Industry has taken some initiatives it is only a piecemeal approach which is not the right solution,” Saigal said.

The Tea Board’s plant protection code is now slated to take effect Jan. 1, 2015, leaving plenty of time for updates on crop management education in the tea industry. It will be interesting to see if it also yields a reduction in pesticide use, as India continues to upgrade its global standing in this increasingly profitable market.

Image credit: Greenpeace India

Business Risks and Opportunities in a Carbon Surge Economy

Business now operates within a carbon surge economy: Carbon surge -- rapidly rising concentrations of atmospheric greenhouse gases -- is rapidly raising the risks and cost of doing business. Extreme weather tied to the carbon surge is reducing business revenues by disrupting customer access to stores and websites. Increasing evidence of climate change tied to the carbon surge is pushing consumers, especially the millennial generation, to question what they buy and who they buy from.

This consumer shift is threatening utility revenues while growing the sales of smart, energy efficient technologies. The net result is the emergence of an economy defined and shaped by carbon surge.

Carbon surge evidence

The World Meteorological Organization’s latest report finds that a carbon surge in climate-changing emissions has pushed atmospheric CO2 concentration to 142 percent of the pre-industrial era, with methane and nitrous oxide levels at 253 percent and 121 percent of pre-industrial levels. The ocean’s ability to absorb greenhouse gases may have reached its limits -- with ocean acidification now at levels unseen for over 300 million years.

Carbon surge’s threat to business costs

A carbon surge economy is a costlier place to do business. Examples of how carbon surge and the inceased incidence of extreme weather are increasing business costs include:

- Rising electricity and fossil fuel costs tied to increased regulation of climate changing pollution;

- Increased commodity costs, plus increased price volatility, as extreme weather events disrupt or destroy supplies;

- Increased property insurance tied to the increase in extreme weather damage claims;

- Lost productivity due to electrical service disruption;

- Lost productivity due to storm and weather related worker attendance disruptions.

Carbon surge economy reshaping management best practices

A carbon surge economy has become a business management reality. The carbon surge is reshaping how a business manages risks and costs. For example, a recent study by Business Forward found that a single hour of extreme weather disruption at an automobile assembly plant costs $1,250,000. This scale of cost is a principal driver in the auto industry's increased focus on sustainable best practices, lean manufacturing and zero waste/emissions technologies.

Businesses around the world, including Apple, Dupont and Walmart, are developing new business best practices that address the risks and costs created by carbon surge. These businesses are pioneering the development of green business supply chains to reduce costs tied to extreme weather. Proven lean manufacturing techniques are being applied across industries to re-engineer factories and offices. Their experiences are that zero waste and zero net emissions investments not only reduce environmental impacts but also costs.

Companies are also beginning to add the cost of carbon surge into their financial decisions: Today at least 150 worldwide companies, including ExxonMobil, Google and Microsoft, use an assumed carbon tax in their planning and capital assessment processes.

Winning business in a carbon surge economy

The news is good for those businesses that can develop carbon surge solutions. Pioneering technologies -- ranging from electric cars to smart thermostats to onsite solar systems -- are gaining economies of scale that are enabling price-competitive alternatives to carbon-based fuels and technologies. A green economic revolution has already begun. The potential is that by 2017 a sustainable global economy of lower carbon and zero carbon solutions will achieve $10 trillion in world commerce -- equal to 20 percent of the global commerce.

Competitive advantages will accrue to businesses that can implement solutions to carbon surge. These businesses will have lower costs. They will have increased service reliability. They will better align with customers seeking solutions to “in me, on me and around me” costs created by carbon surge.

Here are three steps every business should pursue to win competitive advantage in a carbon surge economy:

1. Net Zero Energy (NZE) Building Design. NZE buildings are designed so they consume from the fossil-fueled grid no more than what the building can self-generate from onsite renewable power systems. Energy efficiency and smart technologies, including real-time integration of onsite batteries and renewable generation systems, are key NZE design features. A NZE building design holds the potential of lower operating costs, especially as utilities raise their rates to pay for carbon surge impacts like increased power plant emissions regulations and the costs of grid disruptions caused by extreme weather. Every business should begin the path toward making their building NZE by investigating LED lighting, exploring if your utility allows rooftop solar panels and retaining a “green” architect experienced in space design alternatives that promote energy efficiency. If you lease your space, then approach your landlord about a “green lease” that addresses issues of energy efficiency and utility reliability.

