The Human Equation: Using AI and Data To Address Global Challenges

Amen Ra Mashariki, the director for data strategies for the Bezos Earth Fund, discusses technology and climate action at the Impact Data Summit in New York City last month. (Image credit: Jane Chu/Mastercard Center for Inclusive Growth)

By Caroline Morris

How can we use new technology and collective action to significantly improve the lives of all people and the health of our planet? That was the central question at the recent second annual Impact Data Summit, hosted by the Mastercard Center for Inclusive Growth with the Rockefeller Foundation and Data.org, for social impact leaders.

Coinciding with the United Nations General Assembly meeting and Climate Week NYC, conversations at the summit looked at the current realities of data, artificial intelligence and social impact, their impact on the U.N. Sustainable Development Goals, the role of cross-sector collaboration to drive that impact, what the future holds for transformative technology, and how to make sure that future is sustainable, equitable and accessible.

“As leaders in data, we need to move fast and now, not tomorrow,” said Shamina Singh, the president and founder of the Mastercard Center for Inclusive Growth. “Don’t leave here without a new partnership, without a new plan, without a new program … AI, I hope you will think, means actionable impact.”

Here are the key takeaways that will define the future of data and AI.

AI can help the world meet its sustainability goals, with humans' help

Data and artificial intelligence (AI) have the potential to help achieve the 17 Sustainable Development Goals laid out by the U.N. in 2015 to jump-start improvements including climate action, gender equality and inclusive economic growth. “Digital technologies can actually help accelerate 70 percent of the SDG targets, which is quite incredible,” said Doreen Bogdan-Martin, secretary-general of International Telecommunication Union, the U.N. specialized agency for information and communication technologies. “Only 15 percent of the targets are on track.”

Her faith is grounded in the game-changing nature of AI. AI can interpret vast amounts of data that no human could ever process. And it can distill that data into something immediately actionable — a necessity as we race against the clock to solve these human crises.

At the same time, human beings must constantly scrutinize AI to understand what it’s saying and how it can help generate outcomes that help society and leave no one behind. The wrong outputs and outcomes “will only get amplified very quickly in this environment,” said JoAnn Stonier, the Mastercard fellow specializing in responsible AI and data. “As long as we have the accuracy, we have the right data, and we’re doing all of our homework, I do think we’re going to start seeing some amazing solutions," she added.

Innovating with guardrails

The internet was not based on a single piece of technology. Instead, its enduring power emerged when Bob Kahn and Vint Cerf — known as the “fathers of the internet” — invented the protocols and architecture that allowed computers to form networks with one another. “As long as the internet adhered to the basic architecture, it could continue to evolve,” Kahn said. That approach allowed the internet to persist and expand far beyond its first small network of computers.

For AI to make an impact, it will need a similar set of protocols and architecture to create interoperability on an international level.

Regulation will have a role to play, too. AI should be serving the communities in which it exists, and these needs vary widely depending on location, so regulation cannot be one-size-fits-all; it requires context to be effective. “Technology is extremely difficult to regulate for a number of reasons. It evolves very quickly. What you don't want is a static piece of regulation that is built based solely on the way the technology works today,” said Dorothy Chou, head of policy and public engagement at Google DeepMind. “Historically, what we've seen is that good regulation actually creates public trust.”

Together, we go far

When the COVID-19 pandemic hit, Kenya's government wanted to make informed decisions for the health and safety of its citizens, explained Shikoh Gitau, founder and CEO of Qhala, a Nairobi-based consultancy that specializes in health informatics and the technology of social impact. But every health center had its own small and private data silo, so policymakers were forced to follow frameworks created on other continents, which ultimately proved poorly suited to the needs of Kenya.

Information that’s fragmented by unnecessary barriers or delayed by bureaucracy loses its ability to make an impact. The way to change these limitations is through collaboration between the public and private sectors. As Holly Krambeck, director of development data partnership for the World Bank, said, “As much as I hate to admit it, international corporations can’t solve everything, so we need global partners of all different types.”

Drawing in and opening up

As of now, 85 percent of all AI developers are men, Gabriela Ramos, assistant director-general for the social and human sciences at UNESCO, said at the summit. And, as several panelists noted, the majority of data fed into AI comes from North America. That means AI models are being trained with data from a tiny sliver of the global population. In fact, there is almost no data representing the Global South at all — and if there is, it’s outdated and in incompatible formats.

These gaps in data and AI — as well as a lack of diversity among the data scientists — ultimately hurt everyone. For example, failing to represent women and people of color can produce inaccurate AI outcomes. Those oversights result in leaving millions of investment dollars on the table — money that could help drive resilience, economic growth and the physical wellbeing of entire communities. “You get out of data what you put into it,” Ramos said.

However, getting the most out of data and AI requires unraveling deep-seated, systemic issues. “We have to be mindful about not reproducing inequalities from the analog world into the digital,” said Lamia Kamal-Chaoui, the director of the OECD Center for Entrepreneurship , SMEs, Regions and Cities. This means investing in data collection in underrepresented areas, improving accessibility to such data, drawing diverse voices into the development of AI, and listening to the local communities where new technology will be placed to best serve their unique needs.

When it comes to developing digital technology, one of the most significant measurements is how it contributes to the improvement of human life. There may be a divide between better data and better decisions that will make a real difference in people’s lives, said Gina Lucarelli, team leader of the U.N. Development Program’s Accelerator Labs. “The real gems are the moments where you bridge that gap and you actually see data that drives decision-making.”

Caroline Morris is a contributor to Mastercard Center for Inclusive Growth.

This story was previously published by Mastercard Center for Inclusive Growth and the 3BL newsroom.

Biochar is a ‘Shovel-Ready’ Climate Solution, But Is It Ready to Scale?

Beau Burgess holds a clump of biochar at Blood, Sweat, and Food Farms in Homer, Alaska. (Image credit: Grist/Max Graham)

"This story was originally published by Grist. Sign up for Grist's weekly newsletter here."

When Beauregard Burgess and three friends decided to start a hog and poultry farm in 2015, they chose an odd location: 20 acres of swampy land on the east side of Homer, Alaska, a coastal hamlet south of Anchorage. The land, logged years ago, was in an industrial part of town, and its soil was in poor health. That anemia was part of the appeal for Burgess and his colleagues, who wanted to raise livestock in a way that would add nutrients and beneficial microbes to the ground, restore the local ecosystem, and improve the local food scene.

Today, Blood, Sweat, and Food Farms is something of an oasis. Its lush pastures are just down the road from auto shops, lots crowded with heavy equipment, and heaps of gravel. Burgess and his partners have turned the lot’s acidic, water-logged earth into a rich humus, and they’ve done so in an organic, regenerative way — that is, without synthetic chemicals. Such an achievement has involved a number of innovations and tactics, from building bioswales that limit flooding to spreading nutrient-rich compost across fields. But one tool in particular stands out: biochar — a jet-black substance made by roasting plant matter, like wood, in an oxygen-deprived environment.

The glorified charcoal is rare on American farms, yet it has become a focal point in the movement to turn agriculture into a climate solution. Biochar can lock up planet-warming carbon for hundreds, sometimes thousands of years, and unlike other, higher-tech technologies that suck carbon out of the air, it’s relatively straightforward and accessible.

