Mars to collaborate with Tata Trusts on food safety in India

Food giant Mars and Tata Trusts, the philanthropic coalition, have entered into a Memorandum of Understanding (MOU) to work together to advance agriculture development, address malnutrition, and improve food safety in India.

Looking to develop methods and tools to increase crop productivity, farm income, and sustainability of select agriculture commodities, the two organisations will also conduct joint research on nutritional guidelines that can help address anemia and other forms of malnutrition.

Mars and the Tata Trusts also plan to collaborate on reducing Aflatoxin contamination in India’s supply chain. Aflatoxin – a naturally occurring, poisonous chemical produced by certain molds – is a critical food safety issue in India.

“The Memorandum of Understanding with the Tata Trusts is an important step in Mars’ journey to improve nutrition, food safety, and sustainability in India,” said Fiona Dawson, president of Mars Food (pictured above). “Tata Trusts’ strong commitment to improving the quality of life in India, and the depth and breadth of their expertise, makes them a natural partner for Mars.”

Pictured above: Fiona Dawson, president of Mars Food and Ratan Tata, chairman of the Tata Trusts signing the MOU.

California Declares State of Emergency Over LA Methane Leak

Two and a half months after a gas leak at the Aliso Canyon Storage Facility in the San Fernando Valley started, and still has not been stopped, California Gov. Jerry Brown has declared a state of emergency. Residents have long been complaining of illness, and thousands of people have relocated from the vicinity of Porter Ranch, California, located about 30 miles (48 kilometers) northwest of downtown Los Angeles.

The Porter Ranch gas leak has been one of the worst disasters to hit Southern California in the past several decades, with its long-term outlook still unknown. Fumes from the leaking wells have caused many residents to complain about a range of illnesses including headaches, nosebleeds, nausea and dizziness. For many families living in the region, frustration over what they perceive as a slow response to the leak has turned into exasperation.

“It’s the BP spill on land,” activist Erin Brockovich has said on CNN, and judging by the evidence, Brockovich is hardly exaggerating. According to the Environmental Defense Fund (EDF), one NGO taking the lead on monitoring the Porter Ranch gas leak, this disaster demonstrates why more oversight of natural gas storage facilities is needed. EDF claims that the Aliso Canyon Storage Facility, the largest such natural gas storage unit west of the Mississippi River, is spouting 62 million cubic feet (17.5 million cubic meters) of methane gas into the atmosphere each day.

That methane gas, insist EDF activists, will have a massive impact on the regional environment. EDF has launched a digital counter that is tabulating the amount of gas the Aliso Canyon facility is leaking. EDF says the amount of gas leaked has the equivalent climate impact of driving 7 million cars a day. Meanwhile EDF has released photographs depicting the damage that has occurred at Aliso Canyon as well as photographs using technology that shows the size and breadth of the spill — which looks like an ongoing volcanic eruption.

Southern California Gas Co., which owns the Aliso Canyon Storage Facility, has said repairs in the well will not be completed until February or March. The company stated that the leak emanates from 8,500 feet (3,000 meters) below ground and that two relief wells need to be drilled before the leak can be plugged. Brockovich, in a CNN interview, alleged part of the problem is that the well is old, dating back to the 1950s — and that Southern California Gas Co. never replaced a safety valve that was removed in 1979.

The gas company was not moving fast enough for Gov. Brown, who has already been accused by Porter Ranch residents of not taking action sooner. Yesterday’s emergency orders require all state agencies to contribute any needed personnel, equipment and facilities to the effort to stop the well’s leak. Regulators will monitor Southern California Gas Co. to maximize its efforts to capture leaking gas and store it elsewhere.

And in a move that suggests the gas company has not been transparent about the impacts of the Porter Ranch gas leak, Southern California Gas Co. will have to report on all of the company’s actions and reports related to the leak. The California Air Resources Board (CARB) will also have to develop a plan to mitigate the leak’s impact, which could have increased the state’s total methane emissions by 25 percent. Southern California Gas Co. will also be required to pay for the costs generated by the response to the leak, while ensuring ratepayers will be protected from any increase.

Image credit: Earthworks

A 2016 Carbon Market Forecast

By The Climate Trust

The Climate Trust, a mission-driven nonprofit that specializes in mobilizing conservation finance for environmental benefit, announced its third annual prediction list of 10 carbon market trends to watch in 2016.

The trends, which range from climate change playing a larger role in federal decision-making to increased carbon market linkage and momentum in conservation finance, were identified by The Climate Trust based on interactions with their diverse group of working partners—government, utilities, project developers and large businesses.

"The Trust pays close attention to market signals throughout the year, identifying areas where we can have the greatest impact," said Sean Penrith, executive director for The Climate Trust. "Each year, we look forward to putting together our team's collective knowledge and sharing our industry insights."

Carbon pricing will play a key role for many jurisdictions worldwide as they plan to meet their emission reduction targets from the Paris negotiations. Roughly 25 percent of the world’s emissions now fall under some form of carbon pricing system. In the aftermath of the Paris negotiations, this percentage is only expected to grow, as countries will be examining low-cost, high-impact options to comply with the nationally-determined emission reduction goals that they have submitted to the UN. Several jurisdictions worldwide have expressed interest in cross-border emissions trading, to lessen the potential economic risks from acting unilaterally.

The Carbon Pricing Leadership Coalition (CPLC), launched on the first day of COP21 in Paris, brings together key governments along with nearly 90 global businesses and NGOs to strengthen and expand carbon pricing worldwide. We expect to hear many more announcements of national carbon pricing initiatives in the coming year, as well as announcements of interest in linkages to and among existing systems. In addition, countries are confronting — for the first time — how setting and keeping emission reduction goals can be made easier by coordinating all their domestic climate policies in service of these goals; therefore, we expect to see more academics, industry groups and government coalitions weighing in on these opportunities for “complementary” policy.