2. Green Supply Chain. Reducing carbon in business supply chains and product designs is proving to not only reduce environmental impacts but also costs. Evidence continues to grow that green supply chains operate at a lower cost, and the green supply chain is emerging as a business best pratice. Many business suppliers stand ready to help their customers learn about and implement proven green best practices that will save money and reduce environmental impacts.

3. Green Teams. Engaging work associates through green teams is a proven best practice for lowering costs and generating creative ideas that will win customers. Today’s millennial generation work associates are searching for meaningful engagement from their work. They want to be part of the solution in improving the health of people and the planet. There are now proven best practices for structuring green teams of work associates to motivate them to design and implement ideas that will reduce business costs, reduce business risks tied to environmental impacts and develop new paths for winning customers.

Image credit: Flickr/Elizabeth Stilwell

Bill Roth is an economist and the Founder of Earth 2017. He coaches business owners and leaders on proven best practices in pricing, marketing and operations that make money and create a positive difference. His book, The Secret Green Sauce, profiles business case studies of pioneering best practices that are proven to win customers and grow product revenues. Follow him on Twitter: @earth2017

Work More and Warm Less: Integrating Jobs and Climate Solutions

By Rob Wolcott

As citizens and world leaders converge on New York City seeking a way to address climate change, across the U.S. tens of millions are also out of work. The political challenge of achieving a climate policy consensus is hard. There is no broad agreement that the U.S. even has a climate problem. But there is bedrock consensus that we have an unemployment problem, and tackling it may be one of the best ways to help the climate.

Monthly jobs reports indicate U.S. unemployment a little over 6 percent, representing about 11 million people. But that ignores at least another 10 to 12 million Americans who want to work, but are so dejected by the lack of jobs that they have given up looking. The labor force participation rate (the percent of healthy, working-aged adults with jobs) is 62.8 percent, the lowest in 35 years. That means almost 40 percent of Americans are jobless -- many by choice, but many, many others for lack of opportunities.

Factors driving this crisis include a skills/needs mismatch, labor-saving mechanization, globalization, a hangover from the Great Recession and a chronic, self-inflicted problem of double taxation of labor. On top of personal income taxes, our payroll taxes raise hiring costs and encourage employers to use more energy and less labor. Labor and energy/materials are relative substitutes in the overall economy: In general, the more a business uses one, the less it uses the other.

That’s why, even though at first glance jobs and climate seem to be distinct policy questions, they are in fact deeply intertwined. For more than a century through tax policy and other means, development and use of fossil fuels have been incentivized and subsidized. Today with only 5 percent of the global population, the U.S. consumes 20 percent of the world’s fossil fuels. Fees or taxes on energy would cut greenhouse gas emissions more efficiently than regulation, yet we’ve failed to put a price on carbon, and therefore failed to curb energy consumption driving climate change. We currently don’t tax and therefore effectively subsidize climate pollution; but for 75 years we’ve taxed work and job creation, which leads to greater energy consumption and climate pollution.

We could correct this if Congress authorized a modest emission tax or fee on all fossil fuels and other greenhouse gases (GHGs), and used the revenues to offset payroll taxes, which undercut employment. If we started with a fee of $20 per ton of carbon, it would generate $150 billion to $200 billion per year. The level could be adjusted over time to achieve science-based emissions targets to mitigate climate change. Revenues would increase as the rate of taxation increases, eventually flattening out as we reduce consumption and increase energy efficiency.

Revenues generated from carbon fees could be dedicated to a fund to offset part of the Social Security payroll tax for both employers and employees. The payroll tax would remain in place, with most (e.g. 80 percent) of the emissions revenue funding payroll tax rebates. The rest could fund other programs to buffer the impact of higher energy prices on low-income households. This tax shift would be phased in over time allowing firms, governments and households to adapt to new prices through technology changes and shifts in consumption.

