The Impact of the Solar Eclipse on the Utility Grid

Utility companies across the country are preparing for the unexpected next Monday when the moon crosses in front of the sun, creating the first total solar eclipse in for the U.S. almost than 40 years. While techies discuss the mechanics and safety of being able to catch the eclipse with a cell phone camera, California's power grid will have it own challenges, like how to balance the drain of upwards of 60,000 megawatts of power during the eclipse.

Although California isn't in the path of the total eclipse, the phenomena is expected to affect power generation for throughout the state. That's because the state receives a substantial amount of its power from the Northwest, which is in the direct path of the eclipse.

California ISO (Independent System Operator), the guys that operate the state's grid, say the anticipated loss of power during the eclipse will be equivalent to what it would take to power 600,000 homes in California. To offset its impact, grid operators are taking a page from the experiences of European grids, which juggled the impact of a near total eclipse with 90 GW of solar power on the grid in 2015.

Solar eclipses are actually quite common, occurring somewhere on the planet about every 18 months. But the increasing dependency on solar power has presented new challenges for grids that source low-emission power. This is also the first coast-to-coast solar eclipse to occur in the States since 1918. This year, the eclipse is expected to do more than momentarily plunge cities into darkness: It will test the very fabric of a budding green energy grid that increasingly relies on solar power.

North Carolina, which is in the direct path of the eclipse, will lose about 90 percent of its sunlight. And unlike in the Pacific Northwest, the drain of solar energy is expected to hit at peak usage time, between 1 and 3 pm, ET, when air conditioners will likely be in full operation.

Operators in both areas say the key to balancing power generation and usage will be taking advantage of the grid's diverse power sources.

"System operators are constantly monitoring demand and making decisions about what source – natural gas, solar, nuclear, hydropower, coal, wind, etc.– is the most efficient for that moment," Duke Energy explained on its website. The state is second only to California in its solar generation, so the eclipse, which is expected to cross over the girth of the U.S. in an arc, has the ability to impact some of the the highest usage areas when it comes to solar power dependency.

Fortunately, many of those areas are already reliant on alternative sources for energy generation. In fact, notes James Conca, an environmental scientist and Forbes contributor, while many would like to see a decrease in dependency on sources like nuclear power across the globe, it's those very alternative power sources that will ensure minimal interruption during environmental events like total eclipses.

"This energy diversity is critical because our energy system has to function through more and more frequent challenges, like extreme cold and Polar Vortices, water droughts and low mountain snowpack, heat waves with wind doldrums, and other problems," Conca writes. In other words, in coming years solar eclipses may be only one of several challenges that grid operators will have to face by juggling an array of technologies on the grid.

The eclipse is expected to cross over 12 states, casting a broad shadow from Portland, Ore. to Charleston, S.C. It's also expected to boost demand on many cell phone providers, which are expecting increased travel to places like Wyoming to see the eclipse. To offset this challenge, AT&T is sending a "cell on wheels," appropriately called a COW in short, to eastern Wyoming to boost network capacity in high-usage areas.

And cell carriers aren't the only businesses expected to reap in the benefits of an extraordinary event. Bed and breakfasts, hotels and other hospitality providers are gearing up for the money-maker, which is among other things, expected to snare traffic in places like Western Oregon and Washington.

Oregon Department of Transportation is warning would-be travelers that the phenomena is likely to herald "the biggest transportation event that has ever hit Oregon." For places like Portland, the state's festival capital, that's saying something.

With warm summer temps extending across the Northwest, this year's unusual eclipse may be a true headache for power companies and cell providers, but it's likely going to be the summer's sweet spot for tourism providers who know these kind of attractions usually come once in a lifetime.

Poop-to-Energy Project Provides Clean Cooking Fuel in Kenya

Sanitation workers, public health officials and entrepreneurs are working together in Kenya to tackle two huge challenges: deal with human waste safely and provide clean cooking fuel for local residents.

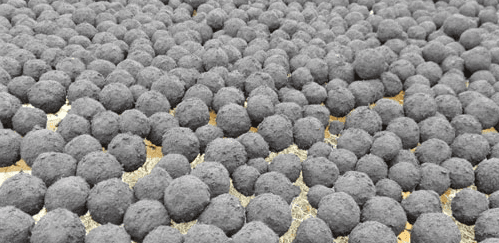

A project in Nakuru, the fourth-largest city in Kenya, is collecting human poop from toilets in selected areas of the city and turning it into biochar briquettes that can be used for tasks ranging from cooking meals at home to keeping chicks warm at poultry farms.

Leading this effort is Nakuru’s local sanitation company, which aims to cover 95 percent of the city and surrounding area with this program. The Nakuru Water and Sanitation Services Company is building its own value chain, starting with the construction of 5,000 toilets in neighborhoods where sewage systems are lacking.

Waste from those toilets, in addition to what can be collected from pit latrines and septic tanks, is eventually taken to a processing facility. Similar in design to that of a greenhouse, waste dries out in these sheds during a two- to three-week process. That sludge is then fired, or carbonized, at a temperature of 700° Celsius. Additional materials such as banana stalk fiber and sawdust are then added; that material is then heated again at 300°C.

