The energy-efficiency sector is creating new green jobs hand over fist, and the U.S. Department of Energy is getting ready to stir the pot with assistance from the iconic company GE. The public-private partnership centers around an energy-efficient, "ultrasonic" clothes-drying system that uses 70 percent less energy than conventional clothes dryers.

Aside from reducing household utility bills, the new technology offers some great potential green business opportunities in the commercial laundry sector.

Clothes dryers and energy efficiency

The DOE's Oak Ridge National Laboratory in Tennessee is known for its high-tech research, from solar cells to nuclear energy and 3-D printing. So, it's fair to ask why Oak Ridge is engaged in the seemingly mundane field of household appliances.

Actually, household appliances have become a major focus area for the Energy Department, and its 2014 Roadmap for Next-Generation Appliances explains why:

Residential appliances such as refrigerator/freezers, dishwashers, laundry equipment, and cooking equipment account for over 12 percent of U.S. residential sector primary energy consumption.The appliance sector has seen substantial innovation in recent years; however, energy efficiency measures, while significant, have generally involved incremental improvements to meet new DOE efficiency standards. Little research has focused on radical innovations that might dramatically reduce energy consumption.

Clothes dryers alone make a significant contribution to U.S. electricity use. According to the Energy Department, almost 80 percent of American households include a clothes dryer, and collectively they account for about 4 percent of total residential electricity use.

As for committing federal R&D dollars to common household products, you can see a similar approach in the department's administration of energy-efficiency requirements for household lighting. In addition to administering federally mandated energy-efficiency improvements, the Energy Department partnered with the private sector on LEDs and other next-generation, high-efficiency lighting technologies.

The urgency of an energy-efficiency breakthrough for clothes dryers becomes apparent when you factor in population growth and the expansion of urban areas, where there is limited opportunity for solar-powered clothes drying (aka a laundry line and clothespins).

Building a better clothes dryer

The basic idea behind the new clothes dryer efficiency research is to remove heat from the clothes-drying process, and replace it with high-frequency vibrations. In effect, the ultrasonic vibrations "atomize" water in the fabric. Instead of being released as hot steam, water exits the fabric in the form of a cool mist.

So far, Oak Ridge and GE have proven the new technology in principle. The plan is to scale it into a working device by the end of this summer, with the expectation that the new dryer will take less than half the normal time and use 70 percent less energy.

All else being equal, the energy savings alone is a strong selling point in terms of reducing household utility bills. Add the convenience of a significant reduction in drying time, and that makes the attraction even stronger.

Those two factors also work strongly in favor of adoption in the commercial sector. Public laundries, for example, would see a higher customer turnover per machine while reducing bottom-line operating costs. The high turnover/lower cost equation would also apply to institutional laundries.

The new technology provides an additional, significant sustainability benefit by putting much less wear and tear on clothing than heat drying. That's a bottom-line plus for the many companies, institutions and agencies that employ uniformed personnel.

Reducing the amount of lint for disposal also contributes to overall sustainability, and the release of water as a cool mist may provide a cost-effective opportunity for water reclamation.

Dude, where's my piezoelectric transducer?

The key to the new technology is a device called a piezoelectric transducer, which sounds like it could be second cousins with a continuum transfunctioner except that, unlike the continuum transfunctioner, piezoelectric transducers are real.

Piezoelectricity refers to the ability of certain materials to generate an electrical current when exposed to mechanical stress. You probably interact with piezoelectric technology every day without knowing it. Piezoelectric materials are deployed in many touchscreen devices, where your finger provides the stress. As deployed in the new dryer, the stress comes in the form of sound waves.

GE has accumulated a considerable body of knowledge in the field of applied piezoelectricity, which explains why the company partnered with Oak Ridge in this particular energy-efficiency project.

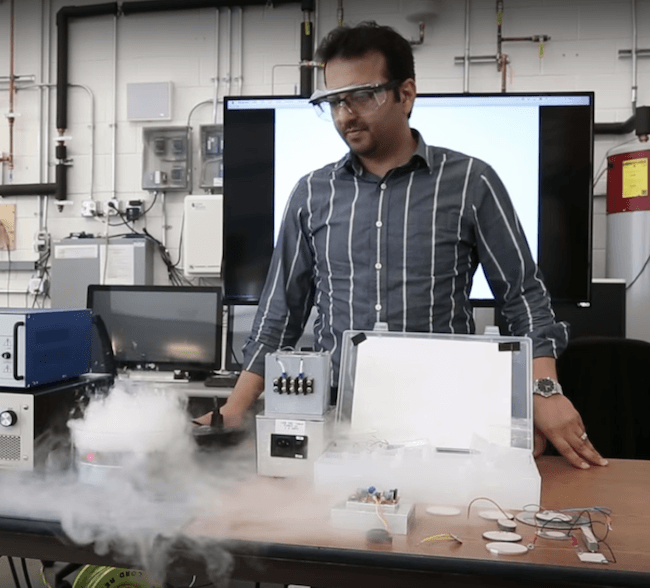

Oak Ridge is known for its foundational research on piezoelectric materials, and an Oak Ridge scientist, Ayyoub Momen, is credited with coming up with the concept for the ultrasonic dryer.

Image credit (screenshot): Oak Ridge's Ayyoub Momen with prototype piezoelectric dryer, US Department of Energy via YouTube.

Tina writes frequently for TriplePundit and other websites, with a focus on military, government and corporate sustainability, clean tech research and emerging energy technologies. She is a former Deputy Director of Public Affairs of the New York City Department of Environmental Protection, and author of books and articles on recycling and other conservation themes.