Urban Development Spurs Growth in Emerging Economy Cities

Reducing pollution and waste in cities around the world has become an ever more important priority in recent decades, particularly in developing and less developed countries. With more than half the world's population now living in cities and urban areas, the Urban-LEDS project is helping local governments in emerging economy countries devise and implement plans that lower urban greenhouse gas emissions, conserve resources and improve quality of life.

In a recent progress report, Urban-LEDS announced that all eight model cities, as well as several satellite cities, participating in the project have conducted or are finalizing greenhouse gas emissions inventories. That paves the way for these cities to craft practical, effective emissions-reduction projects.

In the northeast Brazilian city of Recife, the Torre Charles Darwin, a 35-story skyscraper, will be the first building in the city to have a green roof. In addition to a cover crop of 2.8 million square feet, Torre Charles Darwin will have a rainwater harvesting system that will be used to power the tower's air conditioning system.

Low-carbon development in emerging economy cities

Funded by the European Commission (EC) and managed by U.N.-Habitat and ICLEI Local Governments for Sustainability, Urban-LEDS's overarching goal is to promote and foster “the transition to low emission urban development in emerging economy countries.” Collectively, 37 cities, towns and metropolises are participating in the program -- representing over 700 million people, or around 10 percent of the world population.

Launched in 2012 with a budget of 6.7 million euros (~$7.7 million), Global-LEDS will be operational for 42 months. Depending on the program's success, the benefits realized by city-dwellers in emerging economy countries could persist for decades.

Urban-LEDS projects in the eight model and additional satellite cities hinge on being able to accurately assess urban resource needs, use and emissions. Completing emissions inventories per city-based GHG accounting standards – as all eight model and several satellite Urban-LEDS cities have done – is a key step forward.

Green roofs and LED street lighting

Urban-LEDS highlights the progress being made in its latest newsletter. Besides the first green roof in Recife, the Brazilian “model city” Fortaleza “now has a better understanding of where and how emissions can be decreased due to development of its first GHG inventory.”

The Fortaleza government recently launched an energy-efficient building pilot project in which 13 schools are participating. Highlighting how low-carbon development can stimulate sustainable local economic growth and job creation, the city government “is hiring construction companies and Acqua certifiers for the first pilot plant.”

In South Asia, the Indian Urban-LEDS model city of Thane has contracted an energy service company to audit 10,000 of 70,000 street lights.

Part of its broad-based emissions mitigation actions, a financial plan for installation of more efficient light-emitting diode (LED) street lighting is being formulated. That's expected to improve illumination levels and contribute to raising the energy efficiency of public power infrastructure, as well as reduce and enhance operations and maintenance.

In Rajkot, another Indian Urban-LEDS model city, planners are working up green building guidelines and training programs for sustainable transportation and industrial energy efficiency. These include a feasibility study for implementation of LED street lighting to be conducted by an energy service company.

These are just a few examples of the the low-carbon urban development plans and actions being taken in Urban-LEDS cities around the world. For more, check out Urban-LEDS latest newsletter and website.

Editor's note: An earlier version of this post reported that more than 1,000 cities were engaged with Urban-LEDS. This figure refers to ICLEI's membership, and 37 cities are now engaged specifically with this Urban-LEDS program.

*Image credits: Urban-LEDS

Chicken of the Sea Cuts Water Use, Waste

Seafood giant Chicken of the Sea’s latest corporate sustainability report reveals some important milestones the company achieved in 2013. Among the most notable was a 27.8 percent reduction in waste. The company also cut water use by 12.8 percent for every case it packed.

The report documents its efforts, with a focus on “four pillars” of sustainability, and sets goals to be met by 2020.

The four pillars are: employees, facilities, products and suppliers. And goals were set in the following areas: energy, waste, water, health and safety, and supply chain. This is the third year Chicken of the Sea has collected comprehensive data on practices throughout the company and its supply chain.

“Past reports and research have been critical to our understanding of the current and potential global and industry sustainability landscape, and where we stack up in that environment,” said David Roszmann, the seafood giant's chief operating officer and leader of its sustainability initiatives. “This year, we were able to take our work to the next level by adding specific, measurable goals in areas that matter most. Our vision is to be the first consumer choice in seafood, and to get there, a clear sustainability path focused on continuous improvement is critical.”