In Oregon, policies related to clean energy will take center stage in 2016. Importers of transportation fuels will be under obligation to comply with the state’s Clean Fuels Program in 2016. This program is designed to reduce the carbon intensity of transportation fuels 10 percent by 2025, by integrating more low-carbon fuels (like ethanol and biogas) into the fuel supply. In addition, the 2016 ballot is very likely to contain initiatives that would increase Oregon’s acceleration of a clean energy transition, including phasing out the use of coal-fired electricity and increasing the state’s renewable portfolio standard.

Finally, carbon pricing will remain a topic of discussion during the 2016 legislative short session, as bills advance which could add enforceability to our state’s emission reduction targets by capping emissions from various economic sectors. We predict passage of at least one clean energy-related ballot measure this year. Carbon pricing in Oregon is still at least a year away, as even if a legislative bill were to pass in 2016, the state would need time to design and implement its optimal strategy.

Climate Risk Gets Real for Private Industry. Beginning with the groundswell at Climate Week in New York in September 2015, and becoming more strident at the Paris climate summit, it is clear that the era of managing and disclosing a corporation’s exposure to climate risk has arrived.

Nothing could have sent a clearer signal to the business community — Mark Carney, the governor of the Bank of England, announced the establishment of a new “Task Force on Climate-related Financial Disclosures” at the COP 21 in Paris. The chief aim will be to evaluate how well the financial markets disclose their exposure to climate risk. Carney commented that this effort was in response to the current “market failure” of providing appropriate information to investors, insurers, and lenders. Corporate leaders are realizing with stark clarity that a changing climate will have profound effects on business. Companies will continue to act with increasing velocity in 2016 to not only manage for risk but to monitor for opportunity.

Addressing climate change will play a larger role in federal decision-making and political platforms in 2016. With the energy created by the COP21 gathering in Paris still buzzing around us, a presidential campaign well underway, and a little more than a year left for members of the Obama Administration to leave their full mark on history, it seems clear that 2016 will be a year of climate action. Obama’s Clean Power Plan and his recent rejection of the Keystone XL pipeline, paint a clear picture of how the 44th president wants to be remembered with respect to climate change.

In June, the USDA announced it will take additional steps to integrate climate change adaptation into its programs and operations. Secretary of Agriculture Tom Vilsack has a little over a year left to make good on this promise. The Democratic candidates for president have also clearly indicated that climate change is an important part of their respective campaigns.

On a state level, California is working to extend the Global Warming Solutions Act beyond the current 2020 deadline with major decisions expected in 2016. Legislators in Oregon are hoping to implement a similar cap-and-trade program. In the Northeast, states participating in the Regional Greenhouse Gas Initiative (RGGI) are also seeing success. A Duke University led study suggests that emissions would have been 24 percent higher without RGGI, and an article published by the Energy Collective claims that early adoption of RGGI puts northeastern states ahead of the curve with respect to Obama’s Clean Power Plan.

Increased U.S. carbon market linkage as states prepare for the Clean Power Plan. The final draft of the Environmental Protection Agency’s (EPA) Clean Power Plan was released in 2015, with 24 states filing a lawsuit against the plan questioning EPA’s authority. The lawsuit is unlikely to succeed. In fact, many of the states involved in the lawsuit are still drafting compliance plans; 24 other states launched a countersuit in support of the plan; and George Bush’s EPA chief reminds the states that EPA’s authority has been upheld by the Supreme Court twice before.

The plan allows states to choose a mass or rate based approach to compliance. Many states will likely elect a mass based approach, because it allows for interstate trading, making compliance efforts more efficient. Gov. Andrew Cuomo of New York announced last October that the state would explore the possibility of linking RGGI — a cap-and-trade program comprised of nine Northeastern states — and the California/Quebec program, as these programs will likely be leveraged to comply with the Clean Power Plan. New Jersey is seeking to re-enter RGGI after Gov. Chris Christie elected to remove the state from the initiative.

We anticipate that in 2016, the opposition to the plan will fail, states will seek a mass based approach to compliance, and the use of carbon markets across the U.S. will grow as a result.

Conservation finance spurred by divest/invest movement. There has been a marked amount of movement in the finance arena. 2016 will see this turn to a flood coming out of the climate summit talks in Paris. The International Energy Agency has estimated that we need investment flows of $53T by 2035 to mitigate the projected catastrophe of runaway climate change.

The divest/invest effort has brought urgency to the need, and we saw many major institutions, such as the World Council of Churches, California’s Public Employees Retirement System, and the Leonardo DiCaprio Foundation all rise to the commitment to divest from fossil fuel as part of the transition to a clean energy future. DiCaprio’s divestment from his fossil fuel holdings has led to increased investment in renewable energy companies. To date, 430 institutions across 43 countries and representing $2.6T in assets have committed to divest from fossil fuel companies. Ahead of the Paris climate talks, we witnessed a fifty-fold increase in the combined assets of those entities pledging to divest from fossil fuels.

The Climate Trust predicts that this momentum will gain significantly in 2016. The divestment movement is providing a vital market signal to support the needed flows of conservation finance. These divestment dollars will continue to seek out a home investing in a low carbon economy that includes renewable energy, energy efficiency, smart agriculture, clean transportation, and forestry.

New legislation in 2016 will extend California’s cap-and-trade system to 2030 or beyond. California’s greenhouse gas (GHG) emission reduction targets currently end in 2020. Existing legislation gives the California Air Resources Board (ARB) the authority to continue to enforce the 2020 emissions target (a return to 1990 emissions), even after 2020. However, without new legislation ARB cannot require deeper cuts beyond this 2020 target. California is working now to create new, more stringent emission reductions targets for 2030 and 2050.

In April 2015, California Gov. Jerry Brown issued Executive Order B-30-15, which solidified this commitment by calling for a 40 percent reduction in GHG emissions compared with 1990 levels by 2030. With the cap-and-trade system as the backbone of California’s strategy for reducing GHG emissions, the continuation of their successful system will be essential to meeting these goals. As mandated by this Executive Order, ARB is currently developing a scoping plan to meet these 2030 emission reduction goals. New legislation is needed to give ARB the statutory authority to solidify the 2030 and 2050 emission reduction requirements in an extended cap-and-trade system.