Next, the mixture is formed into briquettes, resulting in a charcoal-like product. According to the sanitation company, this fuel has no odor, and also burns far more safely and efficiently than conventional charcoal. Various media sources report that despite initial fears over what the smell of these briquettes may impose, the carbonizing process removes pathogens and they burn cleaner than wood-based alternatives; additives such as molasses, a binding agent, even lend a sweet-smelling aroma (and help users forget the source of this fuel).

In the meantime, the sanitation company is promoting hand-washing and other personal hygiene tactics to improve public health in and around Nakuru, which is home to over 400,000 people.

The project’s leaders hope to attract more funds to expand the program, which would create more jobs while also generating other products such as fertilizer for local farmers. Production capacity is currently limited to two tons a month, but local officials say investment could help quintuple the amount of poop processed into fuel by the end of this year.

On one hand, the project could improve sanitation in this western Kenyan cities, as well in other areas across the world where providing a safe place to use the bathroom while maintaining safe water supplies is often close to impossible. Furthermore, the project also could offer a clean form of fuel cookstoves, the household tool by which meals are prepared in much of the developing world - and also creates its own set of health and environmental problems.

The quest to find alternative sources to burning wood in cookstoves, which contributes to deforestation, has been an ongoing challenge. Some carbon offset programs have focused on finding alternative fuel sources for these cookstoves, as well as finding ways to improve these contraptions’ design - but those efforts have at best witnessed mixed results.

Human waste, however, is a renewable resource. And consumers are slowly but surely getting over the “ick” factor - witness the success of Orange County’s water recycling program in California, for example.

The briquettes appear to be popular with Nakuru’s residents: Quartz reports that the fuel is currently sold for 50 cents a kilo (2.2 pounds).

Other entrepreneurs in Kenya have been trying to harness human waste into fuel, as many residents lack reliable access to sewage systems. One student, for example, designed a biodigester that could turn human waste into clean-burning biogas. And a Kenyan startup has launched a system similar to what is used in Nakuru, but it runs on solar power.

Image credit: Nakuru Water and Sanitation Services

Vanguard Urging Companies to Inform Investors about Climate Change Risks

Investors who manage their own assets, and are keen on vetting companies on their own, may soon start seeing more climate change-related disclosures.

Pennsylvania-based investment management company Vanguard, which says has over $4 trillion in assets under management, is urging more companies to disclose how climate change could potentially have an impact on their business performance.

The company has long enjoyed the reputation for being one of the leading go-to financial institutions for individual investors who seek to manage assets such as retirement funds without a financial advisor. Many those investors have been unaware, or refused to acknowledge, the fact that more companies are realizing that climate risks could have a significant long-term impact – but that will start to change.

Vanguard’s announcement earlier this week will send a signal to more financial services and companies, as well as public companies, that discussions about climate change are no longer a distraction pushed by “activist investors.” My most accounts, Vanguard is the largest provider of mutual funds. After BlackRock, the company is the second largest issuer of exchange-traded funds (ETFs). Vanguard has long emerged as the largest shareholder of many companies, from Ford to Caterpillar to Microsoft. That leverages gives Vanguard a considerable amount of clout when it comes to pressuring companies to develop more stringent climate change disclosures.

While the company has been criticized for not taking a firmer stand on climate change, Vanguard says it has been working with more companies, as well as their shareholders, as more proposals related to environmental and social issues are put up for a vote. Last year, the company said it had worked with a major oil and gas company in encouraging that firm’s management to disclose specifics on how it manages climate-change related risks. Vanguard says it has also partnered with companies to take steps to mitigate risks related to supply chain challenges and environmental problems such as oil spills.

In an interview with Reuters on Monday, Glenn Booraem, Investment Stewardship Officer at Vanguard, explained that the firm’s stance on climate change, as well as shareholder resolutions focused on this issue, have all evolved over time. "Our support for these proposals is not a matter of ideology, it's a matter of economics," he said to Reuters reporter Ross Kerber. "To the extent there are significant risks to a company's long-term value proposition, we want to make sure there is long-term disclosure of those risks to the market."

During proxy season earlier this year, Vanguard joined other investment companies in urging the passage of several climate risk shareholder resolutions at large energy companies including ExxonMobil and Occidental Petroleum (again, two companies where by number of shares held, Vanguard is the largest owner). Those companies’ boards resisted those proposals, urging shareholders to vote against them, but in a shock for those on both sides of the issue, those proposals ended up passing – and by a wide margin.

Vanguard is following the lead of other financial institutions that are insisting companies become more proactive when it comes to alerting current and potential investors about climate change risks. London-based Blackrock, for example, recently said that climate change is a “systemic issue” and that corporations need to work on improving related disclosures. Earlier this summer, one of the company’s management directors declared that “coal is dead” and that any investor seeking returns from that source of fuel longer than 10 years from you is “gambling very significantly.”

That news prompted at least one socially responsible investor fund to step back from its demands on Vanguard. Walden Asset Management announced that it would withdraw a shareholder proposal that had requested a review of how Vanguard voted on various companies’ proxy statements.

“We are pleased that Vanguard is championing climate risk,” the Boston-based company said. “This includes Vanguard’s proxy votes this spring supporting shareholder resolutions on climate change at ExxonMobil and Occidental Petroleum, helping drive majority votes at both companies and a high support level of 62% at ExxonMobil.”

Image credit: Arby Reed/Flickr

Can Private Wealth Close the SDG Funding Gap?