The company summarized its sustainability goals and the progress it made in 2013:

- 20 percent reduction in electricity and natural gas use (per standard case of product) by 2020: As a result of retrofitting its canning facility for lighting upgrades in high-traffic areas, Chicken of the Sea reduced electricity usage 4.4 percent in 2013, when adjusted for production. The company plans to use a variety of measures to continue to reduce its usage, such as reducing lighting and HVAC in unused areas and during non-production times, installing LED lighting, and working with a consultant to identify additional cost-efficient, energy saving measures for its facilities. Natural gas use increased by 10.2 percent on a production-adjusted basis and is a focus for future efficiency improvements.

- 30 percent reduction in landfill waste (per standard case) by 2020: In 2013, the company recorded a 27.8 percent drop in the amount of waste it takes to produce a case of product. It attributed this to implementing a new recycling program in its production areas and training employees on recycling and waste minimization practices. The company says it will put additional waste reduction initiatives into place this year.

- 15 percent reduction in water use (per standard case) by 2020: The company’s 12.8 percent water reduction was a result of conservation efforts, the reports authors said. These included installing new thaw chambers at its Lyons, Georgia, canning facility in 2012 and limiting in-process water usage, such as monitoring wash-down hoses to prevent wastewater when not in use.

- Maintain or reduce safety incidents by 2020: In 2013, the company saw a 40 percent lower incident rate than the previous year, experienced only six lost workdays and averaged a 2.5 incident rate -- compared to the state of Georgia’s 5.4 average incident rate.

- Audit 90 percent of seafood procurement spend (on a three-year rolling basis) by 2020: The company audited 37 percent of its vendors and suppliers in 2013 as it launched a formal sustainability auditing process. “The third-party audits look at its suppliers’ labor and human rights performance, environmental management systems, and overall business practices.” The company says it will audit additional suppliers each year and re-issue audits every three years.

“Looking ahead, we face very real challenges,” said Shue Wing Chan, Chicken of the Sea's president and CEO. “On the environmental front, we must find better ways to improve our natural gas use, which increased by 10.2 percent on a production-adjusted basis. While we have begun to investigate our options, we must be aggressive at identifying and implementing new technology and behaviors.”

Chan added that the company “must continue to pay close attention to our supply chain impacts … Over the next few years, we will be placing particular attention to working with our parent company and our key suppliers to ensure that labor and human rights are upheld from ocean to table.”

Chan is correct when he says supply chain, human rights and labor issues are an “industry-wide challenge.” And auditing 90 percent of seafood procurement spending is even more ambitious.

Image credit: Chicken of the Sea's 2013 corporate sustainability report cover

Forum for the Future launches trends tracking digital platform

Forum for the Future is opening up access to its futures knowledge and expertise through a new digital platform, www.thefuturescentre.org.

The sustainability non-profit believes the site will prove a powerful tool for decision makers to track trends, share resources and spot opportunities for sustainable innovation and collaboration. It also hopes that it will increase its impact in sustainability on the global stage.

The platform works by allowing users to tap into a vast online bank of futures knowledge and monitor change in dynamic fields, such as land-use, manufacturing, ecosystem health and social demographics, so that they can better understand the challenges in today’s changing world and more easily identify windows of opportunity to accelerate positive change.

Sally Uren, ceo, Forum for the Future, said: “Futures techniques enable leaders to look beyond the here and now and see how their organisations might fare in a radically different world. For nearly two decades we have been working with our partners to help them understand just how different that world could be, giving them the insights and confidence they need to help prepare for different scenarios.”

Over the next year, the Futures Centre will bring together some of the world’s leading experts to explore a number of critical issues in more detail through “topic hubs”. The first of these is due to go live in April and will be looking at the future of shipping.

Picture credit: Picture credit: © Rolffimages | Dreamstime.com - Future Man Photo

Chipotle’s Earnings Call: A Business Case for Sustainable Sourcing

Usually earnings calls are rather dry and pallid unless you are a stockholder excited about a company’s remarkable financial performance — or livid over a steep drop in stock price.

The investor relations officer will start by reading a safe harbor statement, reminding listeners that the company’s liability is limited should future results prove different from what is stated in the one-hour or so discussion. The chief financial officer may talk about additional details such as non-GAAP financial measures and details over adjustments to reconcile net income to net cash.