Senate Bill 32, authored by Sen. Fran Pavley, proposed to give ARB this authority; it codified 2030, 2040 and 2050 emission reduction targets. On Sept. 13, 2015, the bill failed to pass the Senate floor after being read for a third time, and Senator Pavley announced she would present the bill again in 2016. We predict that 2016 is the year in which these new targets will be captured in legislation, and any uncertainty about the future of California’s cap and trade system will be significantly reduced.

“There really is a transformation afoot. Not only is there momentum around the issue of divestment out of fossil based energy and a surge in renewable investment, but there is also a growing recognition that finance must incorporate climate risk considerations," said Stacy Swann of Climate Finance Advisors, LLC. "This means that all investments–from buildings to roads to hospitals and schools–need to build-in resilience. This is a huge opportunity for orienting the entire financial system to become more sustainable and climate-friendly in both the short and long-term.”Continued tight spread between CCAs and CCOs. The California carbon market took a surprising turn in 2015. California Carbon Offsets, which have historically been valued at a 25 to 30 percent discount to California Carbon Allowances, shot up in the latter half of the year to a discounted value of 10 to 15 percent. A big reason behind the reduced spread was the November 2, 2015 deadline for compliance companies to surrender offsets and allowances to demonstrate compliance with the first compliance period reduction target.

The big question going into 2016 is whether this tight spread will continue or dissipate, as the second compliance period surrender deadline isn’t until late 2018. Despite the availability of allowances, offsets will show some staying power in 2016, as compliance buyers continue to search for lower cost compliance options. With offset supply forecasted to remain below the 8% limit, offsets that are issued and tradable in 2016 should expect to obtain prices that have a discount in the mid-teens range relative to allowances.

“One of the main factors contributing to this tight spread is the longer than expected lead time to verify and receive issued offsets through the Air Resources Board process,” said Chandan Kumar of Californiacarbon.info. "Therefore, this trend is expected to continue until the volume of projects increases, while the lead time for verification and issuance falls."California will lead the way in using shorter-term Global Warming Potential values. As the effects of climate change are increasingly felt and action is demanded, there is an increased focus on “short lived climate pollutants” like methane. To compare methane to the heat-trapping ability of carbon dioxide, it is assigned a global warming potential (GWP), or equivalency value for the amount of warming compared to carbon dioxide. Because methane has a short lifetime in the atmosphere and carbon dioxide has a very long one, the IPCC publishes different GWPs for different time periods.

Recent data shows that over a 100-year period, methane causes 28 times as much warming as carbon dioxide. Compared over 20 years, however, methane is 84 times as potent. It is up to regulators and policy makers to decide which time period is the most appropriate to use for comparison. This is a subjective judgement, trading off how to weigh the impact of warming in the short term versus warming in the future. The 100-year GWPs are by far the most commonly used—in CA’s cap-and-trade offset protocols, in the inventory for reporting the US’ GHG emissions, and throughout the Kyoto Protocol and other emerging international agreements. The IPCC writes, “there is no scientific argument for selecting 100 years compared with other choices," and California is intelligently beginning to question this paradigm.

The Climate Trust predicts that in 2016 policy makers and regulators become increasingly aware of this nuance, and begin to use GWPs with shorter time periods. A shift to 20 year GWPs could have a massive impact on The Trust’s ability to invest in projects. Offset protocols currently use the outdated 1995 100-year global warming potential for methane: 21. Updating protocols to use the current 20-year GWP, 84, would immediately quadruple the number of offset credits livestock digesters generate every year. Even with these outdated GWPs on the conservative 100-year time frame, carbon credits for the avoided methane emissions of digesters currently make up 20% of the revenue of projects. By quadrupling this revenue, many more of the potential digesters in this country could be quickly built.

The volume of forestry carbon offsets will continue to significantly increase in the California cap-and-trade program. Forest project offsets were the most rapidly growing project type in the CA compliance market in 2015. As of December 2015, Ozone Depleting Substances, Livestock, and Mine Methane Capture consist of 12,957,201 (or 38 percent) of the California Air Resources Board (ARB) offset credits issued. U.S. Forests constitute 20,933,016 (or 62 percent) of the issued offsets, approximately double that of all other project types combined.

The Climate Trust expects this trend to continue in 2016. There are still several Early Action Eligible Projects in the queue to be reviewed and potentially approved by ARB staff. These projects, which have been approved by voluntary registries for greenhouse gas reductions that occurred between January 2005 and December 2014, will add a significant number of offsets to the market in 2016. The cap-and-trade regulation requires that early action projects be reviewed and approved by ARB by August 2016. In addition, ARB adopted new Common Practice Values for all U.S. Assessment Areas on Nov. 2, 2015.

Over 65 new forestry projects were listed as potential ARB compliance projects before this date in order to make use of the older Common Practice Values, which in many instances are lower and thus more favorable for many projects. This includes over 35 projects with Climate Action Reserve, and more than 30 with American Carbon Registry. Not all of these projects will move forward, but it will be an option if the landowner decides the economic benefit is worthwhile. These newly listed projects will increase the offset volume from forestry projects in 2016 as well.

In late October ARB staff held a public workshop to present a white paper on the possibility of including international sector-based offsets in California’s cap-and-trade program. While ARB has not yet approved these offsets for use to meet compliance obligations under AB 32, ARB staff have presented a compelling argument for why REDD offsets should be allowed for the third compliance period starting in 2017. Despite the challenge of ensuring that these offsets meet the same standards as CCOs, The Trust expects that ARB staff will establish the framework by which REDD offsets can be approved for compliance in the state’s cap-and-trade program in 2016.

