When you think of Ford Motor Co., think of a company that is striving to reduce its waste sent to landfills. A good example is its Research & Engineering Center in Dearborn, Michigan, which isn’t sending its waste to a landfill. The 720-acre center has over 12,000 employees in 34 buildings. In other words, it generates a lot of waste.

The R&E Center spent almost three years achieving landfill-free status. It did so first by identifying waste streams and categorizing them from smallest to largest. Then, waste managers and environmental engineers found ways to avoid sending waste streams to landfills while not increasing waste management costs. The R&E Center now diverts 230,000 pounds of waste from landfills each year.

“Our global waste strategy commits Ford to reducing waste-to-landfill, and we have made great progress at our manufacturing plants,” Andy Hobbs, director of Ford's environmental quality office, said in a statement. “We are now extending this effort to our office and research facilities, and are proud to recognize the Research & Engineering Center for sending zero waste-to-landfill.”

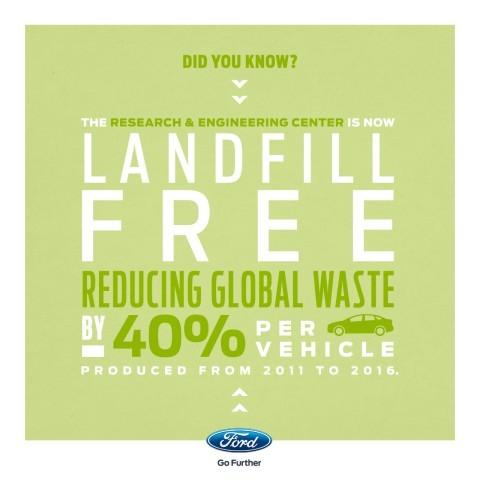

The R&E Center’s achievement helps Ford come closer to its goal of reducing global waste-to-landfill by 40 percent per vehicle produced from 2011 to 2016. The automaker has cut global waste sent to landfills by 50 percent per vehicle over the last five years. Thirty of its facilities don’t send any waste to landfills, including all of its Canadian and Mexican manufacturing plants.

Ford’s most recent sustainability report highlights what it has done to reduce waste sent to landfill. One method is the use of waste-reduction technologies and programs in its plants. Specific examples include:

- The company implemented a minimum quantity lubricant (MQL) machining process (also called “near-dry machining“) which reduces waste by over 80 percent for each engine it produces. It also saves water and oil. The process is now implemented in six plants in North America, Asia and Europe.

- Five of its plant in the U.S. send paint sludge to DTE Energy for recycling, eliminating over 1,300 tons of waste in 2014 that would have been sent to a landfill.

- Last year, two of its plants in China started using a non-landfill method for wastewater treatment plant sludge that removes 2,800 metric tons of waste from landfill a year.

- At many of its plants, Ford has reduced packaging waste by using returnable and reusable packaging materials.

- At U.S. and Canadian facilities, grinding swarf is recycled which eliminates up to 3 million pounds of waste sent to landfill every year.

Image credit: Ford

Gina-Marie is a freelance writer and journalist armed with a degree in journalism, and a passion for social justice, including the environment and sustainability. She writes for various websites, and has made the 75+ Environmentalists to Follow list by Mashable.com.