This proposal is easily administrable, revenue neutral and market-based, relying solely on the price-induced behavioral changes of producers and consumers. It strengthens Social Security by expanding and diversifying its funding base without threatening or altering its structure, and it expands long-term economic growth by correcting tax-based distortions of the relative prices of labor vs. energy and other inputs to business that aggravate GHG emissions.

Because half of federal payroll taxes are paid by firms and half by employees, reducing them would reduce the cost employers pay for new hires and current workers, and would increase workers’ take-home pay. That will expand labor demand and supply, and keep expanding them over time as firms adjust their production systems. Emissions will shrink as producers and consumers adjust to a new balance between lower labor costs and higher fossil fuel prices, which will incentivize new energy efficiencies and technologies. We’ll be better off economically and environmentally.

The policy key to achieving this is to redraw the inverse relationship between energy use and employment, and keep connecting our need to address climate change to our need to create jobs. They’re twin policy imperatives: To warm less, America must work more.

Image credit: Flickr/Elizabeth Stilwell

Robert M. Wolcott is Senior Economic Adviser to Get America Working and Former Deputy Assistant Administrator for Policy, U.S. EPA.

Lyft, Uber Dethroning Taxi Industry in San Francisco

The San Francisco taxi industry is on the verge of being dethroned by transportation network companies (TNCs) such as Lyft and Uber. Last week, the San Francisco Municipal Transportation Agency (SFMTA) reported that the average trips per taxicab in the city had declined from 1,424 a month in March 2012 to only 504 as of July 2014 — a nearly 65 percent drop.

The taxi industry's health "overall is being impacted clearly" by competing transportation network companies, said Kate Toran, director of Taxis and Accessible Services for the SFMTA.

Fueled by copious amounts of venture capital, Uber and Lyft have been locked in a vicious battle for the transportation throne. In a bitter conflict for users and drivers alike, the leading TNCs have left a festering taxi industry in their wake.

"There's been a real reduction, but obviously this doesn't tell the whole story. Part of the story is we don't have hard data yet from the [transportation network companies'] side to really analyze the full impact on the streets and our air quality."

Toran has approached the California Public Utilities Commission (CPUC) about conducting a joint study with the SFMTA on the impacts of taxis and TNCs competing in the for-hire transportation industry. CPUC established the new business category in September 2013 and is responsible for regulating TNCs such as Uber and Lyft.

One of the major implications of a shrinking taxi industry is that it is making it more difficult for those living with disabilities to find a ride. Many taxi fleets require a certain number of accessible vehicles to be on the road at any given time, which can be dispatched by phone. In December 2013, Taxi Mecca New York City settled a major class-action lawsuit and adopted regulations requiring half the city’s more than 13,000 yellow cabs be accessible to people with disabilities within six years.

But TNCs are not required to accommodate wheelchairs, which has created accessibility problems for members of the disabled community trying to use Uber and Lyft. However, CPUC has mandated that TNCs develop an “Accessibility Plan,” including modifying apps so they “allow passengers to indicate their access needs,” among other things.

Lyft, Uber, Sidecar and two other TNCs filed disability-access plans with the CPUC, claiming that they will ensure drivers don’t discriminate against disabled customers. The companies said they already have or soon will make their apps and websites accessible to blind users, but they maintained that drivers can still determine whether or not to allow service animals in their vehicles.

Another challenge facing TNCs as they strive to become more accessible to the disabled community is that they don’t own any physical fleets of vehicles — they only provide the technology platforms that allow passengers and drivers to match themselves for a shared ride. Few Uber or Lyft drivers would be willing to go through the expensive and aesthetically-hindering process of modifying their personal vehicles for accessibility. As I wrote earlier this year, the most realistic solution seems to be TNCs partnering with paratransit companies, which already have the proper vehicles and trained drivers to assist the disabled — but this is much easier said than done.

According to Toran, total wheelchair pickups by wheelchair-accessible taxis dropped from 1,378 per month in March 2013 to 768 per month this past July because it was difficult to get drivers to commit to the program that takes more time and money.

