Many of us enjoy a cold brew from time to time, but beer’s surging popularity worldwide has resulted in this beverage sporting a massive water and carbon footprint. More global brewing companies and local craft beer makers are aggressively working to mitigate their environmental impact, while ensuring that this industry can stay economically viable in a world where water is becoming scarcer and energy prices can surge with little notice. All that sanitizing, pasteurizing and, of course, what ends up in the can or bottle requires much water and therefore energy. One company has taken a large step in neutralizing its beer’s footprint with the announcement that one of its most venerable breweries is now a carbon-free operation.

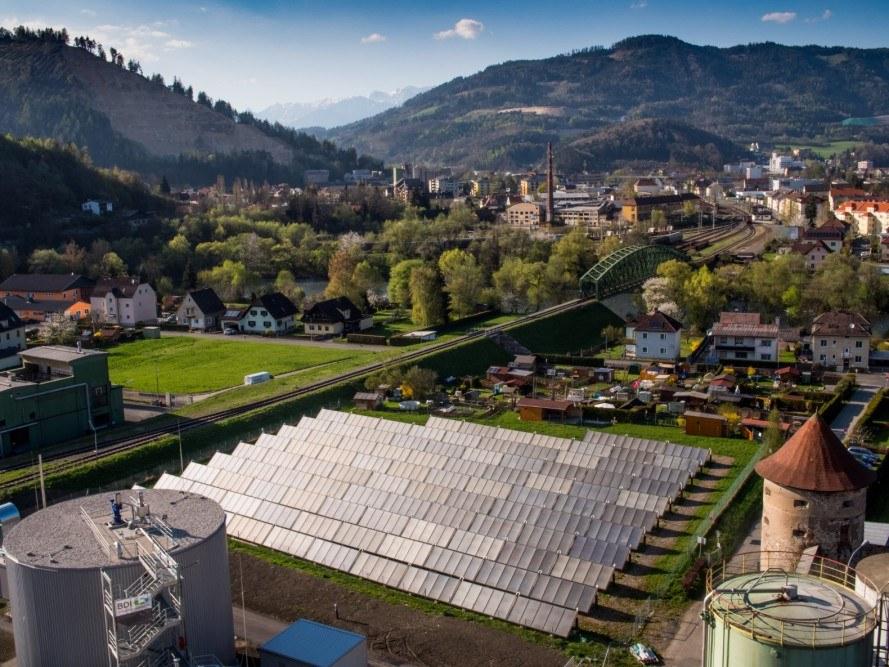

Earlier this week, Heineken cut the ribbon for what the brewing giant says is the world’s first “major zero-carbon brewery.” The Göss Brewery, located in the mountain town of Leoben in central Austria, is one of Heineken’s most prized properties. The brewery claims a history reaching back to 960 A.D., when monks in a local abbey started churning out hoppy suds that eventually became one of Austria’s most popular brands of beer.

Heineken eventually acquired a majority stake in the company that owned Gösser Beer in 2003. Shortly afterward, Heineken started to incorporate more renewable sources of energy to power the modern brewery’s operations, including hydropower, district heating from biomass and solar. According to Heineken, having Göss Brewery run on 100 percent renewables makes an already highly efficient and automated operation even more economically viable.

“Not being dependent on energy sold on the open market protects the brewery from price fluctuations, and therefore saves money in the long-term,” said Michael Dickstein, director of global sustainable development at Heineken, in an emailed statement to TriplePundit. “The combination of energy the brewery now runs on will provide it with energy for at least the next 15 years, which provides financial stability to the brewery.”

Prior to weaning Göss Brewery off the local conventional power grid, Heineken estimated that the carbon emissions from the 156-year-old brewery reached 3,000 tons a year. With its retrofit complete, the company insists that the plant’s annual emissions will tally exactly zero.

To eliminate those emissions, Heineken embarked on a plan that incorporated both renewables and energy-efficiency measures. Sources of energy that include biogas generated from the brewery’s spent grain fermentation tank, as well as biomass generated from a nearby sawmill, contribute to the plant’s power needs. Up to 5 percent of the brewery’s power is now provided by a 16,000-square-foot rooftop solar installation. In addition, waste heat resulting from the plant’s brewing process, and a modernized boiling system, help the plant operate more effectively.

In addition to having a zero-carbon operation, Göss Brewery is also nudging toward more of a closed-loop system. For years, spent grains used in the brewing process were distributed to local farms for animal feed, which is the standard practice within the brewing industry. Now, however, the brewery’s managers use those grains to heat the plant’s boilers — and the resulting waste is then sent to local barley farmers, who grow the grains that Heineken then churns into additional batches of Gösser Beer.

Heineken also says that the brewery now sources all of its raw materials from within Austria. Such steps are integral to what Heineken says is its pledge to reduce the company’s carbon emissions by 40 percent within its entire global production operations by 2020.

Such a plan provides a case study for how sustainability professionals can reduce a company’s environmental impact while improving his or her company’s financial performance. But also important is imparting this information to consumers. Heineken has a plan to label four brands as “Brewed by the Sun” as a way to show consumers, who are increasingly demanding that companies become more responsible in their operations, that the beers they are drinking have less of a carbon footprint.

Gösser, along with Heineken brands including Tiger, Birra Moretti Baffo D’Oro and Wieckse, now sport this label or will in the coming year. If they are wise and follow the lead of their customers, watch for Heineken’s competitors to start similar campaigns soon.

Image credit: Heineken

Leon Kaye has written for 3p since 2010 and become executive editor in 2018. His previous work includes writing for the Guardian as well as other online and print publications. In addition, he's worked in sales executive roles within technology and financial research companies, as well as for a public relations firm, for which he consulted with one of the globe’s leading sustainability initiatives. Currently living in Central California, he’s traveled to 70-plus countries and has lived and worked in South Korea, the United Arab Emirates and Uruguay.

Leon’s an alum of Fresno State, the University of Maryland, Baltimore County and the University of Southern California's Marshall Business School. He enjoys traveling abroad as well as exploring California’s Central Coast and the Sierra Nevadas.