It's time for a fresh look at fast fashion. Trendy, affordable brands like H&M, Uniqlo and Zara are often criticized for perpetuating waste by encouraging consumers to buy clothes to match the trend of the season. Indeed, Americans landfilled 19 million tons of textiles in 2013 (PDF). That's 16 pounds of textile waste for every American. But what if the fibers in those clothes could be separated and repurposed into new garments? If the industry creates a closed loop, the waste problem is lessened substantially.

H&M has made a big splash in the clothing recycling community with its partnership with I:CO. The company's goal is to create a closed loop for fashion. It's a pretty audacious goal -- one the retail clothing giant hasn't quite figured out how to meet -- but it's doing it anyway. Clothing collected from drop bins located in every H&M store is sorted, and items that can't be reused are disassembled down to the basic fibers. These fibers can be rewoven into cloth to sew new clothes. Customers are incentivized to participate with coupons and discounts on their purchases.

I sat down with H&M's global sustainable business expert, Pierre Börjesson, at BSR 2015 to get the lowdown on the program. Börjesson explained that there's a large consumer base that loves fashion and wants to lighten their impact too. The company wants to meet them where they are and give them a better product.

To that end, H&M has committed to collecting used clothing in all of its stores around the world and processing it down to the fiber level to figure out how to reuse it. The company may not have the entire loop fully closed, or even know exactly how it's going to get that way, but it's going to try. It's a moral imperative. As Börjesson explained to me when talking about the steps his competitors are taking: "I can understand how a company may not know how to do this, but that's no excuse for not jumping in."

I asked about the "fashion/impact" nexus -- is there a point at which it's too environmentally intensive to process clothes for reuse? Börjesson reminded me that it would probably always be a lower environmental impact than growing cotton from seed with the pesticides and water needed to produce a high-quality crop and gin it to make it useable in the manufacturing process. Touché.

The challenge

H&M is trying to build a market for fiber processing. As Andrew Morlet, CEO of the Ellen MacArthur Foundation, explained during a BSR panel on the circular economy: "We want clothing to be more like paper – technical, biological fiber that can work in a reusable system."

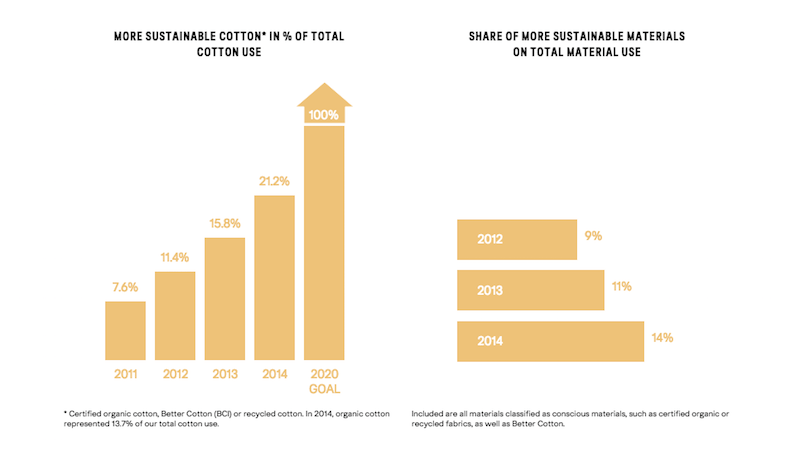

For H&M, cotton in particular is a challenge. It's the fiber the company buys the most, and it's delicate. The fibers break easily in the recycling process -- making it difficult to use to produce the same high-quality fabric. But that has not stopped H&M. The company has committed to 100 percent sustainable cotton by 2020. This is a big step up from current levels -- 21 percent sustainable cotton in 2014. Fourteen percent of total materials are sustainable overall, and cotton is the biggest share of textiles.

Sustainable cotton includes post-consumer recycled cotton, certified organic cotton and cotton from the Better Cotton Intiative. Recycled cotton and polyester is currently in use -- up to 20 percent of the fibers in the final product. Those numbers will improve over time as processes improve, Börjesson was quick to explain, and I agree with him. Don't believe me? Look at the recycled paper industry. It once wasn't possible to even find 100 percent post-consumer recycled paper, but now it is very high-quality and easy to find at any office supply store.

Another big challenge is mixed materials like cotton-poly blends. While these garments are more difficult to disassemble, the blending improves durability, so we don't want to throw the baby out with the bathwater. Börjesson said: "If we start to design for disassembly [favoring 100 percent cotton or 100 percent polyester over the mix], we reduce durability, so we need to figure out how to disassemble efficiently. [We] want high-quality fibers to reuse."

As Morlet put it: "We need to think about materials as technical flows in a natural system. We make packaging that lasts in recognizable forms for 400 years. It’s a design problem."

Reinventing the system to create a closed loop is a big undertaking, but H&M is approaching it in the correct manner: focusing on customer engagement and education, materials collection, breakdown, and incorporation into new products all at once. Each step must improve, and the company can only improve incrementally, but the entire cycle represents a sea change in the industry.

For example, once the used clothing is collected, all the sorting is quite labor intensive. It must be done manually, which is expensive. I:CO is working with H&M to research and develop mechanical solutions to solve this problem, which will make recycling programs easier to scale.

Becoming a clothing recycler has cost H&M money, but that does not mean that it's a cost center. As Börjesson puts it, this project is an investment in a future opportunity -- to develop the processes that will turn waste into gold and a competitive advantage for the company. There's a lot of room for improvement given that 85 percent of textiles currently end up in a landfill. That's one of the poorest recycling rates of any reusable material.

H&M is really on to something when it says there's no rule in fashion but one: Recycle your clothes.

https://www.youtube.com/watch?v=s4xnyr2mCuI

Jen Boynton is the former Editor-in-Chief of TriplePundit. She has an MBA in Sustainable Management from the Presidio Graduate School and has helped organizations including SAP, PwC and Fair Trade USA with their sustainability communications messaging. She is based in San Diego, California. When she's not at work, she volunteers as a CASA (court appointed special advocate) for children in the foster care system. She enjoys losing fights with toddlers and eating toast scraps. She lives with her family in sunny San Diego.