“Look at the playing field. What else is out there that’s commercially viable right now?” said Kathleen Draper, board chair at the International Biochar Initiative. “The reality is: It’s a shovel-ready technology.”

As a result, Microsoft, JPMorgan Chase, Shopify, and other corporations trying to burnish their image as climate-conscious are paying biochar producers millions of dollars so that they can claim credit for the carbon that’s locked up in the soot and not in the atmosphere heating the Earth. Biochar now accounts for the vast majority of the carbon dioxide that has supposedly been removed from the air after being purchased by companies seeking to offset their planet-warming emissions, according to cdr.fyi, a website that tracks carbon removal data.

Still, it could be years before biochar fulfills its promise, if it ever does; only a small fraction of the amount that would meaningfully chip away at global emissions is currently being produced. And there’s no easy answer for how to scale it up.

Farmers have used charred plant matter for millennia to improve soils. In the Amazon rainforest, known for its nutrient-poor dirt, archeologists have dug up pockets of unusually dark, fecund earth, commonly referred to as terra preta. Those soils likely were made fertile thanks to intentional burning and the proliferation of a biochar-like substance thousands of years ago. The porous, spongelike material can act like a steroid for soil. It gives dirt structure, which helps bacteria and fungi latch onto it and make nutrients available for plants. And when it rains, biochar keeps soil from shedding off fields.

But that’s not why it has seen a resurgence in the United States. Two decades ago, when the world was awakening to the dangers of climate change, scientists became interested in the soil soot as a tool for carbon sequestration. The carbon that plants pull out of the air typically winds up back in the atmosphere, where it traps heat and warms the planet. Generally, plant matter either decomposes — say, as corn husks left in farm fields or food waste in a landfill — in which case microbes convert carbon into carbon dioxide; or it gets burned, sometimes for fuel or to get rid of waste wood.

Researchers have found that the process of turning wood, twigs, or leaves into biochar, through a procedure called pyrolysis, could turn about half of that matter’s original carbon content into a stable form that could stay in the ground for centuries. A study published in March in the Journal of Environmental Quality also found that using biochar, which helps keep nutrients like nitrogen in the ground, could cut planet-warming nitrous oxide emissions from agriculture by almost one-fifth.

“Our objective is to try to use biomass that would otherwise be rapidly decomposing [and] doesn’t have other utility,” said Charlotte Levy, a science advisor at Carbon180, a nonprofit that advocates for carbon removal. “One opportunity we see for that is to use corn stubble that gets left in the field.” The United States produces some 14 billion bushels of corn every year. Some of the husks, stems, and cobs left over could be turned into biochar and added back into the soil.

Burgess’s team at the farm in Alaska makes their biochar out of waste wood, rather than inedible corn parts, in a cylindrical steel tank the size of a small car. The wood comes from a local land-clearing company, co-owned by Burgess, that supplies logs that can’t be used for construction or firewood. “The things that end up as biochar on our farm were the things that could achieve no other higher purpose,” Burgess said.

Blood, Sweat, and Food has the capacity to roast wood into about 200 pounds of biochar each day. While they mainly mix the finished product with feed for their chickens and pigs, which do the work of spreading the char around fields by pooping it, they’re also starting to sell it to nurseries, greenhouses, and other farmers around Alaska, Burgess said.

Making biochar a global climate solution — the sort hoped for by the United Nations’ Intergovernmental Panel on Climate Change — will require producing it on a much larger scale. The amount of biochar being produced in the U.S. — 100,000 metric tons — is tiny compared to the amount needed to sequester carbon in a globally significant way. By one estimate, biochar could offset the equivalent of up to three gigatons of carbon dioxide each year by 2050. That’s roughly the same as shutting down 800 coal plants. To get there, producers would have to ramp up worldwide production drastically.

And even if producers do manage to ramp up production that much, there’s the risk that it would undo some of its benefits, particularly if the industry shifts to growing plants specifically for the purpose of making biochar. That could lead down a path paved by biofuels like corn ethanol, which has morphed into such a big business that much of the corn grown in the United States never ends up on dinner tables.

As soon as you start converting forests or fields into rows of crops with the aim of producing biochar, “you get into a lot more complicated questions,” said Levy. At that point, if you factor in the greenhouse gas emissions caused by the changes in land use (say, logging), then biochar may help worsen climate change, not solve it.

But the nascent industry isn’t anywhere near that point, Draper said. At the moment, she said, there’s enough plant waste already out there to make a dent in emissions without growing more crops. While there’s significant demand for biochar on the carbon market, industry proponents are trying to generate more interest among farmers and other businesses, like concrete companies that are adding the soot to asphalt to make their product less carbon-intensive or governments that could pour it into abandoned oil and gas wells.

There aren’t enough farmers actually using biochar to meet the demand generated by companies keen on buying the carbon credits associated with the charcoal. “The hiccup right now,” Draper said, “is that all of the investors want to know who’s buying the biochar and for how much.”

Part of the challenge is that biochar doesn’t exactly fit into the standard American farming curriculum. It’s neither a fertilizer nor a pesticide, and it doesn’t supercharge crop production. “It’s not something that’s likely to double yield,” said Milton McGiffen, a cooperative extension specialist and agricultural researcher at the University of California, Riverside. Still, McGiffen said, biochar’s benefits are clear, particularly when it’s added to soils that have a lot of sand or clay and struggle to hold onto water and nutrients.

Another challenge is that not all biochar is equal. How it’s made, and how it’s applied to soil, can affect how it works, said Rachel Seman-Varner, a soil scientist at the American Farmland Trust. “Biochar started to be promoted as a single solution and a silver bullet, and it’s much more nuanced than that,” she said. “A lot of people are trying to shift toward understanding that biochar is a class of products.”

Char made by roasting corn husks at 900 degrees Fahrenheit, for instance, won’t have the same properties as wood that’s broiled at 1,400 degrees F. Researchers at the U.S. Department of Agriculture are putting together a national database to help farmers choose from the many different types of biochar and connect them with local producers, and Congress is weighing legislation with bipartisan support — the Biochar Research Network Act — that would increase funding for similar research.

As proponents work to make the advantages of biochar more widely known to farmers, Burgess’s approach might offer some realism, and hope.

“For us, it’s not so much that biochar or pasture-based livestock or any of this is a panacea,” he said. It’s just a small way to limit waste, produce local food, and perhaps keep some carbon in the ground, too.

This article originally appeared in Grist. Grist is a nonprofit, independent media organization dedicated to telling stories of climate solutions and a just future. Learn more at Grist.org.

Coalition Connects Brands With Schools Struggling to Teach Sustainability

Students work together on an assignment about ecosystems and environmental impacts during a seventh-grade science class in December 2020. While more schools are introducing sustainability curriculum, some are struggling to get started. (Image credit: Allison Shelley for EDUimages via Flickr)

Elementary and secondary school teachers want to teach about sustainability, yet many lack the time, resources, and in particular, the tools to do so effectively. For those in the United States, help is on the way.

By 2030, the Sustainability Education Coalition aims to give more than 10 million K-12 students access to educational resources that will help them make informed decisions and take responsible actions when it comes to sustainability.

It’s a first-of-its-kind initiative aligned with the United Nations Sustainable Development Goals and launched by Discovery Education, a leader in developing digital content for K-12 teaching.