By Abha Malpani

We are seeing a paradigm shift in consciousness that has the potential to mobilize private wealth for public good, and transform the social impact sector as we know it.

According to a recent report by UBS, the size of the private wealth market is US$250 trillion. The UN claims that the annual investment gap to fund the sustainable development goals (SDGs) in developing countries is US$2.5 trillion annually; meager in comparison. More awareness on where impact investments are needed, and how to invest is required.

Increased awareness will be a game changer for the impact investment market

The current size of the impact investment market is between US$114-135 billion, expecting to reach US$307 billion by 2020, according to reports from Global Impact Investing Network (GIIN) and Markets&Markets. In line with the global divestment trend, where millions are choosing to not support shares, bonds or investment funds that are unethical, increased awareness on viable impact investments will grow that market much more.

Every year governments, foundations and individuals spend more than US$500 billion on efforts to improve the world. Of the $500 billion spent each year, less than 0.01 percent is spent on global priorities research. Availability of research informs decision-making and research is exactly what is needed to determine global priorities so that the money available is spent more effectively.

Impact investments can give financial returns

The 2017 Annual Impact Investor Survey by GIIN shows that 91 percent of more than 200 impact investors surveyed had financial returns that satisfied or exceeded their expectations. A 2015 Morgan Stanley report which surveys over 10,000 equity mutual funds over seven years, shows that sustainable investment funds have met or exceeded the median returns of traditional equity funds. Private wealth invested for impact does not have to compromise financial gain.

Millennials and women will drive the impact investment market

Surveys like that of Morgan Stanley and Tridos Bank find that most individual investors are interested in sustainable investing. And, compared to the overall individual investor population, millennials and women are nearly two times more likely to invest in companies or funds that target environmental, social and governance (ESG) outcomes. In fact, studies show that millennials are two times more likely than the average person to divest from a company that does not meet sustainability practices.

Considering that 460 billionaires will soon hand down $2.1 trillion to their heirs over a period of 20 years; and that women already control more than half ($14 trillion) of personal wealth in the U.S. alone (and are expected to control $22 trillion by 2020), the $2.5 trillion needed annually to close the SDG funding gap is not far from achievable.

There are options for every budget

As more businesses with social impact at their core get investor ready, the impact investing landscape has evolved to have platforms to match social investors with social enterprises, irrespective of their budget. These include: GIIN’s Impact Base; Washington-based Impactus Marketplace; New York-based The Impact, and Singapore-based IIX Global. The rise of equity crowdfunding sites; social impact bonds; green bonds; or SRI funds are other ways to invest responsibly and profitably.

Measuring ROI has evolved

One of the biggest obstacles for the impact investment market was lack of industry standard measurement metrics to evaluate social and financial ROI. Addressing this challenge, standardized metrics to measure social impact have emerged over the last few years: the Impact Reporting and Investment Standards (IRIS), and the Global Impact Investing Rating System (GIIRS). This has been a huge step forward for a relatively nascent market.

There is an impending groundswell of opinion in favor of impact investing that can address some of the world's most pressing problems. We need to fuel it with more transparency, awareness and access to information on impact investing opportunities so it becomes a global trend.

Abha Malpani is a writer and communications professional who works towards helping businesses grow in Dubai. She is a strong believer in the triple bottom line and keen to make a difference. In her endeavor to start something of her own, she co-founded Start with Something, a website highlighting stories of people and organizations that are changing the world. She hopes that what she writes will inspire her and others to start something that has an impact. She is also a volunteer member of +Acumen Corps. One day she hopes to have her own social enterprise. You can find her on Twitter @abhamalpani.

How General Mills Celebrates Honey Bees

COMMIT!Forum will convene hundreds of corporate social responsibility leaders and CEOs from CR Magazine’s annual 100 Best Corporate Citizens ranking. The event includes a pre-conference workshop on integrated CSR and sustainability reporting from BrownFlynn. Emcees for COMMIT!Forum include Aman Singh, editor in chief of Futerra, and Icema Gibbs, head of CSR at Jetblue Airways. More information here.

Could you do your job if you were kicked out your house, had no food, and under constant attack by parasites and poisons? Not likely. But this is what life is like for many species of birds, bees and other insects who pollinate our crops and help grow one-third of the global food supply.

The numbers are not pretty. According to a 2016 report from a United Nations group, about 40 percent of pollinator species globally are now facing extinction from threats including mite parasites, industrial pesticides and disappearing habitat. Also endangered are millions of livelihoods and hundreds of billions of dollars’ worth of food supplies. The report further suggested that to reverse these trends will require a combined effort from public agencies and the private sector.

The good news is that a number of those affected are taking a stand, like the recently announced partnership between the food giant General Mills, the U.S. Department of Agriculture's Natural Resources Conservation Service and the Xerces Society, the world's oldest pollinator conservation nonprofit. The group takes its name from the Xerces blue, the first butterfly species in North America to become extinct from habitat loss.

The project aims to add more than 100,000 acres of pollinator habitat on or near existing crop lands over the next five years. The goal is to increase pollinator numbers and diversity. General Mills has pledged $2 million to the effort, the USDA has matched this amount, and the Xerces Society will manage the project.

