By Jeff Yorzyk

We have all heard the old axiom that states, “What gets measured gets managed.” But sustainability practitioners are frequently confronted with a tough question: “How do I measure that?” Furthermore, the definition of sustainability metrics also runs into the challenge of recognizing how the capital “S” of Global Sustainability distills down to specific sustainability priorities for any individual organization. Life Cycle Thinking is an approach that helps answer both of these questions.

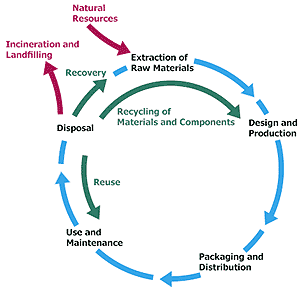

Life Cycle Thinking is defined by the United Nations Environmental Program's Life Cycle Initiative as “going beyond the traditional focus and production site and manufacturing processes to include environmental, social and economic impacts of a product over its entire life cycle.”

While the quantitative process of Life Cycle Assessment is not explicitly required to do this, it is a strong supporting tool. The fundamentals of both Life Cycle Thinking and Life Cycle Assessment include mapping the value chain and identifying inputs and outputs at each stage – an exercise that takes an organization well beyond the “boundaries” it typically considers for its operations.

Mapping the value chain

Mapping a value chain can seem daunting at first, but with the help of a team familiar with the product or service in question, it can be reduced to a few hours (or less) of brainstorming on a white board. By starting where you are in the value chain (for example “retail” or “final assembly”), the group can easily identify upstream and downstream partners (i.e. vendors and customers). Each step further away gets a little more challenging, but the team should be able to make assumptions and take follow-up actions to flesh out the map over time. Key inputs and outputs (materials, energy sources, emissions and products), and/or key issues known or suspected (hazardous waste generation, human rights issues, etc.) should be identified at each link of the value chain.

Value chain mapping can be seen as an iterative process, where detail and depth of understanding is added over time. It surfaces key issues related to a product or service that may not be visible within the commonly considered “boundaries” of an organization's operations by explicitly going beyond that traditional focus. The mapping step allows potential issues and opportunities to be identified and flagged for investigation, focusing future efforts on the most important items. When this map is assessed in relation to the larger suite of (capital “S”) Global Sustainability challenges, it can provide deep insight for understanding an organization's sustainability priorities. It can also provide insight into where the organization can control or influence those key issues, and how.

Translating sustainability priorities into performance metrics is the second trick. Two common first sources for consideration include (a) what competitors may be reporting publicly, and (b) publicly available guidance from groups like the Global Reporting Initiative and Global Environmental Management Initiative.

Often, the key metrics will present themselves along with key issues and opportunities observed in the investigation of the value chain. Generally speaking, metrics are used to measure performance, drive improvements and help businesses focus their people and resources on what’s important. Taking a Life Cycle approach, indicators can also be developed to drive improvement and focus activities across the entire value chain. This requires careful attention to metrics related to value chain influencing factors, such as product design (material choices and production requirements), purchasing policy and value chain engagement.

A closer look at environmental performance indicators

Ideally, metrics tell us more about the future than the past. ISO 14031 (Guidelines on Environmental Performance Evaluation) provides for establishment of measurable and verifiable performance indicators that are appropriate to any public or private enterprise, defining Environmental Condition Indicators (ECI), Operational Performance Indicators (OPI) and Management Performance Indicators (MPI). The strength of this approach is that these indicators represent three levels of control – low (ECI), medium (OPI) and high (MPI). These can be leveraged beyond environmental indicators to include Social Condition Indicators (SCI) and the corresponding OPI and MPI elements.

ECIs represent the ambient environment, which has a large number of influencing factors largely outside of an individual organizations control. OPIs represent the direct performance of the organization and generally relate to inputs and outputs of the organization, which are within the organization's span of influence (if not control). MPIs – an often overlooked set of metrics – represent the organization's efforts to control the inputs and outputs, such as training, product and procurement scorecards, supply chain performance evaluations and waste minimization programs, all of which are fully within the organization's span of control. Conceptually, MPIs (direct control) allow an organization to strongly influence OPIs, in the attempt to make a positive contribution to global ECIs.

The key to this approach is that MPIs, which are in full control of the organization, can be actively managed. When developed using a Life Cycle perspective, MPIs can have a tremendous impact on OPIs at both the operating and value chain level, and can be viewed as “forward looking” in that regard. Examples of this would be product, procurement and supply chain scorecards. ECIs and SCIs, in turn, then create context for the level of management attention that need to be paid to activities that impact the organization's sustainability priorities (MPIs). Bottom line, organizations that establish and track indicators at all three of these important levels using a Life Cycle perspective maximize the benefits to themselves, and to the world they operate within.

At the upcoming ISSP Conference 2014, these issues and more will be explored in a break-out session about Life Cycle Assessment led by Jeff Yorzyk, Senior Asset Sustainability Specialist at Cardno, Inc., and Tad Radzinski, co-founder and president of Sustainable Solutions Corp.

Image credit: "Greening the Economy Through Life Cycle Thinking" report by United Nations Environmental Program Life Cycle Initiative.

Jeff Yorzyk is a member of ISSP’s Board of Directors. ISSP Conference 2014 will be held November 12-14 in Denver. For more information, visit http://www.sustainabilityprofessionals.org/

TriplePundit has published articles from over 1000 contributors. If you'd like to be a guest author, please get in touch!