But Tuesday’s earnings call by Chipotle Mexican Grill, Inc. was much more than a laundry list of financial accomplishments: It stood out as a remarkable business case for the sourcing of sustainable meat and sticking to a business's principles.

If you were smarter than me and bought Chipotle stock five or so years ago, you are laughing. The stock yesterday was listed at $676 a share -- off a bit from its 52-week high of $727, but it has still been performing at an upward trajectory for almost 10 years. The company is successful: Fourth-quarter earnings were up 26.7 percent to $1.07, and 60 new restaurants helped boost sales that were already up 16.1 percent in comparable stores. Diluted earnings per share were at $3.34, up well over 50 percent. And 2014 was overall a banner year, with revenues up 27.8 percent to $4.11 billion, impressive considering many fast-food restaurants such as McDonald's are languishing.

But after a rough January, when Chipotle had to remove pork (as in the popular carnitas option) from a third of its restaurants because of concerns over animal welfare, Co-Chairman and Co-CEO Steve Ells was confident about his company’s mission and business model. Its competitors could learn a lot from that hour-long call.

The earnings call started almost immediately with Ells confronting last month’s crisis, which could cost the company up to $2 million in sales. Last month many analysts insisted that Chipotle’s commitment to sustainable pork — and all meat for that matter - -and animal welfare would hurt the company in the long run. But Ells hardly sounded as if he were on the defensive. If anything, it was more of a lecture on why a business should do good and do right. “We have made it our mission to change how people think about, and eat, fast food,” Ells said as he launched into his segment of the call.

So, why would a company with 1,800 restaurants and counting take such a hit on the ledger? According to Ells, what many viewed as a crisis was a time for the company to stand its ground even more. “Choosing to suspend the supplier meant that we would not be able to supply carnitas to about one-third of our restaurants,” he said. “While we could have chosen to replace this supply with pork from conventionally-raised pigs, we decided not to because most conventionally-raised pigs are subjected to conditions that we find unacceptable.”

Ells then continued with what sounded like an Animal Welfare 101 lecture, explaining how pigs raised conventionally are almost never outdoors, cannot roam outside and have no bedding — while antibiotics and other treatments compensate for harsh treatment and cause the pigs to grow unnaturally. “Customers are applauding our commitment to our vision, thanking us for standing on principle, commending us for taking action against the inhumane treatment of animals, and congratulating us for standing by our business values,” he said.

Ells then made his case about the benefits of sustainably-sourced meat, dismissing January’s supplier fiasco as a disruption that can help the company strengthen its supply chain — and continue to grow in the long run. Those values echoed throughout the company’s supplier base, from the drive to buy only no-till or organically-grown beans to the commitment to source locally-farmed produce as much as possible.

Indeed, customers are responding to Chipotle’s stand, and they are voting enthusiastically with their feet — walk by your local Chipotle at the lunch hour and see if you can even get a chair. While fast food chains of yesterday struggle to get customers through the door, Chipotle is winning hands-down with younger customers — where the real battle is. Teens, millennials, Generation X — Ells listed a bevy of statistics from surveys that show consumers are more discerning about where their food comes from.

To any business school professor or executive who says the point of a business is to only provide value to shareholders while dismissing any notion of social responsibility, he or she should listen to the first 10 to 15 minutes of Chipotle’s business call and take notes. Chipotle is a compelling example of how a company can have a conscience and yet continue to reap success.

Image credits:Proshob

Based in California, Leon Kaye has also been featured in The Guardian, Clean Technica, Sustainable Brands, Earth911, Inhabitat, Architect Magazine and Wired.com. He shares his thoughts on his own site, GreenGoPost.com. Follow him on Twitter and Instagram.

VF Corp. Looks to Cut Chemicals in Textile Manufacturing

Back in 2011, Letitia Webster, now senior director of global sustainability for VF Corp., was asked to start and lead the company's global sustainability program. This involved creating a framework to align sustainability efforts across the corporation’s 30 brands, including The North Face, Timberland and Vans.

To accomplish this task, Webster looked closely at waste, energy and water issues connected to the production of the brands’ diverse products. During her assessment, she noted the great environmental impact of the chemicals used throughout the manufacturing process. That observation sparked the eventual creation of CHEM-IQ, VF’s new chemical management program launched with pilot factories in 2013 and set to scale across the corporation’s entire supply chain this year.