The money will be used to fund six field biologists on the Xerces team in Minnesota, North Dakota, California, Nebraska, Iowa and Maine. The biologists will work with farmers and ranchers in these regions to develop habitat restoration plans tailored to local biodiversity. Those farms and ranches that opt in are not required to be part of General Mills’ supply chain.

For pollinators, restored habitat provides a diversity of drought-tolerant, flowering native or naturalized plants, as well as egg-laying or nesting sites. The work can take many forms, according to Eric Lee-Mäder, the Co-Director of the Xerces Society pollinator program. These can be field edges or property boundaries planted in high densities of native wildflowers or shrubs. Habitat can also consist of flowering cover crops – such as buckwheat or crimson clover – in rotation with cash crops.

“This model of providing large scale functional habitat with supplier farms will be the wave of the future,” he said, “if we want to continue to eat and continue to source the ingredients that make up our diet.”

General Mills has been at the forefront of this movement, according to Lee-Mäder, and no wonder: The stakes are high for the company. “About 35 percent of our business is impacted by pollinators not only for the grain crops used in our products but also for ingredients like honey used in products like Honey Nut Cheerios brand,” said Beth RobertsonMartin, who leads the organic and non-GMO sourcing group at General Mills. “So of course, we care about the native pollinator species as well as those honey bee hives and colonies.”

In addition to the project with the Xerces Society, General Mills is also working directly with farms in its own supply chain to make them more bee-friendly. Cascadian Farm, one of General Mills organic brands, has committed to planting 3000 to 5000 acres of habitat on the 150,000 acres of farms that support their business. The farms used in the Honey Nut Cheerio supply chain have also committed to plant native wildflower habitat on 60,000 acres of oat farms.

“Success will be measured by the number of acres planted for both the Xerces project and the work we are doing with our supply chain,” said RobertsonMartin. “Our research shows that these habitats do make the difference and impact the number of pollinators when you do it right,” she added.

General Mills is working on multiple fronts in this effort, not only engaging their supply chain but also consumers and employees.

The company’s Honey Nut Cheerios brand ran a #BringBacktheBees promotion earlier this year to give away packets of wildflower seeds for consumers to plant pollinator-friendly gardens. They intended to give away 100 million seeds, but the response was “overwhelming,” according to Mollie Wulff, the Corporate Communications Manager at General Mills. At the close of the campaign, the company had shipped out almost 1.5 billion seeds.

The response from employees has been on a similar scale, according to Wulff. Starting in October 2015, the company set aside a large plot of land on its corporate campus in Golden Valley, Minn., a suburb of Minneapolis. Since then groups of employees have worked together to transform the unused plot into native wildflower pollinator habitat. “It’s been an effective activity to build awareness within our own walls and educate employees about the work we are doing in this area,” she said.

All these projects together will provide multiple benefits for General Mills, protecting a vulnerable part of its supply chain while enhancing brand loyalty from consumers and employees. For other companies considering projects on this scale, Wulff suggests first recognizing that you can’t do this on your own. “If we want to move the needle here, we need to partner with reputable, results-oriented nonprofits, NGOs, and governmental organizations to make an impact. We know we can’t do it alone so we need to work together.”

In fact, Lee-Mäder recommends that everyone should consider getting involved, “No matter how big or small your garden, even if you just have a single flower pot, you can put in a blooming plant and it can become habitat for bees. You can reduce the need for insecticides in your garden. And as a consumer you can embrace brands that are working to reduce the use of pesticides in their supply chain and increase the role of habitat. Those are the core principles of pollinator conservation and regardless of who you are you can plug into that movement.”

Want to plug in and get involved in National Honey Bee Day? Check out these tips from Cascadian Farms and the Xerces Society on things you can do to bring back the pollinators.

Image credit: Celeste Ets-Hokin

AFL-CIO, Top U.S. Companies Flee President's Manufacturing Council

President Trump's failure to respond vigorously to last weekend's display of white nationalist violence in Virginia is being met with an equal and opposite response by some of the nation's top corporate citizens. In the latest development, AFL-CIO President Richard Trumka quit the president's American Manufacturing Council, following the lead of the heads of Merck, Intel and Under Armour.

The moves are more than symbolic. Trump pivoted his presidential campaign around creating new manufacturing jobs and he continues to lean on that theme while in office. Losing hearts and minds in the upper echelons of the industry is not a particularly effective way to support that rhetoric.

AFL-CIO makes up for lost time

Trumka took an extra day to announce his resignation, perhaps taking time to secure sign-off for the strong words he used. While other directors were circumspect, Trumka did not beat around the bush:

I cannot sit on a council for a President that tolerates bigotry and domestic terrorism; I resign, effective immediately. pic.twitter.com/ip6F2nsoog

— Richard L. Trumka (@RichardTrumka) August 15, 2017

Intel: what was inside, is now out

Similarly, Intel CEO Brian Krzanich did not mince words. In a blog post on Monday night, he stated that his intention in resigning was to "call attention to the serious harm our divided political climate is causing to critical issues."

Though he does not mention the president by name, he all but lays the blame on Trump personally:

"...earlier today I called on all leaders to condemn the white supremacists and their ilk who marched and committed violence. I resigned because I want to make progress, while many in Washington seem more concerned with attacking anyone who disagrees with them. We should honor – not attack – those who have stood up for equality and other cherished American values. I hope this will change, and I remain willing to serve when it does."

