Aiming to advance development of efficient-vehicle technologies, the U.S. Department of Energy last week announced it will provide $55 million in funding for 31 projects “to accelerate research and development (R&D) of critical vehicle technologies that will improve fuel efficiency and reduce costs.”

Much of the funding is being devoted to projects that, in one way or another, will help realize the goals set out in President Barack Obama's EV Everywhere Grand Challenge. Announced in March 2012, the challenge aims to reduce the costs and improve the performance of plug-in electric vehicles (PEVs) to the point where they “are as affordable and convenient as today's gasoline-powered vehicles by 2022.”

DOE has invested $225 million in EV Everywhere projects to date in order to lower PEV costs, increase range and develop a PEV charging infrastructure. Among other achievements, EV Everywhere R&D projects have cut the cost of PEV batteries nearly in half, to $325/kilowatt-hour (kWh), since 2010.

The EV Everywhere Grand Challenge

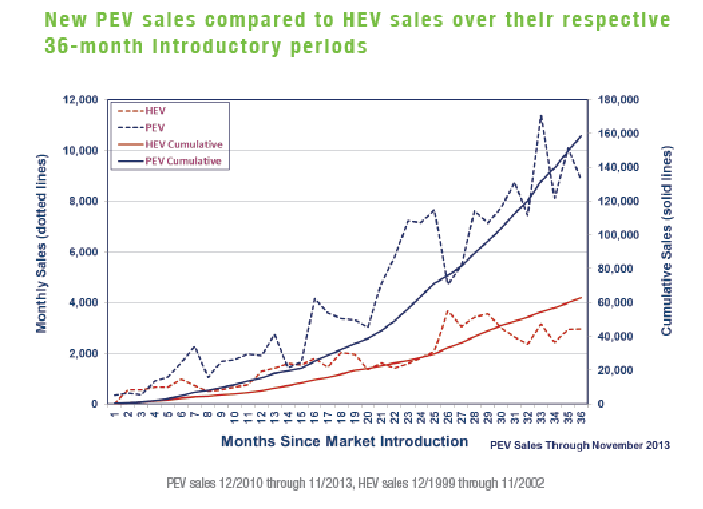

As DOE highlights in The EV Everywhere Grand Challenge: Road to Success, its first program assessment report, consumer acceptance of PEVs is on the rise: Nearly 100,000 PEVs (97,000) were sold in 2013, nearly double that of 2012. More than 50 companies have joined the DOE's “Workplace Charging Challenge,” pledging to provide PEV charging at more than 150 sites.

Nineteen of the 31 projects in the latest EV Everywhere funding round aim to reduce the cost and improve the performance of key PEV components. These include development of next-generation PEV batteries that go beyond lithium by making use of higher-energy-storage materials; developing and commercializing wide bandgap (WBG) semiconductors that can improve performance and reduce the cost of vehicle power electronics; and the development of lightweight materials that can reduce energy use and increase the driving range of PEVs.

In its latest round of efficient-vehicle funding, DOE is also funding 12 projects that aim to develop and demonstrate dual-fuel, or bi-fuel, technologies that reduce petroleum consumption, speed up growth in affordable, high-efficiency engine and powertrain systems for light-duty vehicles, and accelerate the introduction of advanced lubricants that can enhance vehicle efficiency today and in the future.

Commenting on the latest round of R&D funding, DOE Secretary Ernest Moniz said:

“Investments in the next generation of vehicle technologies will both strengthen our economy and lead to a more fuel efficient, clean energy future. Improving vehicle efficiency is instrumental to establishing a 21st century transportation sector that creates jobs as well as protects future generations from harmful carbon emissions.”

Moving beyond lithium

Reducing the cost and enhancing the performance of PEV and PHEV (plug-in hybrid) battery technology is a focal point for EV Everywhere R&D -- the 2022 target being to bring costs down to $125/kWh and boost performance to 400 Wh/liter, 250 Wh/kg and 2,000 W/kg. As DOE highlights in a press release:

Sales of PEVs grew 30 percent year-over-year during 2014's first half, while the cost of battery technology has dropped 60 percent since 2009.

Joining the DOE in the latest round of efficient-vehicle R&D funding, the Department of the Army is providing $3.7 million in co-funding for projects focused on moving beyond lithium-ion battery technologies, as well as reducing powertrain friction and wear.

“Partnering with the Energy Department, we are accelerating the development and deployment of cutting-edge technologies that will strengthen our military, economy, and energy security,” Dr. Paul Rogers, director of the U.S. Army Tank Automotive Research, Development and Engineering Center, was quoted as saying.

Moving beyond lithium-ion

Looking to go beyond current lithium-ion battery technology, results from the Battery Performance and Cost (BatPaC) model developed at Argonne National Laboratory indicate that the EV Everywhere PEV cost target can be reached using a combination of lithium- and manganese-rich high-energy cathode (LMRNMC) and silicon alloy anodes. The model also indicates the target can be reached using PEV batteries with silicon alloy anodes and lithium metal batteries.

In the latest funding round, DOE is providing a total of $7.77 million for six R&D projects that aim to go beyond lithium-ion technologies. Recipients include the boards of trustees of the Leland Stanford Junior University, Liox Power of Pasadena, Michigan State University, the State University of New York at Binghamton, the University of Maryland and the University of Pittsburgh.

Boosting the performance and reducing the cost of electric drive systems is another focal point of the EV Everywhere Grand Challenge. The 2022 targets are to bring costs down to $8/kW and to realize performance goals of 1.4kW/kg specific power, 4.0 kW/L power density, and 94 percent system efficiency, which translates to a cost of $440 for a 55-kW electric drive system, according to the DOE.

*Images credit: U.S. Department of Energy (DOE)

An experienced, independent journalist, editor and researcher, Andrew has crisscrossed the globe while reporting on sustainability, corporate social responsibility, social and environmental entrepreneurship, renewable energy, energy efficiency and clean technology. He studied geology at CU, Boulder, has an MBA in finance from Pace University, and completed a certificate program in international governance for biodiversity at UN University in Japan.