“The need for comprehensive sustainability education has never been more pressing,” Amy Nakamoto, Discovery Education’s general manager of social impact, said in a statement. “Recent statistics reveal a concerning trend: While the majority of teachers recognize the importance of teaching students about climate and sustainability, only half of them are currently addressing these vital topics within their classrooms.”

Three factors hinder teaching sustainability to K-12 students in the U.S., Natamoto said. First, some teachers have difficulty figuring out where classes on sustainability belong in their curricula.

“It could be in science classrooms, it could be in social studies classrooms, it could be in blended STEM [science, technology, engineering and math] classrooms. I think currently, teachers are having a hard time figuring out where it fits in the school day," Nakamoto told TriplePundit.

Others feel they do not know how to teach sustainability topics, she said. Teachers need and want more support in this area, according to a report from the Smithsonian Science Education Center. Of the teachers surveyed, 69 percent said professional development on sustainability would be helpful.

“They want to be able to talk about this with their students, but they don’t know how,” Nakamoto told us. Lastly, while school administrators believe sustainability is a critically important topic to teach, they don’t know how to get the resources to do so, she said.

The Sustainability Education Coalition aims to solve all three problems. It uses insight and expertise from partner companies to create digital content for students to learn from alongside the lessons on the Discovery Education Experience learning platform, Nakamoto said. Support is specifically focused on providing STEM and sustainability education resources to school districts that would struggle to access them otherwise.

“Another way the collaboration happens, in addition to the curriculum and the content, is through strategic thought leadership that takes educators and administrators and puts them in the same rooms as these leading companies,” Nakamoto said. “So [the companies] can understand the challenges of schools to talk about these topics, and the schools and administrators can understand how companies are wrestling with these topics in more real-time.”

On the other side, company partners benefit from joining the coalition through employee engagement, Nakamoto said. Employees want to see their companies investing in initiatives that align their corporate mission with a local community mission.

“Employee engagement is leveraging the employees of our partners to be part of the story. So, we are telling their stories, we are filming them and the solutions they’re doing,” Nakamoto said. “We deeply believe in showing the people who are the leaders in this movement to the students in classrooms across the U.S.”

So far, Subaru of America, LyondellBasell, Nucor, Honeywell, and the National Environmental Education Foundation have partnered with the coalition. Each company that joins helps to unlock access to a complete library of STEM and sustainability education resources for some critical communities, Nakamoto said.

“[Sustainability] is a topic that everybody is both wrestling with and evolving with at the same time,” she concluded. “We have a big vision to grow this to represent multiple sectors, multiple interests because the sustainability story is an everyday story that we all experience just walking through the world. In order to tell that story to students, we need to be influenced by all of the sectors that are engaged in sustainability at their corporate and community level.”

Patagonia's Search for a Better Wetsuit is What Sustainability Should Be

Surfer and Patagonia ambassador, Frank Soloman, surfs in a Patagonia wetsuit at Half Moon Bay in California. (Image: Fred Pompermayer)

The latest iteration of Patagonia wetsuits could change the way we think about outdoor gear. Made with sustainability, repairability and recyclability in mind, the brand's line of Yulex wetsuits launched this month represent a strong departure from the single-season neoprene version that dominates the market. The company isn’t gatekeeping, either. It’s hoping to encourage other manufacturers to follow suit.

The problem with wetsuits

“Conventional wetsuits are made with polychloroprene,” said Mackenzie Warner, a material developer at Patagonia. Also known as neoprene, the synthetic rubber pollutes waterways, languishes in landfills and never biodegrades. Worst of all, producing it creates cancer-causing chemicals that are devastating the community surrounding the only U.S. chloroprene manufacturer.

Wetsuits aren’t the only consumer item made from neoprene, nor is the chloroprene plant the only petrochemical factory releasing toxic chemicals in the Louisiana region known as Cancer Alley. But the outdoor industry’s contribution to a cancer rate that is 50 times higher than the national average is undeniable.

“No home in the community around [the] plant has been untouched by cancer,” Chris Nelson and Lewis Arnold, both surfers and journalists, wrote in Nordic Surfers Mag. With a population that is over 90 percent Black, the situation reeks of environmental racism.

A better rubber

Patagonia started designing wetsuits in 2008 and introduced the first suits made from Yulex eight years later. “As a brand, we wanted to get into wetsuits to show that it can be done in a better way … meaning less impact, less harmful material usage, and a better product in the long run,” Corey Simpson, communications manager at Patagonia, told TriplePundit. That upstream approach resulted in better repairability, functionality and durability for the user.

The company behind the Yulex material got its start by sourcing natural rubber from a desert plant called guayule. “I was actually working in a retail store here that was next to the headquarters. And this guy came in wearing a backpack and … takes out this huge blob of rubber. But it was clear rubber. It looked really clean. And he's like, ‘This is the future of your wetsuits,'” Simpson recounted. “That led us into our first natural rubber wetsuit. Since [then], it has just been a constant crank to get more refined materials and have higher and higher output with the least environmental impact as possible.”

That search for better materials led to the hevea tree, which can be tapped for its natural rubber. “That rubber is then purified to eliminate like 99 percent of the impurities and proteins and allergens that are in the natural rubber. And then, at the end of that process, you get what is called Yulex Pure,” Warner said.

The Yulex Pure material is Forest Stewardship Council certified, according to creator Yulex Corp. That means the forest the trees are grown in is responsibly managed to promote biodiversity and prevent deforestation while providing social and economic benefits.

Yulex natural rubber is not unique to the Patagonia brand. The company does not own a patent or the rights to the material. Rather, it's looking to encourage as many competitors as possible to make the switch to Yulex in the interest of sustainability. Another surf label, The Seea, also makes Yulex wetsuits and has since 2018.

“We understand that there's no other really clean supply chain. And we've spent so much time, energy, and money vetting this and really being able to scale the supply chain that it's like, ‘Hey, we've got this now, capitalize off of our leg work, please take this and then run with it,’” Simpson said. “Please utilize this technology, please use this supply chain.”

Beyond a single season

Between the sun, salt water and overall harsh conditions, most wetsuits are only designed to last through a single surf season. But Patagonia has taken a more sustainable approach to this, as well. “We really strive to have our wetsuits last for multiple seasons and years,” Warner said. “To do that, we want to put high-quality fabric on the interior and exterior lining.”

For now, that means continuing to use nylon in the lining of the wetsuits, which runs the risk of shedding microfibers. “With any fiber, of course, there's a concern of microplastics and we do our best to mitigate [that in] the construction of the net or the woven fabric,” she said.

All of the nylon that is used in Yulex wetsuits comes from post-consumer recycled material, but Warner said the brand will keep striving for more sustainable options. “As new technologies become available, we'd love to explore the use of different yarn types and different stretch fibers and all these different things,” she told us.

Another big difference between Patagonia’s Yulex suits and the average wetsuit is the ability to repair them, which is not typical. Not only have they been designed with repairability in mind, but there’s no cost to the consumer to get a suit repaired, aside from shipping charges.

“Our wetsuit team has repaired suits over and over for people where they're like, ‘Oh, I remember this suit.’ And they're rebuilding it again for its second and third life out there,” Simpson said. “It's just unheard of outside of our walls. It just doesn't exist, and our hope is that people see that value and understand … they can keep it in use longer.”