The blog post closes with a plea to set aside politics and "focus on what is best for the nation as a whole."

Intel's absence means Dell is the only tech company left on the council. Dow Chemical, Nucor, CE and others remain.

Merck takes the heat

As of this writing, Krzanich has not become the target of one of the President's notorious Twitter attacks. It's a different story for Merck CEO Kenneth Frazier.

Although Frazier also did not mention Trump by name, he did personalize his decision to withdraw from the Manufacturing Council, stating that, "as a matter of personal conscience, I feel a responsibility to take a stand against intolerance and extremism."

That almost instantly provoked a series of two Twitter responses from President Trump, who took the opportunity to prevail upon Merck to "LOWER RIPOFF DRUG PRICES."

The attack may come back to bite Trump. Longtime CNBC pundit Jim Cramer is among those pointing out that under Frazier's leadership, Merck is "has not been at the forefront of raising prices for the sake of raising prices."

No word yet on whether or not Trump is working on new federal policies that would actually help make drugs more affordable. In fact things seem to be moving in the opposite direction.

Under Armour, over and out

The case of Under Armour is particularly interesting because it involves a celebrity endorsement issue.

Under Armour got its brand into hot water last February when CEO Kevin Plank offered up some mild praise of President Trump in the course of a televised interview.

That was a bad move considering that the company is headquartered in Baltimore, where Hillary Clinton garnered almost 85 percent of the vote (she won Maryland with just over 60 percent).

The timing was also horrible. The interview took place shortly after the rollout of Trump's first Muslim ban, and hundreds of U.S. companies were already taking a public stand against the President.

Piling on the hurt was Under Armour spokesperson Dwayne "The Rock" Johnson. He posted a vigorous response on Instagram:

“I partner with brands I trust and with people who share my same values. That means a commitment to diversity, inclusion, community, open-mindedness and some serious hard work … Great leaders inspire and galvanize the masses during turbulent times, they don’t cause people to divide and disband. My responsibility here is not only to the global audience we serve, but also to the thousands of workers who pour blood, sweat, and tears into making Under Armour strong.”

Plank quickly backpedaled but the company retained its membership in the Manufacturing Council -- until now.

On Monday Plank deployed his Twitter account to make it clear that "Under Armour engages in innovation and sports, not politics." The full statement was posted on the Under Armour website:

“...I am appreciative of the opportunity to have served, but have decided to step down from the council. I love our country and our company and will continue to focus my efforts on inspiring every person that they can do anything through the power of sport which promotes unity diversity and inclusion.”

Plank refrained from going so far as to call out President Trump by name or make reference to the violence in Virginia, but his meaning was clear.

Judging from the comments on Monday's tweet, his meaning was also clear to people who use their wallets to make political statements:

The bottom line benefit of cutting ties with Trump

Like many companies in the apparel and sporting goods sector, Under Armour took a beating in the stock market last year.

The decision to cut ties with Trump probably won't hurt the company's bottom line and could very well help, partly by freeing it up to take more vigorous positions on other matters supported by popular opinion.

Plank already has a good jump on the issue of climate change. He registered Under Armour's official position on June 2, the day after Trump announced that the U.S. would back down from its climate pledge:

"...I believe in keeping one’s word and doing everything possible to execute on our commitments.We at Under Armour are disappointed by the Administration’s decision to withdraw from the Paris Climate Agreement...Climate change is real and must be taken seriously by our business community, our customers, our neighbors and our elected officials. Sustainability has always been part of our DNA: it’s integral to how we live and work and is essential to our environment. As a business leader concerned with creating American jobs, I disagree with the decision to exit the Paris Accord.

Our word matters and it is our collective responsibility to help protect Mother Earth."

Expect to hear more from Plank -- and other top business leaders -- in the weeks and months to come.

Image credit: Under Armour

Check Out Airbnb's Response to Hate Groups -- Worth Emulating

The First Amendment of the U.S. Constitution prevents Congress from making laws that restrict the freedom of expression, no matter how hateful or hurtful. Court rulings over the years have set precedent for how far such limits can be pushed, but for the private sector, the rules do not apply. The list of folks who have been nailed for the words they blurted out from their mouths is a long one: sports personality Jimmy “The Greek” Snyder, actor and comedian Michael Richards and professor Lisa Durden are just a few examples of those who lost their jobs or reputation for ill-timed comments or rants.

To that end, Airbnb, which has not always had the most pristine record when vetting its guests and hosts, has emerged as a leader in the fight against those who promote hate and racial superiority. As Gizmodo reported in the days before Charlottesville turned into a war zone, “Airbnb won’t put a roof over the heads of Nazis.”

Gizmodo’s Bryan Menegus and Tom McKay reported how Airbnb employees proactively banned some “Unite The Right” marchers from using the online accommodation service during their visit to Charlottesville.

Airbnb claimed that those users who had their accounts cancelled violated the company’s Terms of Service, which includes a nondiscrimination policy:

“We welcome guests of all backgrounds with authentic hospitality and open minds. Joining Airbnb, as a host or guest, means becoming part of a community of inclusion. Bias, prejudice, racism, and hatred have no place on our platform or in our community.”