For a company that produces more than 500 million units a year – many of which are high-performing technical products designed for professional athletes, which require robust chemistry to meet wind-, water- and odor-resistance needs – moving the needle on how VF and all of its suppliers manage chemicals was not a lone undertaking.

The CHEM-IQ program was developed in partnership with University of Leeds and University of Massachusetts, Lowell, with support from the Natural Resources Defense Council (NRDC) and technical service provider Modern Testing Services. It evaluates chemicals used at the mill level – before they enter the manufacturing process – and identifies toxins present in some dyes, flame retardants, and water, stain and wrinkle repellents that could harm people and the environment.

Many chemicals used to make our favorite T-shirts, jeans and jackets are ultimately discharged as wastewater into bodies of water around the world – once at the manufacturing stage and many times over the product’s lifetime when consumers wash their clothes at home. Some of these chemicals make their way into rivers, seas and oceans and can harm aquatic life, not to mention humans.

“When the industry moved to Asia, water issues went by the wayside,” Webster explained. “[With CHEM-IQ], we’re trying to build a platform that takes into consideration all regulations across the line and create something that becomes a new norm. If we find a chemical that might be an endocrine disrupter, we will eliminate it.”

As an $11 billion global apparel and footwear business with an international portfolio of brands, VF’s chemical management program is not only focused on accelerating the use of safer chemicals throughout its supply chain, but it is also hoping to influence global industries. Taking a cue from The North Face’s “gift” of its Responsible Down Standard to industry group Textile Exchange, VF hopes to gift CHEM-IQ to an external group and spur transformational change in chemical management across sectors.

“It’s a very easy business case: It’s not expensive. The mills pay for the testing, and we got [the testing] down to $50 per chemical, which is really manageable. The benefits far outweigh any costs,” Webster said. “We want to make sure we’re moving down the path of better, smarter, safer chemistry … It does the industry no good if it’s just a VF program.”

Tools to evaluate chemical ingredients in apparel products are not new to the industry. The Sustainable Apparel Coalition’s Higg Index, released in 2012, includes chemical management components, as does the chemical management guide Chemicals Management Module (CMM). Last year, the American Apparel & Footwear Association (AAFA) launched its own Web-based collaboration tool to encourage industry-wide information exchange about chemical management practices.

Beyond providing a mechanism to evaluate chemicals, CHEM-IQ connects suppliers to a low-cost chemical testing system to screen out toxins from supply chains.

Corporate initiatives to target chemicals management, as a part of sustainability strategy, have arisen partly in response to a rising tide in advocacy and consumer concern about the chemical makeup of everyday products. Greenpeace’s ongoing Detox Fashion campaign, for example, has increasingly raised consumer awareness of hazardous chemicals in our clothes. The campaign has challenged big names such as Adidas, Nike and Zara to eliminate hazardous substances from their supply chains and products.

Online and mobile tools, such as GoodGuide, also empower consumers with information about products’ overall health, environmental and social performance -- encouraging the public to vote with their dollars.

With CHEM-IQ, VF is not only turning a potential reputational risk into an innovative opportunity, but it is also reassuring consumers about the company's products and heartening other industry players to do the same.

For more information on the CHEM-IQ program, check out the infographic below.

Image credit: Flickr/marcohk

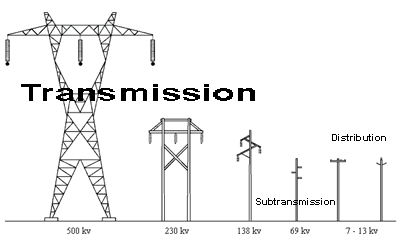

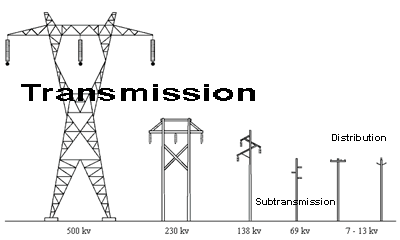

Grid, Mining Projects Highlight Energy Storage Potential

Two recent announcements highlight the potential for advanced energy storage solutions to deliver financial savings to business and consumers, as well as address environmental and socioeconomic issues.

According to proponents, the proposed energy storage projects – one in northeastern Pennsylvania and the other in northern Quebec – would significantly reduce fossil fuel use, accelerate integration of renewable energy and enhance resiliency of the power grid.