“In 2015, a number of our predictions came to fruition, including increased public sentiment and political will around the impacts of climate change, the extension of Oregon's Clean Fuels Program, and approval of a new compliance offset protocol for rice cultivation projects,” said Sheldon Zakreski, director of risk management for The Climate Trust.“ In late 2015, The Trust was awarded a $1M USDA grant to build an innovative conservation investment fund for biogas, forestry and grassland conservation projects; offering a tremendous opportunity to cost-effectively mitigate and sequester carbon emissions.

For a full accounting for how The Trust measured up to our 2015 predictions, take a look at our hindsight assessment from Executive Director, Sean Penrith.

Image credit: Flickr/Yann Caradec

5 Solar Energy Trends for 2016 in the Residential Market

The U.S. has enough installed solar energy capacity to power 4.6 million homes. Solar energy accounted for 32 percent of total new power generation in 2014, exceeding coal and wind energy but lagging behind natural gas. In just nine years, the installed cost of solar energy has fallen by more than 73 percent – setting up the industry for explosive growth.

TriplePundit spoke with Vikram Aggarwal, founder and CEO of EnergySage, the so-called "Expedia of solar," about solar energy trends and what to expect for 2016 in the residential market.

1. Unprecedented boom continues

Last year, analysts predicted that solar would grow by 57.4 gigawatts in 2015. The recent five-year extension of the investment tax credit (ITC) in the U.S. for both residential and commercial installations further enhances the growth trend. Now that solar manufacturing capacity has expanded significantly, the price of solar equipment has plummeted – making solar energy cheaper than grid-supplied power in many markets.

“The residential solar market is a vibrant $7 billion industry, and on track to generate more revenue by year-end 2016 than Major League Baseball,” Aggarwal said. “The economics of solar are rapidly changing for solar shoppers, installers and financiers alike."

2. Misinformation in the solar market continues

The solar industry continues to change and evolve so quickly that it is difficult for the average consumer to stay on top of all the needed information. In some cases, sales tactics have hurt consumers. "I think some of the larger solar companies have relied on very aggressive marketing, going door-to-door, calling, and have not had very transparent practices," Aggarwal told 3p. "It has created lots of skepticism."

Lack of understanding prevails, making transparency by the solar installers and unbiased third-party sources of information especially important for solar shoppers to make informed choices. Solar system owners can typically save a lot on utility bills, but lack of information plagues the industry.

"Solar has migrated from being a niche, environmentally-driven product to one where financial savings are driving the interest in solar," Aggarwal explained. "Many consumers have misconceptions that solar is very expensive and may not pay off. We are working to help consumers realize that solar can actually be very financially rewarding."

3. Dizzying array of solar options

Solar shoppers now have more equipment, ownership and financing options available to them than ever before, but this can be overwhelming. Forty financing companies, 43 solar panel brands and 24 inverter brands bid out on the EnergySage Solar Marketplace. It is especially misleading when solar installers push one package and are not transparent about all the options, as solar shoppers often get a lot of information from solar salespeople.

EnergySage, which has been described as the "Expedia of solar," allows consumers to comparison-shop for solar, with simple, clear information. Because it is not affiliated with a manufacturer, financing company or installer, shoppers have access to objective third-party information and can get quotes from pre-screened solar companies for a true apples-to-apples comparison. Such services are necessary for solar consumers to find the best solar solution for their situation, possibly saving thousands in the process.

4. Solar financing options expand

The EnergySage Solar Marketplace Intel Report states, "In [the first half of 2015], consumers paid on average $3.79 per watt in gross cost and achieved payback in just 7.5 years." Given that the design life of most solar equipment is 25 to 30 years, solar is now a sound investment in many areas, rivaling the returns of many traditional investments. Solar system owners can often save money from day one with a solar system.

Now that solar has proven itself as a safe, low-risk, high-return investment in many regions, it is much easier to obtain financing for solar technology. Low-interest loans with as little as no money down are available to solar shoppers, reducing the hurdles to solar ownership. It is also making solar ownership more appealing and advantageous than solar leases to many homeowners.

5. Solar is generating the majority of home electricity consumption

For homes with solar, the systems met an average 85 percent of total demand in 2015, and the average 7.9-kilowatt system saves roughly $2,000 on electricity costs each year, according to the EnergySage Solar Marketplace Intel Report. This is made possible by solar equipment efficiency gains, as more energy can be created from a smaller surface area. There are now solar panels on the market that are more than 22 percent efficient. In the laboratory, solar cells have been developed that are 40 percent efficient, but this technology isn't available on the market yet.

Image credit: 1) Pixabay 2) Sarah Lozanova

Why Not Eating Meat Should Be Your New Year’s Resolution

“For about 10,000 years people and cows have had a mutually beneficial relationship. We gave cows pastures and protected them from predators. They pulled our barges, plows and wagons. About 50 years ago in the United States that fell apart,” says Denis Hayes, president of the Bullitt Foundation and co-author of "Cowed: The Hidden Impact of 93 Million Cows on America’s Health, Economy, Politics, Culture, and Environment."

“We started to want really cheap food like burgers. To produce that, we moved cows into Confined Animal Feeding Operations (CAFO) and fed them terrible things … grains that they didn’t evolve to be able to handle. The consequences have all been negative for America’s public health, the environment and the economy.”

Hayes has spoken out on this topic at sustainability conferences such as Verge and with eco news sources like Grist. His goal is not to convince people to stop eating beef. Instead, he tries to convince readers to reduce their meat consumption.

Reducing the amount of burgers you eat is a great first step. If Americans reduced meat consumption, the benefits would be epic. But since all of us are already environmentally conscientious, let's go one step further and talk about the 10 reasons we should make not eating meat our New Year’s resolution.