It has been a very bumpy road for Airbnb up to this point, as over the past couple years, the company was accused of turning a blind eye on hosts who discriminated against potential guests based on their ethnic or racial background. The company eventually brought on some big guns such as former Attorney General Eric Holder to revamp their anti-discrimination policies. The company made news headlines again earlier this year when an Asian-American graduate student documented a text conversation with a host who told her, “One word says it all. Asian” when canceling her reservation. Airbnb recently worked with California’s housing department to find a resolution to that dispute.

The same cannot be said for other technology companies in Silicon Valley and beyond when it comes to showing leadership.

For example, the web hosting and domain registration company GoDaddy removed the white supremacist site Daily Stormer after it posted a vile article about Heather Heyer, who was killed in Charlottesville on Saturday. But that announcement only came after many citizens called out GoDaddy on Twitter.

Speaking of Twitter, that company has also struggled to manage hate speech. Last summer, Twitter banned Milo Yiannopoulos, then an editor for Breitbart news, from its platform over his harassment of Saturday Night Live and Ghostbusters actress Leslie Jones. But Yiannopoulos was only kicked off after outrage had amplified to the point at which Twitter’s executives could no longer look the other way. The company has long been accused of not only tolerating online abuse and hate speech, but even accommodating it. “A honey pot of a--holes” is how one former employee described the company in a report by Charlie Warzel on Buzzfeed last summer.

Facebook has also been accused of moving slow to stop such banter on its social network - and has sometimes been clumsy as it has attempted to moderate discussions over ethnicity and race. The company says it has been on a hiring spree to moderate these posts, but critics say the company has been both slow to respond and is often far too reactive.

As April Glaser on Slate recently concluded, Airbnb can actually offer lessons to its peers in the online world:

“Those sites can still follow Airbnb’s lead: When people in your community complain, you need to investigate and take action. That means not being afraid of pissing off thousands of people who use their platforms to share hate speech—which, yes, sometimes bleed into broader accusations of partisan bias, which social media sites are particularly loathe to incur.”

In this tumultuous time, more companies will find themselves called to take a stand. If they are as proactive and definitive about it as Airbnb, they will minimize the negative fallout.

Image credit: Voice of America/Wiki Commons

T. Rowe Price Employees Revive Baltimore’s Oyster Population

Baltimore, Maryland shares two things in common that at a first glance, appear to be completely unrelated: T. Rowe Price and oysters. The former is a brokerage firm that transformed how stocks and bonds were sold to consumers, has been in business for 80 years and currently manages over $900 billion in assets. The latter is native to Baltimore’s harbors and Chesapeake Bay, and in fact, was once one of the city’s dominant industries during the nineteenth and early twentieth centuries. But Maryland’s oyster population has been decimated for decades, which is one reason why the state is now known more for its blue crab.

Now, T. Rowe Price employees have the opportunity to volunteer on a project that aims to revive the Chesapeake Bay’s oyster population.

They worked with the Great Baltimore Oyster Partnership, a multi-stakeholder effort that brings various residents together to raise baby oysters in the city’s famous Inner Harbor and transfer them to a protected marine sanctuary in the Patapsco River, one of the bay’s most important estuaries.

The project is critical to the Chesapeake Bay’s long-term health, as agricultural runoff and real estate development have damaged ecosystems across the region. Maryland’s famous blue crab is just one example of a local fishery that has come under threat, but the combination of environmental protection and consumer awareness has allowed this creature (and favorite meal during summertime) to recover slowly in recent years.

T. Rowe Price’s work with the Oyster Partnership pays dividends beyond completing some of the grunt work necessary to help oysters reappear and hopefully thrive in the Chesapeake in the near future. The project’s leaders hope these employees can be part of a growing base of “citizen scientists” who can help spread the word of the Chesapeake's challenges and how bivalves such as oysters can improve the bay’s health.

Scientists generally agree that oysters are key to improving biodiversity and water quality within marine ecosystems as one of these creatures can filter up to 50 gallons a day.

Similar coastal ecosystems restoration efforts are underway up north in New England, where some 3-D ocean farms are raising both mollusks and seaweed - which on one hand, not only produce a sustainable source of food, but also help maintain and improve the health of marine ecosystems.

The process of raising these oysters starts in the fall, when baby oysters, or “spat,” are implanted on oyster shells and placed into cages at various locations across the Inner Harbor. Depending on need, T. Rowe Price volunteers periodically visit and clean the cages, while also removing algae and sediment to ensure that the young oysters gain the required amount of of food, sunlight, and oxygen. By late spring, the oysters are ready to be moved to their new home in the Patapsco River.

As a result, T. Rowe Price employees have contributed to the Oyster Partnership’s work in raising at least 270,000 oysters since 2013. “Creating a healthy Inner Harbor will continue to be an uphill battle,” said Shannon Cuffley, one T. Rowe Price employee who helps with this oyster gardening program. “In the wild, the oyster success rate is only 1%. Within this program, the success rate is 70-80%.”

Image credit: T. Rowe Price

How to Address Profitability in CSR Communications

By Jenna Cyprus

The third "p" of triple bottom line clearly highlights the importance of "profitability." However, it seems like many businesses are weary of discussing their CSR success in relation to financial success. Do you understand what it looks like to effectively communicate sustainability in pursuit of bolstering your brand image (and profits)?

The Role of Effective Sustainability Communication

There’s tremendous value in doing something good and not seeking recognition.

