About 80 percent of California’s water sustains agriculture, but Sacramento is putting the onus on the state’s businesses and residents to find even more ways to conserve this precious resource. One sector scrambling to find even more ways to conserve water is Los Angeles’ denim industry. Of the approximately 40,000 people the garment and fashion industries employ in Los Angeles County, many work for companies that design and sell high-end blue jeans that are sold across the country and exported around the world.

These companies have already been challenged because of past threats of a European tariff on American denim jeans, as well as the constant specter of jobs going overseas in the name of slashing costs. Denim manufacturers and blue jeans designers in the Southland, however, continue to be resilient. But now concerns over water restrictions due to the California drought have put many of these companies on edge.

The push to conserve water began long ago at the start of the industry’s supply chain. Companies such as 10-year-old Blue Creations, a denim manufacturer in Carson, have started to use alternative methods to treat denim other than using copious amounts of water. Machines that use ozone in place of some, if not all, water used in treatments such as stonewashing have reduced the need for water, chemicals and energy. Other companies, including American Apparel, began to incorporate more low-impact dyes that have little or no toxic chemicals into their manufacturing processes. Such dyes have a higher fabric absorption rate, nixing the need for mordants, the substances that help affix dyes to textile fibers.

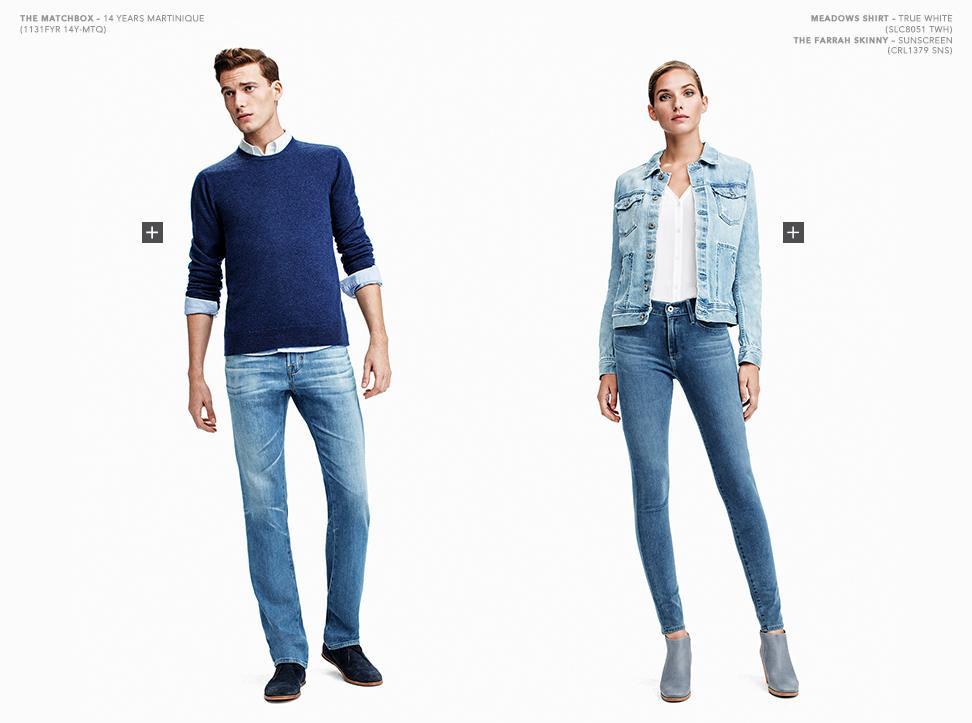

One of the larger denim manufacturers and designers in the Los Angeles area is AG Jeans, a popular brand that offers jeans that cost up to US$300. The company has already tried to minimize its environmental impact through the use of more sustainable fibers, such as Tencel and Modal, and has invested in technologies in order to reduce its water consumption. According to the company, its use of ozone technology to treat denim has saved millions of gallons annually — 50 percent since implementation in 2010.

Companies such as AG Jeans face many challenges in order to meet the expectations of quality their customers demand because those buyers are not necessarily focused on the sustainability of their garments. At the same time, they are offering decent paying jobs in a sector that has largely departed from the United States. Onerous water restrictions and the threat of higher rates -- and even fines for excessive water use -- could push these companies to lay off local employees and move overseas, perhaps to countries with lax regulations that are also suffering from water scarcity.

One California company that does not manufacture jeans in Los Angeles but has been ahead of the curve when it comes to water conservation is Levi Strauss. The company claims its “Water<Less” process has saved 1 billion gallons of water since 2011. But Levi’s has also tried to educate consumers about how they can be more water savvy by pointing out that blue jeans have a water impact long after their point of sale. Emphasizing the point that excessive washing is actually detrimental to the quality of denim, the company’s CEO urged its customers to “stop washing your jeans” at a sustainability conference last year.

As the old saying goes, competition is good for the marketplace. Companies such as Levi’s have an opportunity to share their best practices and ideas with smaller firms, which in the long run could strengthen the industry and help it remain a vital part of California’s culture and, of course, economy.

Image credit: AG Jeans

Leon Kaye has written for 3p since 2010 and become executive editor in 2018. His previous work includes writing for the Guardian as well as other online and print publications. In addition, he's worked in sales executive roles within technology and financial research companies, as well as for a public relations firm, for which he consulted with one of the globe’s leading sustainability initiatives. Currently living in Central California, he’s traveled to 70-plus countries and has lived and worked in South Korea, the United Arab Emirates and Uruguay.

Leon’s an alum of Fresno State, the University of Maryland, Baltimore County and the University of Southern California's Marshall Business School. He enjoys traveling abroad as well as exploring California’s Central Coast and the Sierra Nevadas.