"The ramp taxi program is just a vulnerable program in the taxi program overall because it costs more to operate, maintain and it costs more in gas for the drivers," Toran said. "It takes more time to do wheelchair securement, so it's kind of the first to go."

In an attempt to increase incentives for drivers to join and stay in the taxi industry, the SFMTA waived dispatch renewal, color scheme renewal and driver application fees for fiscal year 2014-2015, reduced some medallion-use and renewal fees, and eliminated metal-plate fees. The agency is also exploring other ways to make taxi driving more financially attractive, such as reducing fees for medallions, which allow holders to operate taxis. Other ideas include reducing the fee to transfer medallions by 20 percent, eliminating the $500 ramp taxi medallion use fee, lowering the medallion renewal for transferrable medallion holders and allowing taxi-wrap advertising.

All of this seems like the last desperate acts of a dying industry. As more and more consumers adopt smartphones and lead app-driven lives, they are going to be turning to apps to drive them. Taxi companies’ only hope for survival is to accept that times have changed and adapt to new technology — a good start would be joining up with companies such as FlyWheel, which uses Uber- and Lyft-like technology to connect users to taxis via their smartphones.

As TNCs continue their wayward struggle for the hearts and minds of today’s tech-savvy consumers, they ought to keep one thing in mind: When you dethrone the king, you inherit his kingdom, along with all the responsibilities to serve his people — all of his people.

Currently based in Washington, D.C, Mike Hower is a writer and strategic communicator helping to drive the conversation at the intersection of sustainable business and public policy. Connect with him on LinkedIn or follow him on Twitter (@mikehower)

Sustainable Seafood is On the Rise, New Reports Show

Although 29 percent of the world’s oceans are overfished, 10 percent of global wild caught seafood comes from fisheries involved in the Marine Stewardship Council's program. Since 1999, more than 220 fisheries have undergone independent assessments of their environmental sustainability, and those who have achieved MSC certification have made hundreds of improvements to their fishing practices. MSC-certified fisheries committed to making 600 additional improvements by 2020.

Two recently released MSC reports, the Global Impacts Report 2014 and the Annual Report 2013-14, show that there are more MSC-labeled products than ever before. Over the past five years the amount of MSC-labeled products have more than doubled. More than 23,000 products from MSC-certified fisheries were available in over 100 countries -- a tenfold increased since 2009. The amount of fisheries participating in the MSC program with habitat and ecosystem impacts at or above best practice has increased from 71 percent in 2009 to 82 percent in 2013. The amount of fisheries in the MSC program with stocks mained at or above maximum sustainable levels has also jumped from 80 percent in 2009 to 94 percent in 2013.

Fisheries participating in MSC help the environment as they continue to improve

Fisheries participating in the MSC program are improving: Fisheries certified between 2000 and 2009 completed all of their improvement action plans by the end of 2013. Over 50 percent of action plans were completed in the third to fourth year after the initial certification. It's also worth noting that fisheries certified in 2010 completed more action plans by the third annual surveillance audit than in previous years.

MSC-certified fisheries benefit the environment, as examples in both reports show. Toothfish varieties, more commonly called Chilean sea bass, were viewed as overfished and at risk just a few years ago. Now, they have made turnarounds, and there has been 100 percent observer overage on vessels to ensure compliance with management regulations to prevent overfishing. Currently, 54 percent of the global toothfish supply is MSC-certified, with 16 percent more in the assessment process.

Other examples of improvements include:

- The South Africa hake fishery has implemented measures that lead to a 90 percent reduction in seabird mortalities since 2009.

- The New Zealand hoki western stock has more than doubled since its first certification in 2001.

Consumers buy more MSC-labeled products and recognize the MSC label

Consumers are buying more MSC-labeled products, the reports note. The retail market value of sustainable seafood with the MSC label reached $4.8 billion in 20013-2014. There has been an 11 percent increased in the purchase of MSC-labeled products since 2010. In 2014, an average of 40 percent of seafood consumers in all countries surveyed bought MSC-labeled products at least once or twice.