But this idea of staying silent when you do something good does not carry over into the business world. Communicating to the public the positive things your organization is doing is necessary in order to maintain positive branding. The following equation is relevant when studying the link between sustainability and success:

Sustainability + Good Communication = Profitability

If you take away good communication, it’s nearly impossible for an investment in sustainability to provide a business-side return.

Effective communication about what’s happening in the area of sustainability will drive profitability – but the key word here is “effective.” There are right and wrong ways to go about communicating progress in this area.

Every situation is different, but here are some things to think about:

1. Prioritize responsiveness

Effective communication is all about engaging stakeholders in palpable ways. When customers reach out to your brand, how are they treated? Do their questions, comments, and concerns get ignored or pushed to the back of the queue? Or are they engaged in a manner that shows they’re important to the organization?

Once you start communicating sustainability to consumers, the frequency of interactions you have with customers will intensify – and you have to be ready. The more efficiently you respond, the more customers will be willing to engage you on this topic in the future.

Seventh Generation, a growing company that provides safe and effective household cleaning products, is one example of a company that prioritizes responsiveness in their sustainability initiatives. All you have to do is browse their Instagram account and you’ll see how they frequently respond to comments and interact with followers.

2. Leverage social media

Speaking of social media, this is something you really have to prioritize moving forward. As expert Matthew Yeomans said, “It has become the mainstream and is embedded in every form of online communication but also in the sensibilities and expectations of everyone online. So how companies understand and use social media to communicate their sustainability activities will only grow in importance as it too becomes part of the business communication mainstream.”

If you want to understand what it looks like to effectively leverage social media, check out what Johnson & Johnson does. As part of their “Commitment to Caring,” they use their official Twitter account to curate and share content that spotlights some of the different things the company is doing to promote sustainability around the world. It’s a simple thing that ultimately makes a big difference by showing people tangible evidence of the company's CSR initiatives.

3. Evangelize your employees

Internally, strong communication helps you efficiently implement change and get your employees on board. If employees don’t know what’s going on, they won’t be able to effectively advocate for your brand’s efforts. Externally, communicating sustainable practices and strategies ensures you’re able to recruit top talent and reach “green” consumers. Why is it, then, that so many companies forget about this important aspect of the equation?

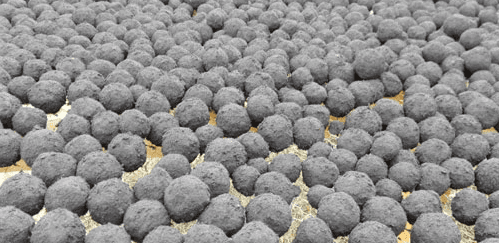

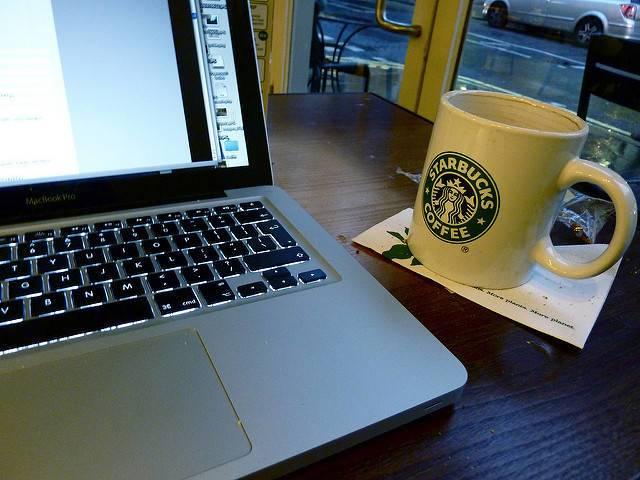

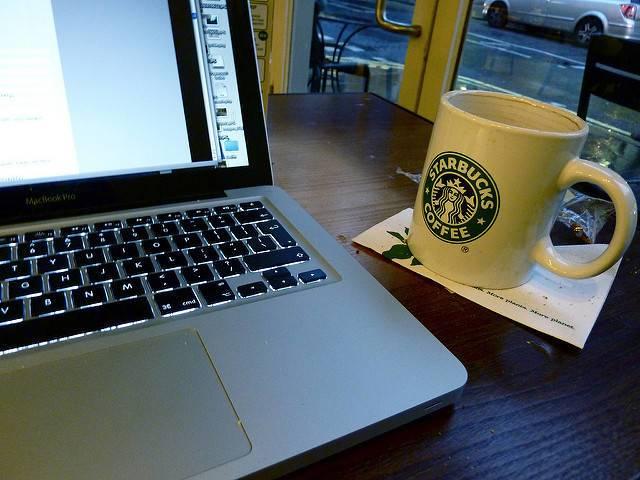

Starbucks, a company that is very committed to environmental sustainability, is an example of an organization that does a good job of encouraging employees to be brand advocates. They primarily do this by providing employees, who they call partners, with clear communication guidelines.

4. Partner with others

There’s tremendous power in numbers. Using your voice alone is one thing. Combining your voice with others in the community is another.

The New England Aquarium in Boston is a perfect example. The organization has long been committed to protecting the oceans, but has recently collaborated with local chefs, seafood providers, environmental groups, and ocean educators to enhance its “live blue” program.