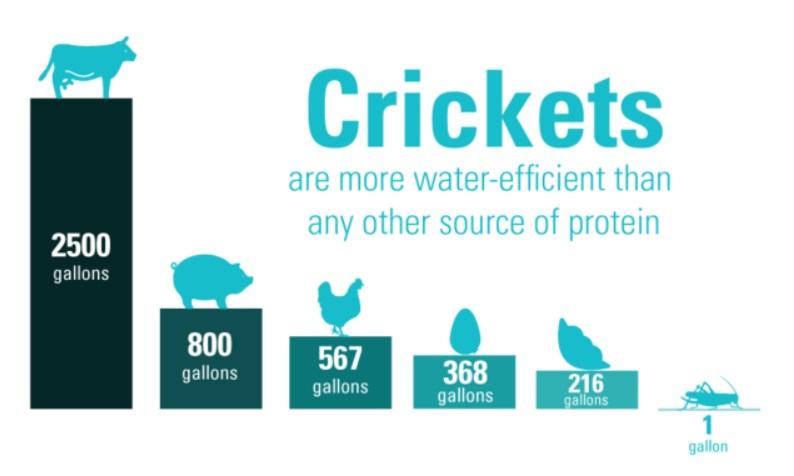

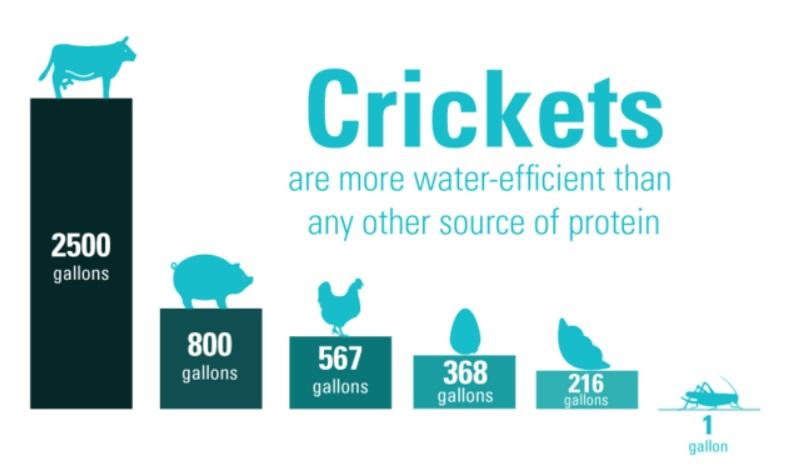

1. The water it takes to produce 10 burgers is the same amount of water you use to shower for a year. In fact, agriculture is responsible for 80 to 90 percent of water consumption in the U.S. “One pound of beef equals 2,500 gallons of water. But cows are not the only water hogs. Sorry, bacon lovers: One pound of pork requires 800 gallons of water. Apologies, benedict fans: A dozen eggs need 636 gallons of water,” says Leslie Ziegler, cofounder of Bitty Foods, a startup that sells tasty baked goods made with cricket flour.

Crickets, on the other hand, only need one gallon of water per pound. “Crickets are nutritionally complete, contain fiber, Omega-3 fatty acids, and a slew of other important vitamins and minerals. They take up just 2 square feet of pasture per pound versus beef’s 200 square feet. They emit zero greenhouse gases. Even the United Nations put out a report calling edible insects a ‘key to global food security.’”

Almost all of the facts below were compiled by the documentary "Cowspiracy," and the original sources are listed on its website.

2. Animal agriculture causes 18 percent of greenhouse gas emissions. That’s more than cars, trucks, trains, airplanes and all other vehicle transportation put together. We regularly talk about taking public transportation, car pooling, cycling and buying carbon offsets when we travel. All of that is important, but reducing our meat consumption would have an even larger environmental benefit.

3. Three-fourths of the world’s fisheries are exploited or depleted. Sure we know that troll- or pole-caught fish is more sustainable. But should we even be eating fish? Given the current rate of fishing, we could have fishless oceans by 2048. Some estimate that as many as 2.7 trillion animals are harvested from the ocean each year. It’s time to give the oceans a break and let them recover from their traumatic loses.

4. Animal agriculture is responsible for up to 91 percent of Amazon destruction. Estimates vary, but up to 137 plant, animal and insect species are lost each day because the rainforest is being torn down.

5. Get this, 1.5 acres can produce 37,000 pounds of plant-based food. In contrast, 1.5 acres can only produce 375 pounds of meat. Many people don't have enough food to eat today, and the world's population is quickly growing. One way to help ensure that there's enough food for everyone is to reduce our consumption of animal products because it's unsustainable. However, we can feed everyone if we eat plant-based food instead.

6. Every day you eat vegan meals, you save 1,100 gallons of water, 45 pounds of grain, 30 square feet of forested land, 20 pounds of CO2 equivalent emissions and one animal’s life. Wow. When I learned this, it made me realize that taking shorter showers, turning off lights and taking public transportation were only a small fraction of what I could do. By becoming mostly vegan, I had more power to do good than I had realized!

7. Animal agriculture is the No. 1 reason for species extinction, ocean dead zones, water pollution and habitat destruction. When we eat packaged food from the grocery store, we become very detached from the source of our food. We don't know how it's grown and processed or the larger impact it has on the environment. It's good to try to take a step back and look at our eating habits from a third party's perspective and look at the big picture to see how we're impacting the world.

8. Livestock operations have created more than 500 nitrogen-flooded deadzones around the world in our oceans. I had never heard of a nitrogen dead zone before, so I needed an explanation. Here's what's up. Dead zones occur when nitrogen and phosphorus from agricultural fertilizer and sewage enters the ocean. Ewww. It creates a zone of oxygen-depleted water. This kills the plants and fish in the area. For example, the northern part of the Gulf of Mexico has a 6,000-square-mile dead zone full of dead everything.

9. Not eating meat works wonders for your health. No surprise here. The Harvard School of Public Health discovered that “eating even small amounts of red meat, especially processed red meat, on a regular basis is linked to an increased risk of heart disease and stroke, and the risk of dying from cardiovascular disease or any other cause.” Additionally, a report by the World Health Organization released earlier this year found that processed meat likely leads to cancer.

10. Consistency. If we say we care about the environment, then to be consistent with our beliefs we should take big steps to reduce our environmental impact. For most, if not all of us, not eating meat is the easiest way to have a significant positive impact on the environment. Imagine what the world would be like if everyone mostly ate plant-based foods?