Consumers also recognize the MSC label: In 2014, 36 percent of consumers in surveyed countries who bought fish at least once every two months recognized the MSC label. When consumers were shown the MSC label without text, between 20 and 58 percent recognized it, and 11 percent could accurately describe what the MSC label stands for.

Image credit: Marine Stewardship Council

The Most Common CV and Resume Mistakes, Part 1: It's All About Me

By Shannon Houde

The most common mistake a job applicant can make is to think that their CV is all about them. As a sustainability career coach and former HR manager, I know this only too well. "But I can't delete that sentence!" a client will cry. "That project 10 years ago was really important!" I hear it all the time and, frankly, yawn. Because guess what? You can extract parts of your history and still be okay. In fact, you will be more relevant and marketable.

No matter what your college career advisor told you, your CV is most definitely not about you. It's a marketing tool. Therefore, it should be all about the market: appealing to the hiring manager, meeting the company's needs, using the organization's language, communicating what your audience wants to hear. A CV that goes into every tiny detail of your entire career history is absolutely not what a hiring manager wants to read. You have to do the screening work for them.

If you’re still not convinced, put yourself in their shoes: You've got 30 seconds to find out whether this person can do the job or not, what motivates them, whether they fit the company culture, and whether or not you want to work with them.

So if you want to avoid making this simple error, there is some work to do before you start writing your CV, and -- counterintuitively -- that work does start with you. Specifically, knowing yourself. The reason? By knowing yourself, you are in a better position to market and ultimately sell yourself. My bespoke framework was developed specifically for this purpose. It takes the pain out of the self-scrutiny by focussing on how you'd answer a hiring manager's four key questions before they've even asked them, and I'm going to share it with you here.

Hiring Manager Key Question 1: "Do you fit our company culture and team?" Also known as "What motivates you?"

This question is all about your values, your core beliefs, your ethics, the things that you hold true throughout your life -- not just at work. Your task is to come up with five or so nouns or short phrases that communicate your values. For example, 'respect,' 'making a difference,' 'holistic view,' 'leadership,' 'accountability' ... These are all good, strong professional values. What are yours?

Hiring Manager Key Question 2: "Do I want to work with you?" Commonly disguised as "How would someone describe you?"

This question is all about your traits and characteristics -- basically the way in which you deliver on your skills. It's your work style, your approach to your job, and it tells the hiring manager everything they need to know about whether you are someone they want to see every day, or even grab a drink with after work. Examples of traits or characteristics include adjectives like 'collaborative,' 'authentic,' 'persevering,' 'calm under pressure' and 'intrapreneurial.' Which words best describe the sort of colleague you'd be?

Hiring Manager Key Question 3: "Can you do this job?" Sometimes posed as "Walk me through your CV."

This is to figure out if you can actually do what the employer will be paying you for. It's your skills and relates specifically to the job tasks and what you'll be doing every day at the office. Think of measurable and tangible words, terms or phrases like 'develop strategy,' 'influence buy-in,' 'manage projects and teams,' 'engage stakeholders,' and 'drive bottom line.' This is a quick, easy way to communicate what you can do, but make sure you choose words that are backed up elsewhere in your CV -- don't get off track from your “story."

Hiring Manager Key Question 4: "What do you know about key CR/sustainability issues?"

This is about your knowledge, your speciality, your niche - and you need to narrow it down to between two and four. It could be sustainable supply chains, human rights, waste, water, or renewable energy ... You get the idea. This is your chance to show off your expertise, so focus! Maybe you could impress that little bit extra by linking your expertise to one of the company's sustainability KPIs. Now that's employable!

So before you dig out that old CV from your computer's hard drive and start tidying it up, spend a couple of hours reflecting on the above questions and come up with five or so words in response to each one. And remember, be clear, be concise! You've got 30 seconds, and counting.

Next month in Part 2 of this series, I'll explain how to use these insights to map your skills to the market. In the meantime, follow me on Twitter @walkoflifecoach to stay in the loop.

Image credit: the Italian Voice, via Flickr/ CC BY

Shannon Houde is founder of Walk of Life Consulting, the first international career coaching business focused solely on the environmental, sustainability and corporate responsibility fields.