In Pennsylvania, Beacon Power is proposing a 20-megawatt power storage facility that would employ 64 flywheel systems, measuring 7 feet each, to store and feed electricity into the PJM power grid. A regional transmission organization, PJM is responsible for wholesale electricity transmission for some 61 million people across 13 U.S. states and the District of Columbia.

Up in northern Quebec, multinational mining giant Glencore has taken delivery of a lithium-ion (Li-ion) battery storage system that it expects will reduce diesel consumption at its Raglan nickel mining complex by 35 to 50 percent. Electrovaya's Lithium-Ion 2.0 energy storage system will also enable Glencore to expand its use of wind power at Raglan, compounding the benefits the company expects to realize by incorporating advanced energy storage and integrating it with wind power generation.

Mining, renewable energy and energy storage

Valued at $70,000, the Lithium-Ion system Electrovaya has delivered to Glencore's Raglan nickel mining complex is able to “accept and store energy from all sources, including diesel generators, solar and wind,” PVTech's Andy Colthorpe reported on Feb. 2. Glencore has already installed a 3-megawatt wind turbine at the Raglan site. The company is considering installing an additional 9 to 12 MW of wind energy capacity, which could cut the mine's diesel consumption by 40 percent, Mining Weekly reported.

Diesel consumption at the Raglan mining complex runs around 50 million liters annually, according to PVTech's report. Glencore is looking to the Raglan project to assess the integration of wind power and energy storage at its other mines around the world.

Flywheels for grid frequency regulation

It's high-tech flywheels -- rather than Li-ion batteries -- that will store energy for frequency regulation on the PJM grid if Beacon Power's proposed project comes to fruition, according to a report from the Scranton Times-Tribune's Jon O'Connell. The proposed site is located near the Valley View Business Park owned by Scranton Lackawanna Industrial Building Co.

Encased in 7-foot-tall carbon fiber cylinders, each unit of Beacon Power's flywheel energy storage solution is capable of storing as much as 15 minutes worth of electrical power at maximum capacity. At the proposed site in northeastern Pennsylvania, that translates into 5 megawatt-hours of energy -- which would help PJM maintain voltage across the mid-Atlantic grid within tolerable limits.

“This is not like your typical power plant,” Beacon development consultant David Stoner was quoted in the Times-Tribune's report. “We don’t burn any fuel; we have no emissions; we use no water.”

Back in 2008, PJM had just 1 MW of power storage capacity available. Today, that's increased to 85 MW, and plans are under way to raise that nearly 250 percent in coming years, PJM senior business solutions analyst Scott Baker told the Times-Tribune.

*Image credits: 1) U.S. Occupational Safety & Health Administration; 2) Glencore; 3) Beacon Power

H&M CEO: Reducing Consumption Isn't the Answer

The CEO of one of the world's largest clothing retailers thinks that we will be heading the wrong way if we reduce consumption to ward off climate change.

Karl-Johan Persson, who runs the Swedish multinational Hennes & Mauritz (H&M), suggested in an interview with the Guardian that, "If we were to decrease 10 percent to 20 percent of everything we don’t need, the result on the social and economic side would be catastrophic..." Cutting back precipitously would increase worldwide unemployment and poverty, he argued. The challenge, said Persson, is "doing it in a way where you still can have economic growth and jobs creation, while finding the innovations that can limit the damage to the environment.”

The article in the Guardian was noted as containing content that was paid for by H&M. Still, it brings up some valid points about manufacturing challenges in today's retail sector.

In a way, Persson's statements aren't that far away from prevailing attitudes of some of the more popular U.S. clothing manufactures. Levi-Strauss & Co., Patagonia and other clothes producers we've mentioned here have vigorously supported a "circular" economy in which products are used, recycled or reused -- and hopefully most or all of their ingredients are kept out of the landfill. Levi-Strauss & Co.'s recycled denim and Patagonia's Worn Wear initiative both exemplify this idea. So does H&M's own recycling initiative, which issues vouchers in exchange for returned, pre-loved clothing.

But in a day and age when most of our clothes are manufactured through contracted labor in developing nations, the challenge is not only how to use those manufacturing resources most sustainably, but also how to us them in a way that is socially beneficial.