No meat, no ‘mo problems. Or something good like that. Bring on the fruits and veggies!

Image credit: Flickr by Steven Zolneczko

Chart credit: Leslie Ziegler

What Paul Graham Misses On Value Creation and Income Inequality

One of the reasons I love business as a means for change is the focus on value creation. At its most simple, a successful, money-making business takes low-value goods and services, works magic on them, and sells them at a higher price. 7-11 sells old milk at a higher price than Safeway because it provides the value of a quick, convenient transaction to its customers. TriplePundit convenes a group of smart, highly-educated sustainability professionals, and our advertisers hope to catch your attention while you're here. I love the simplicity and efficiency of value creation. The other amazing thing is that there isn't a finite pool of value -- the whole Silicon Valley venture capital movement (and the influx of rapidly increasing numbers of 'unicorns') shows us that investors believe the sky is the limit on how much value can be created.

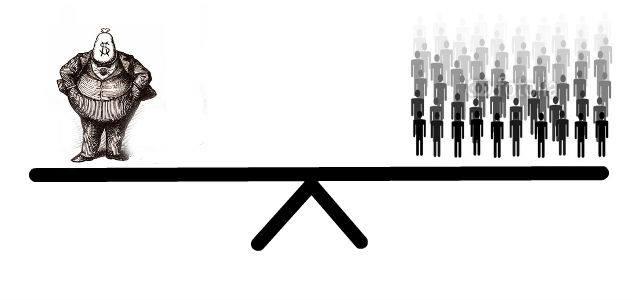

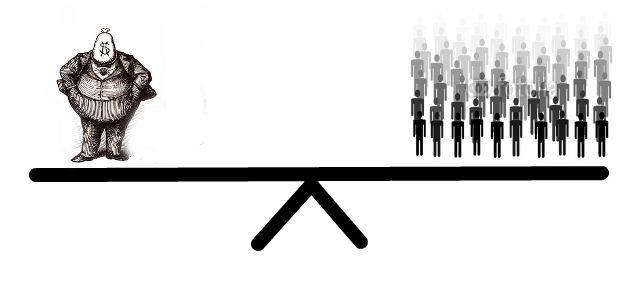

Last week, Paul Graham, the rich-and-famous founder of the Y Combinator accelerator, argued that income inequality isn't necessarily bad because when people get rich from value creation (as opposed to rent-seeking or taking advantage of poor people), they aren't taking anything away from anyone else. That's true to a degree -- the fact that WhatsApp was valued at $19 billion doesn't mean the mouths of babes were immediately robbed. A few founders got massively rich because they happened to have access to a customer base that was deemed very valuable to Facebook. They didn't get rich ripping coal out of mountains at the expense of coal miners' lungs and kids' asthma rates. Graham would argue that their massive wealth doesn't hurt anyone. But I see differently.

No, massively wealthy entrepreneurs don't directly hurt poor people. But their spending power does. Silicon Valley's concentration of extreme wealth and limited land means that individuals and businesses can very quickly drive property values sky-high.

Mountain View, California, whose commercial real estate landscape I covered in the fall as a part of our Tech Titans series, has sky-high residential property rates as well. The median home value right now in Mountain View is $1.4 million. Now, Mountain View is a perfectly nice place to live, but it's not a Shangri La. The schools are pretty good; its walk scores are mediocre. The only thing the location really offers is easy access to companies that pay extremely well -- which means many prospective home buyers have the income to be able to afford to bid up the prices of real estate. That's all fine and good -- supply is limited and demand is high, so the price goes up. That's exactly how the economy is supposed to work.

But the trouble with skyrocketing real estate rates is that the costs of doing business -- normal non-IT business like running a dry cleaner, yoga studio, bike shop or grocery store -- goes up too, which increases the cost of living across the board. Don't believe me? The average cost of gas in Mountain View is $2.83 per gallon, 39 percent higher than the national average. National daycare rates vary widely, from $3,582 a year up to $18,773 with an average of $11,666. Recent estimates from the Bay Area make the high end of that range sound sweetly affordable -- average rates are more like $1,500 to $2,500 per month or an average of $24,000 per year. Yes, that buys great coverage for people who can afford it. But that isn't the end of the story.

When costs go up faster than wages, real families get pinched from every angle. Especially if they don't happen to work for one of the gold-star companies that pays out the big bucks or they happen to have a single wage earner. For those folks -- and I'm not talking about mechanics and waitresses, I'm talking about lawyers, engineers, nonprofit directors, project managers and small business owners -- the cost of living becomes impossible, and the choice becomes clear: Start coding and work for a tech titan, live like a pauper, or move out of the area. It's actually farcical when you do the math. A family can be in the top 5 percent for national incomes, earning over $166,000 per year, and find home ownership laughably out of reach.

The downpayment on one of those median Mountain View homes would be $280,000 with a mortgage over $5,000 per month. Add in $2,000 a month for a single child's daycare, and you are dangerously close to the $8,000 per month in net pay you'd take home on that $166,000 annual salary. There's only $1,000 left for savings, food, clothes, transportation and healthcare costs, for the whole family. It's simply untenable.

So, it comes back to: What's the point of it all? Well for me and pretty much everyone I know, work is about a lot more than a paycheck. We have the privilege of having meaningful work -- doing something we happen to be good at and making a difference at the same time. Many of us are trying in one way or another to make the world better than we found it -- and I don't mean world-changing in the software sense. If we have to give that up in order to live, life loses some of its purpose. And these middle-income families, so privileged in raw numbers yet poor in terms of local earning power, leave Paul Graham's Silicon Valley, increasing local income inequality.

"Innovators" in the startup sense provide financial value for their owners and investors, there's no doubt. But the floods of funding to a narrowly-defined "value" absolutely increases income inequality by raising prices across the board. Show me how I'm wrong, Paul.