While the initial price point may be significant — starting at $100 for shirts and vests and over $450 for full suits — it’s worth it in the long run, especially because the suits significantly reduce environmental impact, he said. That impact is further reduced by the wetsuits’ recyclability. “We've found a way to enhance recycling techniques, to essentially turn our old wetsuits that are beyond repair into raw material that can then be used in new future products,” Warner said.

Setting a new standard

Patagonia is well known for its dedication to repair. As this extends into the realm of wetsuits, there is potential to influence other brands to move toward more sustainability in their own products.

As consumers come to terms with Earth’s finite resources, it’s imperative that clothing companies and outdoor gear makers encourage repairability along with recyclability and sustainable materials. If this can be done with wetsuits, surely it can be done with just about anything with the proper effort. And while cost remains a limitation for many people, the importance of long-term value can make a difference in how they spend their money. Brands that promote a business model of quality over quantity will ultimately do better for both consumers and the planet.

Advanced Technologies Are Essential to a Sustainable Future

It’s no secret that the adoption of advanced technologies is accelerating in agriculture and construction. Machines today are more powerful, precise and easy to use than they have ever been, making them more efficient, productive and sustainable.

Sustainability is top of mind for many businesses, and for agriculture and construction, it is an opportunity to transform how we manage our natural resources to grow food and build communities.

In real terms, that means finding innovative ways to reduce carbon emissions — in the plants where we build our machines and also during their usage — and developing methods to preserve the natural environment while maximizing productivity.

These challenges are familiar to CNH Industrial. Selin Tur, the company’s vice president of advanced technologies and innovations, and John Crowell, director of sustainability, explain how the industry is adopting and continuing to develop advanced technologies to find viable sustainability solutions.

How do advanced technologies play a role in achieving sustainability goals?

Selin Tur: All the technologies we work on have a sustainability impact, from automation and autonomous technologies to alternative fuels and electrification to advanced materials. That’s by increasing productivity, driving efficiency higher or reducing fuel consumption.

John Crowell: The path to achieving our sustainability goals is one of continuous improvement. Whether it be decarbonizing within our own operations, within our value chain or related to our product portfolio, it’s technology advancements that progress us forward.

What are the sustainability challenges that advanced technologies can help address?

ST: They can help reduce the carbon footprint of CNH Industrial and our products. Alternative powertrains, such as fully electric, hybrid electric and biofuels, are all viable solutions. They can reduce operations’ emissions while maintaining quality and productivity.

JC: There are further ways to meet the decarbonization challenge. We can manufacture our products with materials that have a lower emission impact for a higher level of recyclability, but also a higher level of end-of-life recyclability.

And precision technologies offer farmers innovative ways to lower their carbon footprint. Examples include improving water efficiency by using variable rate irrigation systems linked to real-time weather forecasts, which also take into account how the crop is growing. And pesticides can be applied precisely where they are needed.

Advanced technologies can also preserve biodiversity which considers the interconnectedness between water risk, water scarcity, climate change and ecosystem. Using precision technology to minimize inputs supports the natural environment and contributes to healthier soils.

What are some examples of advanced technologies addressing sustainability challenges?

ST: Recently we acquired ‘sense and act’ specialist Augmenta. A key solution the company offers is a multispectral camera and advanced artificial intelligence engine. This ‘sees’ the crop in front of the tractor and adjusts the fertilizer being applied in real time by visually measuring the crops’ nitrogen levels. This provides a new level of efficiency for farmers.

It optimizes inputs according to crop status and demand through precise rate control at normal vehicle speeds. This provides a new level of field efficiency for the producer.

At the end of the year, we’ll be launching the New Holland T4 Electric Power. It’s the industry’s first all-electric light utility tractor. With a battery pack that can support a full day of operation, it’s a viable alternative fuel solution for farmers looking to decarbonize.

It also adds to our growing electric product portfolio across agriculture and construction, which includes a series of mini excavators, a compact wheel loader and backhoe loader.

JC: Alongside electric, our work with Bennamann highlights a tried and tested biofuels solution. Bennamann has expertise in capturing, repurposing and storing fugitive methane emissions for energy use. And when connected with our machinery, they can dramatically reduce emissions to deliver a carbon-negative system that fully supports a circular economy. When electricity is generated from captured fugitive livestock methane, it can be used to power the tractor, the farm and even be sold back to the grid.

What are the significant challenges or opportunities regarding advanced technology adoption?

JC: One adoption challenge around decarbonization is ensuring that the alternative fuel equipment can complete all the tasks on the farm. That’s why biomethane is such an attractive solution – it delivers the same power as a conventional diesel machine.

Another challenge is variety in what our customers are aiming to produce. Because of this, there's a great degree of variability in the solutions they're looking for. They want to be sustainable, but all want to maximize their productivity. And to satisfy this, we continually evaluate our portfolio.

ST: For customers, price and availability are key. Installing and operating advanced technologies must come close to their current total cost of ownership and provide a significant return on investment. As accessibility to these fuels increases, so should the variety of equipment that can utilize them.

JC: Indeed, there is still an infrastructure challenge — whether that be recharging/fueling stations or biodigesters. Training and support, both for operators and our dealer partners, will also be needed to ensure a smooth transition to these new solutions.

What promising technology advancements hold potential for sustainable agriculture and construction?

ST: Certainly, artificial intelligence and machine learning technologies. Advanced sensors will make farming practices more efficient by controlling the volume of chemicals applied to fields.

We’re also working on augmented and virtual reality. These solutions also accelerate product development times through virtual assembly and digital prototyping — and they can reduce our travel by enabling us to conduct virtual design reviews. It’s sustainability through reduction. They also enable remote diagnostics and mean field issues can be resolved quickly without having to wait for a technician to attend.

JC: There is also an increasing focus on electrifying implements and not just the vehicle. There's a great opportunity there for further innovation, leading to increased productivity and sustainability.

What does future collaboration between your technology and sustainability functions look like?

JC: It's a collaborative engagement between our teams. We both acknowledge the challenge of decarbonizing our products, but also the opportunity for the industry, and for our customers.

The sustainability team is leading the efforts to help the company meet the Paris Climate Agreement’s objectives. And in doing so, we are learning from the research and development team. They’re showing us what’s feasible, what's within their technology innovation roadmap and what really matters to our customers.

ST: My team is in an advantageous position working with John. It enables us to tie our innovation and technology programs into company sustainability goals and targets. It’s a good process that has real customer benefits.

--

With CNH Industrial continuing to innovate, the agriculture and construction industries are progressing toward a more sustainable future. It’s clear that advanced technologies are more than just an option — they’re essential. We are committed to delivering solutions that produce food, fiber, energy, shelter and infrastructure for a growing world population sustainably.

And that does not mean sacrifice. In fact, it’s quite the opposite. Advanced technologies are unlocking new ways for operators to add value, from a sustainability standpoint and beyond.

This article series is sponsored by CNH Industrial and produced by the TriplePundit editorial team.

Image credit: Valentin Valkov via Adobe Stock

How Brands Can Help Get Out the Vote in the U.S.

Co-hosted by The Body Shop and HeadCount, a voter registration event held in Washington Square Park on Sept. 17 rallied hundreds of people to get registered or check their registration status.