And, unfortunately, Persson's company has the experience to back this statement up. H&M is well known for its philanthropic efforts and its innovative sustainability initiatives. But it has also been embroiled in embarrassing labor issues that have brought workers' rights to the fore.

As one of the world's largest purchasers of Bangladesh-produced clothing, it's been accused of contracting with sweatshops that were audited for improper employment practices. These audits became public after the singer Beyonce agreed to represent the label.

Persson has also made sure that H&M addressed that issue. His company has been unabashed about its use of Bangladesh labor, acknowledging that the country is "one of our most important production markets." To that end, he has worked with political leaders and business owners to push for better labor conditions and, in 2013, pledged a living wage for H&M's Bangladeshi and Cambodian workers. Even though it was not one of the companies that paid for labor at the Rana Plaza, Bangladesh facility at the time of its disastrous collapse, Persson said the company felt that it was important to set an example by establishing better wages.

But ensuring fair labor practices is still only part of the answer for an industry that must, in essence, not only retrain its workers on how to be sustainable, but also gently encourage customers to be more proactive in contributing to that circular economy. The clothing industry of the future will rely on new technology to ensure that products can be repurposed if not recycled.

Popular initiatives like Runway, a Michigan-based competition that encourages fashion designers to come up with unique ways to repurpose old or worn clothing, reflect this concept. But for the large, high-scale clothing retailers like H&M, it will take bolder and leaner concepts that can not only address ingenuity and style, but also the commercial needs of a labor market that, like its employers, need to stay in business to support a sustainable, smarter economy.

Image credit: Bangladesh clothing factory - Tareq Salahuddin

USGBC Announces the Top 10 States for LEED in 2014

True, top 10 lists are often subjective, and data can be massaged to get the list we want. But they are still a way to see how our companies or geographic regions are performing compared to others — from solar, to corporate sustainability, to overall market trends and -- why not -- even sustainable breweries.

Now, the U.S. Green Building Council (USGBC) is getting into the act, giving us a list of the top 10 LEED states in green building performance.

USGBC crunched the data by tallying up the total square footage of commercial and residential spaces that were LEED-certified during 2014. That total was then divided by each state’s population based on 2010 U.S. census data. The results offer rankings based on per-capita LEED space per resident, the metric USGBC has used for the fifth year in a row.

If it were a state, the District of Columbia would blow all 50 states out of the water, with more than 100 certified LEED projects. Washington, D.C. has bragging rights with a whopping 29.44 square feet of certified green building space per resident — almost nine times the amount of the leading state.

And that state would be Illinois, which tops the list for the second year in a row. It logged 174 projects, one of which is the renovated silver-certified Aon Center (originally the Standard Oil Building), at one time the world’s tallest marble-clad building and the third tallest building in Chicago. Illinois is the only state to make the annual top 10 list every year, along with Colorado, since USGBC first launched these rankings in 2010.

Colorado hardly had a shabby year in the LEED world, only narrowly edged out by Illinois, by 3.31 to 3.15 square feet of LEED-certified space per resident. One of the more stunning projects that achieved LEED Platinum Certification in the Centennial State is the Morgridge Family Exploration Center at the Denver Museum of Nature and Science. The 126,000-square-foot space, which hosts children’s science exhibits along with special exhibition space, uses 50 percent less energy than conventional buildings of the same space and incorporates a bevy of solar technologies.

Maryland and Virginia are ranked next, buttressing the mid-Atlantic region as the stronghold of green building within the U.S. Massachusetts rounds out the top five. Not surprisingly considering their ongoing investment in solar power, Hawaii and California are ranked next on the list.

Newcomers to USGBC’s list are two states with their share of water challenges, Georgia at No. 8, and Arizona, which ties with New York at No. 10. Minnesota, which made news last year for becoming the first state to set a “value of solar” tariff, comes wedged between at No. 9.

Overall, it was a successful year for USGBC and LEED, which saw the highest average of LEED certified space per resident since 2010. More than 1,600 projects, representing 251.7 million square feet of space, scored LEED certification in 2014. Over 4,500 properties worldwide earned a level of certification last year as well.

While LEED has attracted its share of critics, overall it is a step forward for sustainable construction and design, and it allows property managers and tenants to seamlessly compare energy and water efficiency between LEED-certified and conventional buildings.