The Conflict-Free Effect: Better for Society, Better for Business

By Carolyn Duran, Intel

At the Consumer Electronics Show, our CEO announced that Intel is moving beyond microprocessors to achieve the goal to validate our broader product base as conflict-free in 2016. This news is the culmination of seven years of dedicated work to remove conflict minerals – gold, tin, tantalum and tungsten – from Intel’s supply chain and prevent profits from the sale of these minerals from funding armed conflict in the Democratic Republic of the Congo (DRC). It’s a milestone that we’re very proud of both as a company and as individuals.

We also know that the job is not complete. We will continue to monitor our supply chain and address challenges as they arise, whether they come from the supplier, the smelter or from the mines themselves. We will stay diligent and continue to improve the processes and systems in place to responsibly source from the DRC.

As excited as we are about this accomplishment, we also realize that the commitment of just one company isn’t enough to make conflict-free the industry standard. And while we feel that sourcing conflict-free minerals is simply the right thing to do, we realize that it’s also an investment of both time and money. With that in mind, we want to inspire other companies to join our mission by laying out the business case for going conflict-free.

To help illustrate the myriad of business benefits, Intel recently commissioned an online survey of 500 U.S. millennials, in partnership with Penn Schoen Berland, to assess millennials’ attitudes about conflict-free products. The survey found that millennials, who collectively possess billions of dollars in spending power, highly value social responsibility. Ninety-seven percent of those surveyed believe it’s important for companies to act in a way that benefits society, but only 23 percent believe that large companies are having a positive impact on society today.

When it comes time to purchase new products, 69 percent of millennials surveyed stated that they avoid buying products from companies that negatively impact society. That number is enormous, and not one that can be ignored as businesses develop new products and services for consumption by this generation.

What’s even more interesting is that only 35 percent of millennials surveyed have heard of conflict minerals. Our survey shows that most millennials care about conflict minerals once they’ve been educated about the issue, opening up a huge opportunity for businesses to be the impetus of that education for the other 65 percent, which will help bring awareness to a serious global issue and build brand appreciation and loyalty.

This generation is looking to us to do the right thing. In fact, after being educated about the issue of conflict minerals, more than half of millennials surveyed said they believe technology companies are responsible for taking action on the issue of conflict minerals – more than mineral suppliers, governments, consumers or NGOs. The question isn’t will millennials care about this topic, but when.

While my team has been traveling around the world validating -- smelter by smelter -- that our supply chain is free of conflict minerals, college students on campuses around the country and activists in Washington, DC have been working hard to build awareness about this important issue.

It’s clear from the survey findings that we must align our consciences with our business models to bring the greatest benefits possible both to society and to our organizations. So how can we make this happen?

There’s no doubt that it appears to be a daunting undertaking. At first, Intel’s mission to remove conflict minerals from its supply chain seemed like a near-impossible challenge – but instead of avoiding the issue by sourcing minerals from other regions of the world, Intel made a commitment to continue sourcing from the DRC. We worked hard to find creative solutions and to help implement the systems required to achieve a conflict-free supply chain. And Intel is not alone. Many technology leaders have come together. Today, we have an effective supply chain audit process, which paved the way for the global Conflict-Free Sourcing Initiative.

While Intel has achieved its goals to validate more and more products as conflict-free, our journey is far from complete as we seek to encourage our partners, peers and competitors to undertake this very worthy goal. We must join together and continue educating consumers about conflict minerals to make faster and deeper strides toward conflict-free products worldwide.

This resource is a fantastic place to start, especially since much of the trail has already been blazed.

Image courtesy of Intel

Carolyn Duran is Supply Chain Director and Conflict Minerals Program Manager for Intel.

Bouqs Wants You to Send Flowers from Farm to Table

We have all survived another Christmas and New Year’s season, just in time to be tantalized by displays touting Valentine’s Day. That means some of us need to remember to send that special someone flowers to show our love, devotion and tax bracket. Or maybe we just want to celebrate being single and send flowers to ourselves.

That often means having those flowers delivered, which even during this age of online ordering can be a headache. While online shopping has become so easy it’s almost the new addiction, finding that special bouquet is annoying. There are constant upsells, tacky frills that we wish weren’t on the bouquet and then, in the age of free shipping, comes the exorbitant delivery fee (isn’t oil at under $40 a barrel now?).

Then, of even more concern to 3p’s readership, is the flower industry’s impact on people and the environment. The demand for freshly-cut flowers, and the often nefarious results, have long been documented in the media. The opening scenes of "Maria Full of Grace" are the reality of many workers in Ecuador, Colombia and Mexico: Low pay, sexual harassment and human rights violations such as child labor have been documented by several NGOs. Fair trade flowers are available, but in the rush to deliver those $1.5 billion to $2 billion worth of flowers on Feb. 14, that option is often overlooked. Despite the imagery, the flower industry is ripe for innovation and humanization.

One Southern California company is changing how flowers are sourced and sold. Bouqs, based in Venice, California, promises to deliver flowers directly from farms in South America. Customers can visit the company’s site and select a bouquet, and they will receive their selection anywhere from two to four days later, as opposed to the 10- to 14-day average flowers take from when they are cut to time of delivery. Less storage time also means less waste — anywhere from 33 to 40 percent of all flowers marketed in the U.S. end up never sold. And on the business side, pricing is simple -- as low as $40 flat for all of its featured bouquets, including delivery. Although the flowers sourced from its farm in Ecuador are not officially certified, the company claims its partner offers day care, health care and education for its employees — while practicing “sustainable, eco-friendly farming.” As far as flowers go, this is about as farm-to-table as you can get.

The result is a company that has scored press across the board, from the Wall Street Journal touting the impression Bouqs has made on investors, to celebs showing off the startup’s arrangements. Meanwhile the company is recruiting florists to join its network. With a solid business model and the drive to make this industry more humane and sustainable, this young company is poised for even more growth and disruption. For once, that Valentine’s Day bouquet may actually be a guilt-free purchase.