Voter engagement is on the rise across the United States, with the elections of 2018, 2020 and 2022 breaking records for high turnout. But around a third of eligible U.S. voters — more than 50 million people — are still not registered to vote. Importantly, young people (those aged 18 to 25) are less likely to be registered. Earlier this month, activists, nonprofits and brands across the country marked National Voter Registration Day with engagement campaigns aimed at getting more people set up to head to the polls in November.

The observance day has proven a success since it first launched in 2012, with organizers reporting more than 5 million people registered to vote on the holiday over the past decade. In New York City on the sidelines of Climate Week and the U.N. General Assembly, brands including The Body Shop, Tony's Chocolonely and Partake Cookies joined civic organizers like HeadCount, Democracy NYC and NYU Votes for a registration event in Washington Square Park, where nearly 750 people registered to vote or checked their voter registration status.

Hundreds of similar activations took place across the U.S., but with the 2023 midterm elections approaching and a pivotal presidential election in 2024, this work is just beginning. So, what's still needed to get more folks registered, and how can brands keep the momentum going?

Reaching young people: A critically underrepresented demographic for voter registration

Talking heads on TV news often paint a picture of apathetic young people who can't be bothered to show up at the polls. But have you ever stopped to think about why more young people don't vote?

"We know that a disproportionately low percentage of young people are represented in government," said Hilary Lloyd, vice president of marketing and corporate responsibility for The Body Shop North America. "So then it follows that a disproportionately low percentage of young people's preferences or the issues they have passion for are represented in government."

Indeed, the median age is 57.9 years in the U.S. House of Representatives and 65.3 years in the U.S. Senate. Just three U.S. senators and 16 House members are under the age of 40.

With this in mind, it's less a matter of getting folks in their teens and 20s to put down the TikTok and head to the ballot box, and more about helping young people see themselves and the issues they care about represented in the public sector. On this front, state and local elections provide a vital proving ground, with a growing number of young people throwing their hats in the ring for public office. The November elections offer an actionable opportunity for their peers to get registered and support them.

"The more folks we can get engaged in civics early, the more likely we can get more representation for young people and the issues that young people are passionate about in political discourse across the U.S.," Lloyd said.

Brands show up and show out for National Voter Registration Day

The Body Shop asked young people about those issues at the event it hosted with the youth voter registration organization HeadCount in Washington Square Park. "We hosted a customer engagement activity, asking folks who participated in the event to tell us what they're voting for, to put forward in people's minds what's important to them as we get into election season," Lloyd said.

Around 500 participants named issues ranging from LGBTQ+ and women's rights to climate justice, education and Social Security. Young organizers including Deja Foxx, a 23-year-old reproductive rights activist and founder of Gen Z Girl Gang, and Genesis Butler, a teen animal rights advocate and founder of Youth Climate Save, were in attendance helping to get people registered to vote. "It makes sense for young people to encourage young people to get involved in public discourse and democracy," Lloyd said.

The Body Shop hosted smaller events at retail stores across the U.S. and leveraged its e-commerce and social media platforms to get people registered. On an ongoing basis, shoppers can scan a QR code at "Act," or activism, Stations in The Body Shop stores to register to vote straight from their phones.

HeadCount's efforts with The Body Shop and other companies like Monumental Sports and Entertainment and Major League Baseball helped the organization register more than 16,000 voters this year, Lloyd said.

How to keep the momentum going on voter registration

The Body Shop's voter registration campaign is part of a broader effort called Be Seen, Be Heard, which launched last year with the aim of getting more young people involved in public life. The campaign takes the form of partnership with groups like HeadCount and activists like Foxx and Butler, who will continue to partner with the company to drive voter registration on social media in the lead-up to 2024.

Beyond the U.S., Be Seen, Be Heard is global — and early outcomes from the campaign show what's possible when brands put concerted effort into engaging young people in the electoral process.

The campaign reached approximately 51 million people online in its first year, gathering more than 90,000 signatures on petitions related to key issues in countries around the world, according to the company. In Canada, store managers helped rally nearly 13,000 signatures in support of moving federal elections to the weekend so more young people can make the time to vote. In Malaysia, the company and its supporters successfully pressured the government to honor their commitment to lower the voting age from 21 to 18. In New Zealand, The Body Shop’s partner Make It 16 won a supreme court case which found the country's current voting age of 18 to be inconsistent with its bill of rights.

"Some really remarkable movements have taken place," Lloyd said. "We want to move people through petitioning government or petitioning for legislative change, which creates real, fundamental, systemic change."

While global civic activations may be out of reach for some companies, voter registration groups like HeadCount, Rock the Vote and NextGen America make it easy for any brand to get involved by hosting registration pages on their websites and spreading the word among their customers. Meanwhile organizations like Time to Vote are calling on companies to commit to give their employees paid time off to cast their ballots on election day.

"Be a facilitator for voter registration," Lloyd recommended to other business leaders. "Use your reach, use your platforms — both your retail and digital presences — to drive voter registration. Partner with folks like HeadCount or organizations who do the same."

It really can be as simple as sharing a post on social media, as the queen of summer Taylor Swift proved when her recent Instagram post drove a 1,226 percent jump in participation on the voter registration site Vote.org. Considering nearly half of U.S. states have recently passed legislation that makes it harder for people to vote — including changes to registration laws and polling locations — efforts like these are sorely needed, and certainly far from over.

Get more coverage like this in TriplePundit's weekly Brands Taking Stands newsletter. Sign up here for new stories every Wednesday.

Images courtesy of The Body Shop

Buildings: The Unsung Hero of Public Health

As the world contends with the rise of acute public health threats and the devastating impacts of climate change, we teamed up with five former surgeons general and a number of executives from leading public health organizations to turn the attention of policymakers to an unsung hero: our buildings. That’s right, our buildings play a pivotal role in our well-being, and it’s time our policymakers recognize this.

Buildings shape our health outcomes in profound ways. For example, health benefits from better indoor environments could lead to annual economic gains of $200 billion. Indoor ventilation enhancements could improve cognitive functions by up to 101 percent, translating to a per-person productivity benefit of up to $7,500 per year. Despite these numbers, most policymakers fail to focus on buildings, the spaces and places where we spend about 90 percent of our lives.

In addition to supporting our health, our buildings can also be a bulwark against climate change. As we face intensifying impacts from an already changing climate, buildings that are fortified for health can serve as literal and metaphorical shelters from the storm. They can be designed to counter health threats like extreme heat and flooding while also enhancing our productivity, our comfort and our quality of life. By taking a comprehensive approach, our buildings can prioritize health-resilience focus areas such as indoor air quality, water quality and management, thermal comfort, emergency planning, integrative design, healthy and sustainable materials, healthy lighting environments and food security.

As a case in point, look more closely at just one of these strategy areas: enhancing indoor air quality. Clean indoor air — which requires a series of interdependent strategies across mechanical ventilation, air source control and filtration — is critically important when fortifying indoor environments against well-known climate impacts, including increased ground-level ozone pollution and increased smoke pollution from wildfires, which emit fine particles and in turn increase the risk of adverse chronic and acute cardiovascular and respiratory health outcomes. But there are also increased indoor air quality concerns from rising temperatures, more intense precipitation patterns, and increasing concentrations of atmospheric carbon dioxide. Each of these can contribute to considerably higher levels of certain airborne allergens, which can produce increases in asthma episodes and other allergic illnesses.