Image credits: Ryan Dickey; Orcutt | Winslow

Based in California, Leon Kaye has also been featured in The Guardian, Clean Technica, Sustainable Brands, Earth911, Inhabitat, Architect Magazine and Wired.com. He shares his thoughts on his own site, GreenGoPost.com. Follow him on Twitter and Instagram.

Japanese car brands lead way in emissions reductions

Japanese automobile manufacturer Nissan tops a new league ranking car brands on their emissions reductions.

The research has been compiled by climate change organisation CDP to rank auto manufacturers in a league table based on a number of different emissions-related metrics. CDP believes that taken in aggregate, the metrics could have a material impact on a company’s earnings in a global auto market where emissions regulation is tightening. Fleet emissions regulation now covers more than 80% of global auto sales, it maintains.

Toyota ranked in second place and Mazda in fourth. French company Renault gained third place. CDP say the brands ranked highly due to leadership in fleet emissions reduction and advanced vehicles which include battery electric vehicles (BEVs), plug-in hybrid electric vehicles (PHEVs) and fuel cell vehicles.

CDP emphasises that the rankings are not intended to identify definitive winners and losers for investment purposes, but rather to indicate strategic advantage in an industry where there is a significant regulatory impact on all major auto markets.

Appearing the near the bottom of the table, Hyundai scored D-grades for its fleet emissions in the EU, US and China, and also for its advanced vehicle range. General Motors and FCA (Fiat Chrysler Automobiles) were noted as the worst performers for CDP's fleet emissions grade and Tata Motors is the bottom-ranked company of those disclosing to CDP. This was partly due to an incomplete response to CDP’s questionnaire, together with the fact it has not released an advanced vehicle.

Access the report, ‘No room for passengers: are auto manufacturers reducing emissions quickly enough?' here.

Walmart, Target, Walgreens, GNC Accused of Selling Fake Supplements

Despite their enduring popularity and sketchy health claims, dietary supplements are not regulated to the degree food and drugs are by the U.S. federal government.

That is largely thanks to Utah Sen. Orrin Hatch, who wrote the 1994 Dietary Supplement Health and Education Act (DSHEA). Past efforts to amend the law so that supplements could be subjected to some degree of scientific testing have been blasted as attempts to “overregulate” the multi-billion dollar industry. But critics of the industry will be calling for more regulations after what has been discovered at large retail chains including Walmart, Target, GNC and Walgreens.

According to cease-and-desist letters sent by New York Attorney General Eric Schneiderman, at least five dietary supplements sold at these stores have been mislabeled. Instead of St. John’s Wort, ginseng, garlic, Echinacea and saw palmetto, DNA testing revealed consumers were instead swallowing a bevy of placebos, and even allergens, including rice, wheat or dracaena — a species of tropical houseplant.

The investigation was sparked by a 2013 investigative report in the New York Times that alleged many supplements on the market were no more than powdered rice and weeds. The article quoted a Canadian university study that used DNA barcoding to reveal that many of the supplements researchers tested were of poor quality, highly diluted or even contaminated. A Department of Health and Human Services (DHH) study completed around the same time found that misleading medical claims were also frequently made by supplement manufacturers.

In the meantime, the New York Attorney General’s office has contacted the four companies’ CEOs, asking for documentation related to the sourcing of the supplements in question. Each letter reflects a disturbing trend: Only a small minority of supplement samples taken from different New York store locations revealed plant DNA matching the product label. The vast majority either revealed different plant material or no plant DNA at all, suggesting many of these products are so over-processed that any health benefits were lost during their manufacture.

The fight over the regulation of supplements has dragged on for a generation, and considering the current makeup of Congress, it is doubtful any progress on what has turned a promising industry into a nationwide scam will be made anytime soon.

So, what are consumers to do? They can start with educating themselves by reading up on websites such as those run by NSF or ConsumerLab.com. One startup, LabDoor, has made progress on testing vitamins and supplements on the market and has thousands more products in the pipeline. But do not expect an industry that has profited from dubious scientific claims and a complete lack of transparency for years to give in anytime soon.

Image credit: FDA

Based in California, Leon Kaye has also been featured in The Guardian, Clean Technica, Sustainable Brands, Earth911, Inhabitat, Architect Magazine and Wired.com. He shares his thoughts on his own site, GreenGoPost.com. Follow him on Twitter and Instagram.