Image credit: Bouqs

Wendy’s and Subway Are Saying Hello To Cage-Free Eggs

More hens in North America will have more space to be chickens and practice normal chicken behavior. Two more companies recently announced they will transition their egg supply chains to cage-free systems and away from cruel confinement systems.

Wendy’s is one of those companies. The third largest quick-service hamburger company will transition to 100 percent cage-free eggs in its U.S. and Canadian locations by 2020. It’s a commitment that will affect over 400 Wendy’s restaurants in the U.S. and Canada that serve breakfast.

Wendy’s started its animal welfare program 15 years ago when it began working with animal welfare experts to audit its suppliers' animal handling practices. It established its Animal Welfare Council in 2001 and an animal welfare program that covered all of its meat suppliers. The company has also committed to phasing out the use of sow gestation stalls from its pork supply chain by 2022 as part of its animal welfare program.

“We feel moving to cage-free eggs is the right direction for Wendy’s, but it’s important to note that we are mindful of the amount of energy it takes to make this type of change within the supply chain and specifically the responsibility it puts on our valued suppliers,” Wendy’s spokesperson Bry Roth told TriplePundit. “We’re committed to working with them on a phased implementation that ensures we’re delivering a quality product for our customers.”Subway is the other company to announce its commitment to transition to cage-free systems for egg-laying hens by 2025 for its 30,000 locations across North America. The company’s egg supply chain in Europe and Australia is already cage-free. As Elizabeth Stewart, director of corporate social responsibility for the company, said in a statement: “Subway customers across Europe are served only eggs from free-range hens and in Australia are served eggs from cage-free hens.”“Wendy’s further demonstrates that confining egg-laying chickens in cages is out of step with the major players in the food industry and American consumers,” Josh Balk, senior director of food policy for the Humane Society of the U.S. (HSUS), told Triple Pundit.

The U.S. is shifting away from caged systems

Most egg-laying hens in the U.S. are forced to live their lives in battery cages where they are only given 67 square inches of space. That is less than one sheet of letter-sized paper, according to HSUS. Such little amount of space leaves hens no room to spread their wings or practice normal chicken behavior like nesting, perching and dustbathing. Those are behaviors experts say are necessary for the welfare of hens.Many egg producers are switching to cage-free systems, in part because of public opposition. Stewart pointed out in her statement that Subway is aware that consumers want to know that the “food they eat is ethically sourced." She added that Subway’s “customers care deeply about animal welfare.”

Another reason is California’s Proposition 2, which voters passed in 2008, that requires all egg producers in the Golden State to switch to cage-free systems. The law went into effect on Jan. 1, 2015. Since then, a number of companies have announced they will phase out battery cages from their egg supply chains, including fast food chain McDonald’s. Other companies have announced they will expand cage-free eggs such as major egg producer Hickman Family Farms.

Clearly, the U.S. is shifting away from cruel confinement systems such as battery cages. Consumers just aren’t comfortable with eating food produced in inhumane methods any longer. Back in May, 62 percent of Americans said that animals deserve some protection, according to a Gallup poll. Only 3 percent said animals deserve no protection.

Chances are great that this year will see more companies making announcements that they are phasing out battery cages.

Photo: Grey World

Is 2016 the Year of Community?

By Marianne Hughes

Could 2016 be the year when big businesses become a bigger part of local communities? It seems as we enter the new year, the brands we all recognize are prioritizing local action. But how can local action become scalable for large corporations?

We left 2015 fresh from COP21, where discussions flourished on the role of business in climate change, and so inevitably in local communities. Most recently over the festive period, we have heard about the impacts of flooding closer to home. Business in the Community wrote about the response of businesses to the flooding, showing wide contributions from brands we know such as Waitrose and the Post Office. As we enter 2016, Marks and Spencer is making bold statements, as Mike Barry, its director of sustainable business, announced that community will be put at the heart of the company's business in an article for The Guardian.

At GivingForce, our clients, such as RBS, also show bold efforts to integrate with local communities, for example with ATMs now allowing users to donate to local charities. As these local movements continue to grab our attention, we wonder if this is the sign of a clear trend that will continue into 2016?

Why is a local community focus important to corporations, and why in 2016? An obvious observation is people feel more connected to social and environmental issues that are close to home. So, we must be able to recognize businesses acting on a local level in the communities where we live. One way businesses can go about creating local impact is through their employees. Getting employees involved with the local community, whether it's through volunteering or payroll giving, fosters a connection between corporations, communities, charities and employees. In 2016 it seems the discussions about global issues must take place on a local level more than ever. BBC news reported that since COP21 we want to know what the implications of climate change will mean for us as individuals, and further for our communities.

How can big businesses make this the year of community? Are there any tools which could help to make local actions scalable? A challenge for big business to achieving local activity is how to act locally whilst being centralized nationally or internationally. For example, when employees are volunteering with regional charity partners, how can central administrators track and report on their group activities?

Our research shows that technology can help to make local actions trackable and scalable. There are a range of tools and methods which TriplePundit readers might recognize. Moving to the technology sector itself, 3p reported in 2015 that big tech corporations were under our philanthropic watch. Mark Zuckerberg’s decision to donate the majority of his Facebook shares to philanthropic causes has to be one of the most talked-about topics for the latter half of the previous year. Facebook as a corporation is trying to localize its activities, too, causing controversy in India over the Facebook basics options for rural Indian communities.

Society’s expectations and opinions on big business in local communities seem to cause much to be debated. Whilst using technology is important, a point which Mike Barry importantly makes in his article for the Guardian is that the key to local connections is through offline activities and personal connections. Technology is an enabler for local relationships. So, what are we waiting for? Let’s get offline from reading this blog post and get involved with business in the community this year!

We would be interested to hear the the views of the 3p community.

Image credit: Flickr/JamesMarianne works within client relations at GivingForce. GivingForce is the corporate employee engagement portal relied upon by FTSE100 organisations. The GivingForce portal covers volunteering, matching, payroll giving and corporate donations from one employee self-service location. Administrators can log in to access real time or scheduled reports. For more information please visit our website.