Yet many of the same healthy building strategies that can protect us against climate change have also been scientifically proven to help with everything from combating obesity to improving our sleep, from lowering the risk of heart disease to reducing respiratory illnesses and the spread of communicable diseases.

A seminal, peer-reviewed study published last year in the journal Building and Environment found that buildings certified to the WELL Building Standard helped improve worker satisfaction by 28 percent, well-being by 26 percent, mental health scores by 10 percent and productivity by 10 median points.

Those results are part of a growing body of research linking healthier spaces to reduced employee absenteeism, improved cognitive function, and lower healthcare costs for companies, as well as stronger real estate financial returns from rental premiums and longer lease terms.

But we can’t forget how the COVID-19 pandemic exposed glaring gaps in building policy, specifically related to ventilation and indoor air quality. Rather than acting as shields against the virus, all too many of our buildings were ill-prepared to protect us.

As we anticipate future challenges, the argument for health-driven building policy has never been stronger. Fortunately, we’re beginning to see some new legislative ideas that are designed to accelerate healthy building improvements. For example, in the last few years, several bills were introduced to the U.S. Congress that would provide businesses with tax incentives to deploy solutions that help improve indoor environmental quality. The Joe Biden administration too has made noticeable efforts to push for healthy buildings, hosting the first-ever White House Summit on Indoor Air Quality last year.

Public investment in buildings is a huge policy opportunity. Over the next decade, federal, state and local governments will invest hundreds of billions of dollars in our nation’s buildings, spanning considerable funding for affordable housing, federal buildings and schools, and long-term, multi-billion-dollar incentives for the decarbonization of residential and commercial buildings.

The pivotal question for policymakers is whether these investments will also prioritize the people inside, and in doing so, improve public health outcomes. To ensure that’s the case, our decision-makers need to rethink our current building policy framework by elevating health.

A good start would be incentivizing solutions to increase ventilation performance, improve indoor air quality, adopt emergency preparedness plans and support healthy, sustainable materials. We need policymakers to see buildings not just as structures that contain us, but as pillars that uphold our nation’s public health.

Image credits: Abigail Keenan and Robert Bye via Unsplash

ESG Concerns Heat Up in Food and Beverage Supply Chains: Can 2D Barcodes Help?

We know many consumers consider ESG (environmental, social and governance) concerns when making a purchase. 2D barcodes like QR codes offer a seamless way for brands to share relevant information about where a product came from and how it was made, helping their offerings stand out among the competition.

Environmental, social and corporate governance (ESG) concerns are at the forefront of consumers’ minds when they make purchasing decisions today. With recent reports disclosing human rights risks lurking within food and beverage supply chains — and 37 percent of brands having yet to share how they’re evaluating them — consumers are calling for increased transparency, forcing companies to take a closer look at their existing business practices.

Unrooting forced labor and ESG challenges

An estimated 27.6 million people are in forced labor today, ranging from deceptive recruiting and debt bondage to unsafe working conditions and excessive work hours, and 12 percent of them are children. These exploitative practices frequently occur when farming high-risk commodities including fish, beans, cattle, coffee, rice, tea, tomatoes and wheat. Food and beverage companies are fighting back, placing increased scrutiny on these products’ suppliers and canceling contracts with those who are unable to comply with ESG policies. But unrooting forced labor is easier said than done.

The food and beverage industry relies on an intricate network of suppliers and trading partners to facilitate the movement of goods from origin to destination. Our favorite brands often work with thousands of suppliers both domestically and internationally in countries across Europe, Asia and Africa. With expansive supply chains, varying reporting requirements across regions, and resource constraints, it is often difficult to trace ingredients back to their original source and gain adequate visibility into every supplier. These challenges, compounded with a lack of widespread structure for corporate ESG accounting, can allow human rights violations to go unchecked.

How to nurture ESG success

According to the Business and Human Rights Resource Center’s latest analysis, two organizations are navigating ESG better than the rest: Tesco and Woolworths. The companies scored a 52 and 56 on their human rights evaluations compared to the industry average of 16. Tesco, one of the world’s largest multinational retailers with over 3,600 stores in the U.K. alone, requires primary, or first-tier, suppliers in high-risk regions to undergo human rights audits prior to supplying their stores, and submit to additional audits on an annual basis after onboarding. In 2022, the company canceled 28 supplier sites, and temporarily suspended 57 others, due to human rights concerns.

Woolworths, Australia’s largest retailer with 1,261 stores and 18,270 direct suppliers, sources 97 percent of its fresh fruit and vegetables and 100 percent of its meat from Australian farmers and growers. During onboarding, suppliers are segmented based on their risk categories — the higher the risk, the more frequently they’re audited. The company’s non-conformances tied to safety have decreased by 10 percent year over year.

Planting the seed for industry transparency

There are innovative changes on the horizon for food and beverage companies that will increase the visibility and transparency around production processes with partners and consumers. This is especially critical amid the current era of rampant greenwashing, as buyers demand to know their favorite brands are living up to their ethical and sustainable production claims.

To improve consumer transparency, trust and brand loyalty, food and beverage companies are starting to implement an increasingly well-adopted technology: two-dimensional (2D) barcodes.

2D barcodes: What they are and what they mean for ESG

In an initiative known as Sunrise 2027, being facilitated by GS1 U.S., the industry is migrating from the standard UPC barcode – found on consumer packages for almost 50 years — to a 2D barcode.

While 2D barcodes may sound unfamiliar (and futuristic), the technology is more common (and accessible) than you might think. Compared to one-dimensional barcodes (such as the UPC that is used for price lookup to automate checkout), which store information horizontally and can only contain up to a few dozen characters, two-dimensional (or, 2D) barcodes store information horizontally and vertically. This enables 2D codes, such as QR codes, to fit thousands of characters of data, from product batch/lot numbers to URLs.

On top of allowing for enhanced data storage, 2D codes were designed to be easily scanned by smartphones and other imaging devices, allowing for ease-of-use in addition to enabling enhanced information sharing.

2D barcodes will soon give consumers greater visibility into the origins of the products they buy, amongst other use cases. They allow brands to share information on where a product was grown, the factory it was processed in, and the sustainability practices of the company that made it — all while still going “beep” at point-of-sale.

While the retail industry has committed to implementing 2D barcodes over the next four years, some prominent food and beverage brands already use them. Woolworths uses 2D codes to connect business partners across the supply chain with the data they need for inventory management, traceability programs and sustainability initiatives. By early 2022, 2D barcodes were on 50 percent of products in Woolworths’ meat range across more than 1,000 stores. In the future, Woolworths and its suppliers also plan to make their products' sustainability information and certifications — down to the crop and serial number — as well as harvest information (i.e., farm map, pack date, production processes) and recycling instructions readily available to consumers.

The food and beverage industry is in the middle of a pivotal change where transparency is becoming the norm and responsible business practices will dictate growth. By ensuring accountability on ESG compliance now and opening the lines of communication with consumers, food and beverage brands will not only safeguard their own future, but also contribute to a more equitable and sustainable global economy.

Solving the Wind Industry's Waste Problem

Wind power is an increasingly important part of the energy mix as the world works to counter the climate crisis. But with first-generation wind turbines reaching end-of-life, questions loom over how to properly handle the waste they create. While wind turbines are up to 90 percent recyclable, turbine blades in particular present the biggest challenge.

