Hydrogen fuel cell vehicles are having a tough time competing with their battery-based cousins in the race to dominate zero-emission personal mobility on the open road. But the business community is discovering one area in which fuel cells have a clear advantage. That would be the logistics sector, where moving goods around warehouses is a delicately timed race against the clock.

In the latest development, Toshiba is touting a new transportable, renewable hydrogen-based emergency generator. The tech giant hopes to demonstrate the generator as the basis for permanent hydrogen fueling stations that could serve forklifts and other vehicles at warehouses, factories, airports and elsewhere.

That's good news for fuel cell electric vehicle fans. Flipping the hotly competitive logistics sector to hydrogen would mean that R&D will develop apace, helping to push lower costs and higher efficiency into the EV market.

Toshiba and renewable hydrogen

Toshiba is starting off on the right foot when it comes to hydrogen fuel. Instead of sourcing hydrogen from natural gas, Toshiba developed its H2One transportable hydrogen system as a renewable energy product.

The company deployed a large-scale version of H2One last year in the city of Kawasaki, Japan, to demonstrate how the system can operate both as an emergency source and as a way to relieve the grid from peak-use spikes.

Here's the rundown from Toshiba:

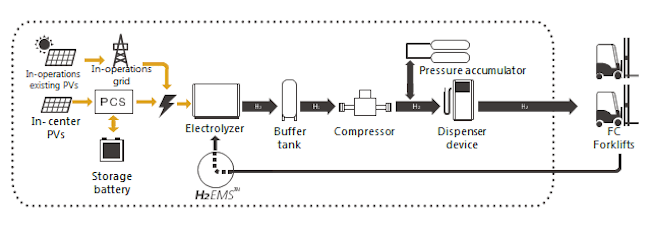

"H2One combines photovoltaic installations, storage batteries, hydrogen-producing water electrolysis equipment, hydrogen and water tanks, and fuel cells," Toshiba says. "Electricity generated from the photovoltaic installations is used to electrolyze water and produce hydrogen, which is then stored in tanks and used in fuel cells that produce electricity and hot water."

As an emergency power source, the Kawasaki installation can provide electricity and hot water for around 300 people for about a week.

The ultimate goal of the demo project is to develop a renewable hydrogen system that can operate independently as a long-term strategy for local communities to go off-grid.

Toshiba introduced a scaled-down version of the system earlier this year that can be transported easily by two 4-ton trucks for mobile disaster response. As with the larger version, the system "splits" water using an electrical current that is powered by solar energy.

The mobile system illustrates how Toshiba is continuing to improve on H2One:

"The H2One Truck Model’s hydrogen storage tank is made with a new hydrogen storage alloy that achieves much improved high-density storage. This advance contributes to system mobility and improved flexibility," the company says.

Renewable hydrogen and logistics

Toshiba notes that renewable hydrogen fuel cells easily beat diesel generators as a disaster-relief energy supply. They are quiet and non-polluting, and their fuel can potentially be scavenged on-site rather than depending on fuel convoys.

Those advantages are also true of battery-powered generators that are charged from solar or wind energy.

The zero-emissions angle makes both batteries and fuel cells ideal for the logistics field. Zero-emission vehicles are especially important for warehouses and other confined spaces. They are also becoming increasingly important at seaports and other congested transportation hubs, where improving outdoor air quality is imperative.

When it comes down to the factors of time and space, fuel cells do have an advantage over batteries. A fuel cell forklift can be refueled in a few minutes. That relieves facility managers from the headache of orchestrating operations around battery recharge times and swap-outs. It also frees up the space that would otherwise be devoted to battery charging and storage.

Zero-emissions forklifts

That brings us to Toshiba's latest announcement, the Hydrogen Application Center. Located at Toshiba's Fuchu Complex, the new facility consists of a H2One system specially designed as a fueling station for hydrogen fuel cell forklifts.

Toshiba has big plans for the new facility.

Mr. Hiroyuki Ota, project manager of Toshiba’s Energy Systems and Solutions (ESS) company, noted: “The Hydrogen Application Center is a stepping stone to building a new business. We will utilize experience and know-how gained from the Hydrogen Application Center to develop and deliver a H2On for use in factories, warehouses, logistics facilities and airports."

That's just for starters. Toshiba wants the Fuchu Complex to be viewed as "the realization of a carbon-free society where hydrogen energy is widely used," Mr. Ota said.

Along with H2One, the facility deploys Toshiba's companion hydrogen energy management system, the H2EMS. Among other efficiencies, the system optimizes refueling, so space for hydrogen storage can be kept to a minimum.

Back in 2011, TriplePundit took note of the important role that logistics will play in decarbonization. It looks like Toshiba is determined to lead the trend.

Toyota also has big ambitions for the zero-emissions economy of the future, so stay tuned for more on that.

Images courtesy of Toshiba

Tina writes frequently for TriplePundit and other websites, with a focus on military, government and corporate sustainability, clean tech research and emerging energy technologies. She is a former Deputy Director of Public Affairs of the New York City Department of Environmental Protection, and author of books and articles on recycling and other conservation themes.