5. Dive in deep

PepsiCo is another example of a company that does a nice job of communicating sustainability with external stakeholders. The brand has created a microsite that communicates the company’s ethos and provides a way of diving deeper into important topics.

As PepsiCo’s senior director of sustainability communications Erin Thomas explained, the goal of the site is to explore “issues which are important to the world and in which our company has a role to play a step further. Our aim is to create a dynamic digital user experience to discuss complex, pressing challenges and solutions, big and small.”

Effective Communication Matters

There is no substitute for effective communication when trying to extract maximum value from your investments in sustainability. You don’t have to feel bad about discussing the good you’re doing. Profitability is an integral part of the triple bottom line and clear communication is how you get there.

Jenna Cyprus is a freelance writer from Renton, Wash.

Image credit: Flickr / Magnus DWhat’s Possible When Science Isn’t Boring?

By Jeffrey Whitford

I often envy what the world looks like through the eyes of a child. Even the simplest things can make a child curious. This inquisitive mindset enables them to get lost in exploration without caring about what needs to get done, because the definition of “need” is different for a child.

Being able to revert to this child-like perspective ultimately led to one of the biggest “aha” moments that we in the Corporate Responsibility group at MilliporeSigma have had. We realized that perception and access are more than half of the battle when it comes to getting children interested in science, so we set out on a mission to try and solve that problem.

One of our team members had an idea that, at the time, seemed off-the-wall. He suggested painting a retrofitted shipping container bright yellow, adding in some additional vibrant colors and interesting shapes in the form of our own “microbes” to create a mobile science lab that could go anywhere. This mobility would allow students to freely engage with hands-on science—bringing access to those who would not have had this opportunity through their schools. This strange-looking, brightly-colored shipping container became MilliporeSigma’s Curiosity Cube.

Throughout 2017, the Curiosity Cube has made several stops around the country—and over the past month alone, it has traveled throughout Missouri and Wisconsin. Upcoming Curiosity Cube stops include Ohio, Pennsylvania and New Hampshire.

During the tour, we spend days, weeks or even a month in a city—sparking curiosity in the next generation of scientists and encouraging more of today’s youth to consider a career in science, technology, engineering and math (STEM). Through hands-on science experiments, students entering the Curiosity Cube can learn about DNA extraction, precision medicine and 3D printing right in their own community.

While a visually engaging exterior is the key to sparking interest, the most important part—the part that leaves a lasting impact—is having the right content, people and experiences inside the Curiosity Cube to not only capture the attention of children, but also to jumpstart their curiosity and empowerment. We partnered with Washington University’s Institute for School Partnership to map out experiences building on our popular Curiosity Labs program. Through Curiosity Labs, researched-based science lessons covering a variety of topics are conducted in classrooms by our own team of trained MilliporeSigma employees, who demonstrate that anyone can be a scientist, regardless of gender, ethnicity or race. We know that statistically, women and people of color are underrepresented in the sciences. If you ask children what they think a scientist looks like, the most frequent answer is “an old white guy with wild hair”—they’re imagining Albert Einstein instead of self-identifying. This limiting viewpoint thwarts us from potential discoveries, powerful collaborations and the opportunity for any child to pursue a dream because they don’t “see” themselves or anyone who looks like them as a scientist. Knowing this, our diverse group of employees uses opportunities such as our Curiosity Labs to connect with these children—ultimately helping to change their perspective and then self-identify as a future scientist.

By taking the lessons learned from our Curiosity Labs program and adding some extra bells and whistles to expose students to some of today’s most sophisticated technology, we’re able to help students connect problem-solving with the real world. Our team of scientists engages with students by sharing how the experiments in the Curiosity Cube are similar to what they do every day—connecting academia to industry, which is often a missing, critical element. The Curiosity Cube benefits not only the students, but also our own local staff, who volunteer their time and talents each day. Both employee engagement and pride in the workplace have increased as a result of the Curiosity Cube program and all of our employees said that they would volunteer again. One employee from our St. Louis team said, “The Curiosity Cube is the coolest project I've seen a company implement and I'm so happy to work here.” This speaks to not only the environment created, but what they’re seeing happen with the students that they work with.

We’re very interested in the meaningful learning happening inside the Curiosity Cube. While we realize that this short-term experience isn’t going to be like taking a year-long, middle school physical science class, we do want to track and measure what students are learning and taking away so that we can create the most meaningful experience possible.

Through our surveys of children following their experience, we’ve found that:

- 76 percent of students were able to answer the question “what does the cerebellum control” correctly

- 70 percent of students answered “what does DNA stand for” correctly

- 77 percent of students said they are now more interested in science

- 74 percent of students felt more curious following their Curiosity Cube

We’ve also had some great questions and “aha” moments from the students who have come through the cube. One fourth-grade student told us, “I just never realized how important science was until today!”

We view what we’re doing as an investment in the next era of STEM-capable problem solvers—those who will help to solve some of the world’s biggest challenges. From our founding membership in the STEMpact collaborative in St. Louis to the Sigma-Aldrich Science Partners program, which is now globally known as Curiosity Labs and our Curiosity Cube, we’re committed to helping educate the next generation of scientists—right here in the U.S. and abroad.

Who knows, maybe one of those problem solvers will have gotten their start in this strange-looking yellow shipping container.

Jeffrey Whitford is head of global corporate responsibility for MilliporeSigma.

Image credit: MilliporeSigma