The challenge of recycling decommissioned wind turbines

This is especially true as more wind power comes online. It accounted for 22 percent of all new electricity capacity installed in the United States in 2022, according to the Department of Energy, while also being one of the lowest-cost sources of electricity in America. The sector is poised for rapid growth, attracting $12 billion in capital investment last year alone, according to the DOE.

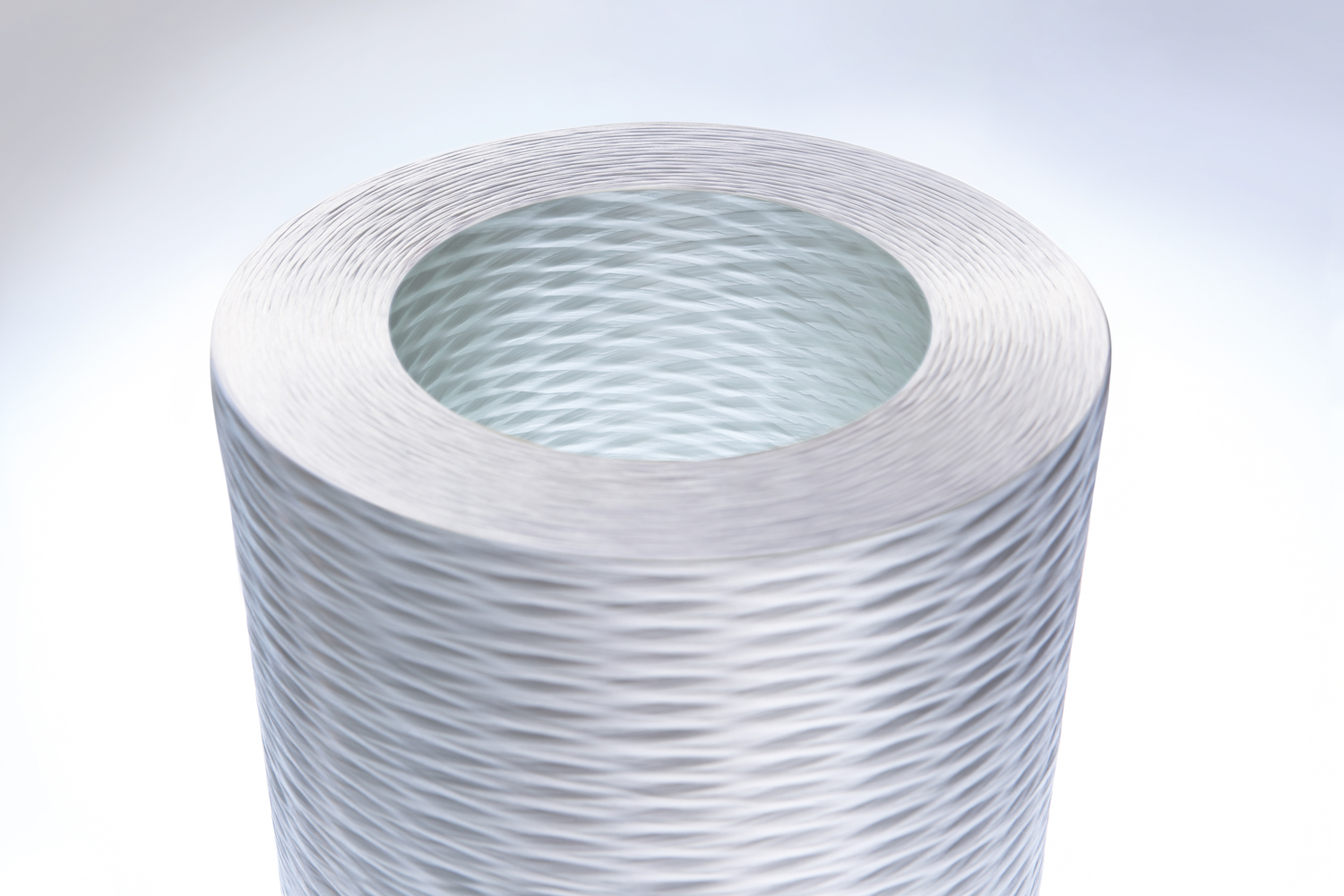

Undoubtedly, it’s great news that this renewable source is increasing its share. But if we don’t find a way to manage wind turbine blade waste, up to 2.2 million metric tons worth will accumulate in U.S. landfills by 2050, Owens Corning, a manufacturer of glass fibers that are used in the composite materials for wind turbine blades, detailed in its 2022 sustainability report.

The company’s leadership recognizes this is unsustainable, and as a major global supplier to wind turbine manufacturers, Owens Corning is greatly invested with other industry partners in figuring out the best ways to handle retired turbine blades.

After all, "wind is a critical technology for reducing emissions," Patrick Sullivan, strategy director for the composites business at Owens Corning, told us. Somewhat ironically, as wind turbines have become more efficient at making electricity, recycling their blades has become more problematic.

That’s because achieving greater efficiency means modern turbines are designed with much longer blades than those used in first-generation types. “To harness the maximum kinetic energy from the wind, you want as long of a blade as possible to increase the rotor diameter,” Sullivan said. “To have such long structures that support themselves and face various forces over 30 years, it needs to be strong and lightweight. So, that switches you from traditional metals and woods to more advanced composite materials.”

Therein lies the problem. Whereas steel and alloys are mono-materials that are relatively easy to recycle, composites are not. “Blades are designed to last a long time, and the fundamental nature of a composite is you are combining dissimilar materials together that are not designed to come apart,” Sullivan explained.

What’s in a wind turbine blade, anyway?

Should you be wondering, a composite wind turbine blade is made from a mix of glass and carbon fibers, which are combined with resins and plastic polymers. These materials wrap a structural core material which might be made of balsa wood or PET plastic foam.

A blade made today is designed to be in service for about 30 years, but the in-service time could be cut short because of turbine efficiency improvements. This means asset owners might elect to retire older turbines, which generate less electricity, in favor of newer and more efficient ones.

“An average turbine is in the 3- to 5-megawatt range,” enough to power 3,000 to 6,000 homes, Sullivan said. “Ten years ago, it might have been a 1-megawatt model,” he told us. As a result, a given area of wind farm can generate far more power today, incentivizing turbine upgrades, or “re-powering” as it’s known in the industry.

Consequently, many old turbines are being taken out of service before they fail, meaning the waste is already piling up. This creates urgency to address the landfill problem today, while the problem will only continue to compound in the future.

How to recycle a wind turbine blade

So, what to do with a retired wind turbine blade that needs to be kept out of landfill? Options range from the very low-tech, to higher-order processing which is more desirable.

Let’s start with the low-tech options. Landfilling blades is already banned in some parts of Europe. Advocates are pushing for a full ban across the continent, with a similar movement growing in the U.S. While this is stimulating a range of efforts for effectively dealing with the problem, at the most basic level it has involved taking blades, shredding them up and burning them in cement kilns as a power source. That’s not ideal, and the only real reason to recommend disposal by such means is that it avoids landfill. Rather than burn them, some wind farm operators have opted to store their blades until viable solutions are found.