Brazil declines to sign UN deforestation pledge

The launch of the UN’s new pledge to slow global deforestation at this week’s Climate Summit in New York was overshadowed yesterday by Brazil’s failure to sign up to it.

The innovative public-private partnership of multinationals, governments, civil society and indigenous peoples was endorsed by countries in the developed and developing world – including the United States, the EU, and a large number of tropical forest countries – as well as by multinationals from the food (Unilever), paper (Asia Pulp and Paper Group) and finance industries.

However Brazil, home to the world’s largest rainforest, declined to sign the declaration citing the measures to end illegal deforestation had been drafted behind closed doors at the United Nations without its participation. A claim refuted by the UN.

The New York Declaration pledges to cut the loss of forests in half by 2020 and end it a decade later in 2030 – a move that will eliminate the emission of between 4.5bn and 8.8bn tons of carbon dioxide each year.

The Declaration is meant to form part of a pact for adoption next year at the Paris climate talks.

The Declaration also calls for the restoration of over 350 million hectares of forests and croplands, an area greater than the size of India, which would bring significant climate benefits and take pressure off primary forests.

“I asked for countries and companies to bring bold pledges, and here they are,” said UN Secretary-General Ban Kimoon. “The New York Declaration aims to reduce more climate pollution each year than the United States emits annually, and it doesn’t stop there. Forests are not only a critical part of the climate solution – the actions agreed today will reduce poverty, enhance food security, improve the rule of law, secure the rights of indigenous peoples and benefit communities around the world.”

To support the New York Declaration, several specific commitments to action were announced. This included three of the world’s largest palm oil companies – Wilmar, Golden Agri-Resources and Cargill, all of which recently announced deforestation-free sourcing policies and who jointly make up more than half of global palm oil trade – committing to work together on implementation, and joined the Indonesian Business Council in asking incoming Indonesian President Joko Widodo to support their efforts through legislation and policies.

While Germany, Norway and the UK said they would push for large-scale economic incentives as part of the Paris climate talks, and in the next couple of years pledged to enter into up to 20 new programmes to pay countries for reduced deforestation rates, if credible programs were put forward.

Picture credit: © Kutt Niinepuu | Dreamstime Stock Photos

Unilever and DFID join forces to help world’s poor

Unilever and the Department for International Development (DFID) have formed a new partnership to create jobs, improve water and sanitation and develop sustainable supply chains in developing countries.

The International Development Secretary, Justine Greening, signed a joint letter of intent with the Anglo-Dutch conglomerate's ceo Paul Polman which commits both organisations to work together to improve the lives of millions of people in developing countries and help end dependency on aid.

The partnership is the first of its kind between a leading international business and the UK’s Department for International Development.

DFID and Unilever will launch a joint initiative to use new social business models to improve health, hygiene and livelihoods for 100 million people by 2025. They will also each contribute £5m to a research and innovation programme focused on affordable sanitation and safe drinking water.

Justine Greening said: “British businesses have the potential to make an enormous contribution to the fight against extreme poverty around the world. This partnership, the first of its kind, will combine our expertise and networks to help millions of the world’s poorest people find jobs, improve water and sanitation and, ultimately, end dependency on aid. This is not just good for the developing world, it is good for Britain. The frontier economies we will be working to improve are ultimately Britain’s future trading partners.”

Unilever, through its Sustainable Living Plan (USLP), aims to double the size of its business whilst reducing its environmental footprint and increasing positive social impact. Their products are sold in over 190 countries and more than half of the company’s presence is in developing and emerging markets. One element of this plan is their work facilitating hand-washing, sanitation and hygiene around the world.

- As part of its mission to help more than a billion people take action to improve their health and wellbeing, Unilever, through its health soap Lifebuoy, has recently joined forces with Fashion 4 Development (F4D) to highlight the lifesaving power of handwashing with soap. An event this week in New York aimed to bring the importance of hygiene programmes for newborn survival to the attention of the influential First Ladies attending F4D’s annual First Ladies Luncheon. F4D works in partnership with the United Nations Millennium Development Goals (MDG), pairing diplomacy and fashion for the greater good of women and children worldwide.