“An improvement from cement kilns could be mechanically breaking down the blades and either compounding the remnants into pellets, which can be molded into new composites, or using the fractions in other composite parts,” Sullivan said. “The challenge is parts made with these pellets, for example, will have lower performance than virgin fiber composites. This really starts to limit the pool of use opportunities, as composites are advanced materials in higher demanding applications.” Nonetheless, Owens Corning has been able to provide materials from pellets which have gone into things such as decking materials or railroad ties.

Other novel uses are interesting, too. “People are designing bridges out of old blades,” Sullivan told us. “They are cool projects, but there are thousands of blades in the world,” he said, with the implication that there are simply not enough projects to use all decommissioned blades in creative ways like this.

Instead, Owens Corning sees the greatest potential in taking a materials science approach. “How can we separate the fibers away from the resins?” Sullivan posited. “And what can we do with these fibers in a second life?”

To this end, the company is working with other partners to experiment with recycling processes such as pyrolysis. In very simple terms, pyrolysis involves a process of heating blade material to very high temperatures in the absence of oxygen, leading to a physical separation of materials at the molecular level.

““It has been proven at lab-scale: You can take blade waste through a pyrolysis process and separate glass fiber from the resin systems, and we can take those fibers back,” Sullivan said. This method of recycling avoids downcycling, as recovered glass fibers can be melted down and reused in place of virgin material. “We would love to be able to get the fibers back from that type of process, and our partners from the chemical industry I assume would love to get their polymers back, too.”

But making this commercially viable and cost-effective at scale remains a challenge. That’s in large part because making virgin glass “is relatively very low-cost,” Sullivan said. “The efforts to reduce the cost of wind energy over the past two decades have also trickled down to reduce the cost of glass fibers tremendously,” he added. Energy inputs for pyrolysis need to be considered, too, and Sullivan suggested electrification and green hydrogen might be ways to mitigate the impact of the pyrolysis process in the future.

The future of wind turbine blade recycling is collaborative

Challenges aside, recycling blade waste will become increasingly urgent and indeed a business imperative going forward. “We will be one of the companies to develop circular models. We see it as a huge competitive advantage,” Sullivan said.

Nevertheless, it will take a combined effort. Owens Corning is part of a consortium of companies in the European-based Zebra project, which has a goal of developing the first 100 percent recyclable wind turbine blade. "Part of this effort is to produce blades with zero-waste and design the composite for recyclability, making it easier to disaggregate materials at end-of-life,” Sullivan said.

In addition Owens Corning joined the U.K.-based SusWind project, a consortium of companies launched in 2021 to “facilitate the recyclability of existing blade technologies, drive the use of more sustainable materials and processes, and develop new approaches based on circular design principles,” Sullivan said.

As the wind industry moves toward greater sustainability from end to end, Owens Corning’s efforts are ongoing, too. “We can make a major impact to the wind industry in helping tackle this challenge,” Sullivan said. “The goal is to take that fiber back and deliver recycled content fibers to build high-performing composites.”

Image credit: Thomas Reaubourg/Unsplash and Owens Corning

This article series is sponsored by Owens Corning and produced by the TriplePundit editorial team.

Images courtesy of Owens Corning

Innovating Across the Aisle Solves Social Issues

Social entrepreneurs play a vital role in developing innovative approaches to address pressing social issues. Public policy designed to further this work can help push progress forward faster, experts say.

“Policy can hold social innovation back if we just keep funding the same programs over and over again without asking whether the programs are actually effective, and are they actually achieving the desired results for those who need them most,” said Deborah Smolover, managing partner of New Profit and executive director of America Forward.

America Forward, a nonpartisan initiative of the venture philanthropy fund New Profit, works to help social entrepreneurs and policymakers find common ground and shape legislation that encourages the creation of effective and equitable solutions.

Government funding “enormously outweighs and exceeds” private funding for social and human services, so how the government allocates that funding is critically important, Smolover said.

Further, policy can hinder social innovation if it’s focused on outputs rather than outcomes. For example, if a workforce development or economic mobility program measures the number of graduates but doesn’t measure outcomes — such as whether those graduates land good-paying jobs that enable them to improve their living conditions — it becomes difficult to measure the program’s effectiveness and the impact of the government funding.

“We believe that these leaders who are closest to communities and who are closest to the problems have deep expertise, and utilizing that expertise to craft programs and policy solutions can vastly improve public policy,” Smolover said. “Put simply, they know what works, and the power of this expertise is greatest when social innovators collaborate with one another in communities to create policy solutions together.”

America Forward’s creation is rooted in comments by former White House advisor David Gergen, who served in the administrations of presidents from both major parties. Gergen said the potential impact of social entrepreneurs was deterred because the people who were “deeply invested” in effecting social change were overlooking the policies and systems in which their work happened.

“Essentially, by not engaging with government, social entrepreneurs were missing an enormous opportunity for impact, and this really resonated with our social innovation community,” Smolover said. “What I think we’re seeing now is more and more social innovation, and organizations are really interested in policy and advocacy work.”

Since its inception about 15 years ago, America Forward grew into a coalition of more than 120 social innovation organizations reaching 9 million people in more than 15,000 communities nationwide. To date, the America Forward network has leveraged nearly $2 billion and directed millions of federal resources toward programs that are achieving measurable results for those who need them most.

In recent years, nonprofit organizations have slowed their lobbying of policymakers, Smolover said. That's not because lobbying is viewed as less important, but because many nonprofits lack the necessary resources and access to advocacy, training, support and tools.

“That is why we believe our work at the America Forward Coalition is so vitally important and so valued among our social entrepreneurs because, by advocating together, they’re both more powerful and more efficient,” Smolover said. “We have tried to meet that need by offering more trainings through our America Forward Advocacy Institute, which is basically designed to help social entrepreneurs become better, bolder advocates.”

The institute saw a record number of requests for training in this past year, she said. The exceedingly polarized political landscape in the U.S. highlights the urgency of finding common ground to address social problems.

“We are a non-partisan initiative seeking bipartisan policy solutions with a team that is very diverse along many dimensions, including prior experience working on both sides of the aisle,” Smolover said. “We know that to get policy passed, we need to be able to cultivate a diverse group of champions across many different ideologies and political points of view. We’ve been able to do that time and time again in every administration, in every Congress, with varying makeups.”

America Forward’s successes include spearheading the creation of the Social Impact Partnerships to Pay for Results Act, a $100 million pay-for-success demonstration fund administered by the Department of the Treasury. It invests in innovative state and local partnerships that compensate providers on the basis of measurable improvements in people’s lives, from expanding workers’ earnings to reducing child abuse and neglect.

The coalition was also instrumental in the creation of the Social Innovation Fund, which invested more than $400 million in locally driven, evidence-based innovations in partnership with intermediaries across the nation.

Now, America Forward is working with representatives on both sides of the aisle to generate support for key provisions of those bills, the Workforce Development Innovation Fund, and the RESET for America’s Future Act, in larger reauthorizations that are moving forward.

“It’s not that every mentoring organization or economic mobility organization has the same viewpoint or has the same proposed solution,” Smolover said. “We’ve become very adept at working with different viewpoints within our coalition. And then, working to find not the least common denominator, but those sets of common principles that all of our organizations can agree on, and come up with a narrative that we feel can reach leaders of varying political ideologies.”

Image credit: Ian Hutchinson/Unsplash