Picture credit: ID 26621451 © A4ndreas | Dreamstime.com

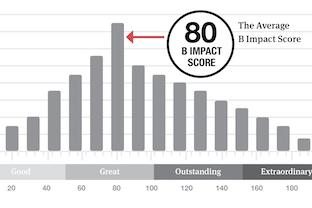

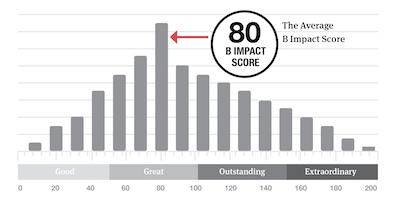

How B Corp Certification Helps Benchmark and Improve Performance

This is the seventh in a weekly series of excerpts from the upcoming book The B Corp Handbook: How to Use Business as a Force for Good (Berrett-Koehler Publishers, October 13, 2014).

By Ryan Honeyman

Many B Corps report that one of the biggest benefits of the certification process is taking the B Impact Assessment, a free tool that measures the social and environmental performance of the entire company on a scale from zero to 200 points.

This enables any business to measure the impact of its operations on its workers, its community, and the environment; compare itself to its industry peers; and compete to improve its performance over time. The B Impact Assessment is particularly valuable because no matter how sustainable your business already is (or is not), you will undoubtedly find blind spots that you can address to further benefit your stakeholders.

"Before the B Impact Assessment, we struggled with aligning our internal processes and assuring our deep-thinking team members that the company was being guided for maximum impact. Now we have a road map and partners that help us establish effective governance practices and policies. Becoming a Certified B Corp put it all together for us." —Regina Wheeler, CEO, Positive Energy Solar

Patagonia is a great example of a company that uses the B Impact Assessment for continuous improvement. On its initial B Corp certification, Patagonia — one of the most eco-friendly companies on the planet — scored 106 out of 200 points. Although earning only half of the points on the B Impact Assessment might seem like a poor performance, Patagonia’s score was well above both the 80 points required for B Corp certification and the median score of 95 points for all Certified B Corps.

Indeed, the B Impact Assessment is designed to be tough. Rather than trying to get a perfect score on the first try (which is virtually impossible, because no company is perfect), you can use the assessment to measure your company’s social and environmental performance, provide valuable insights that can help spark new ideas, and motivate your company to reach for an improved score over time.

"Our biggest surprise, considering our one hundred percent commitment to sustainable materials and ethical labor practices, was that we did not score higher on the B Impact Assessment. It was eye opening to realize that we could still improve in many different areas of our business." —Matt Reynolds, president and co-founder, Indigenous

Some B Corps, such as Ben & Jerry’s and Numi Organic Tea, are going further by using the B Impact Assessment to benchmark their key suppliers. The assessment’s comprehensive, rigorous, and comparable metrics is helping these companies better understand both the overall impact of their supply chain and the individual performance of their various suppliers. Ben & Jerry’s is interested in using the B Impact Assessment to help guide their procurement and sourcing decisions in the future.

In addition, B Corps such as The Redwoods Group, a commercial property casualty insurer based in North Carolina, use the free B Impact Assessment as a guide for their corporate social responsibility reporting. In many cases, substituting the assessment for conventional corporate social responsibility reporting can save considerable time and money.

Ryan Honeyman is a sustainability consultant, executive coach, keynote speaker, and author of The B Corp Handbook: How to Use Business as a Force for Good. Ryan helps businesses save money, improve employee satisfaction, and increase brand value by helping them maximize the value of their sustainability efforts, including helping companies certify and thrive as B Corps. His clients include Ben & Jerry’s, Klean Kanteen, Nutiva, McEvoy Ranch, Opticos Design, CleanWell, Exygy, and the Filene Research Institute.

To get exclusive updates and free resources that can help you learn more about B Corporations, sign up for Ryan’s monthly newsletter. You can also visit honeymanconsulting.com or follow Ryan on Twitter:@honeymanconsult.